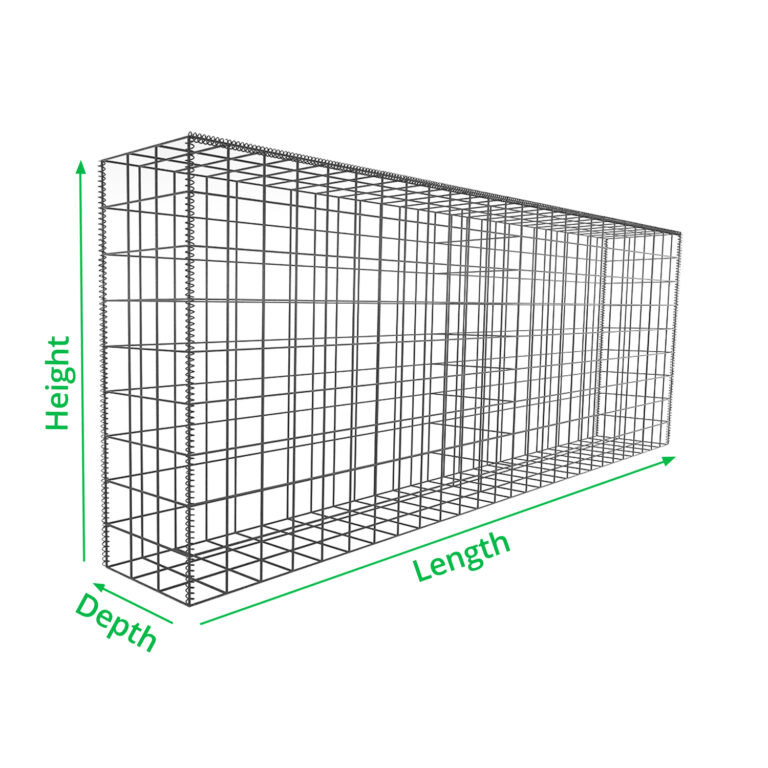

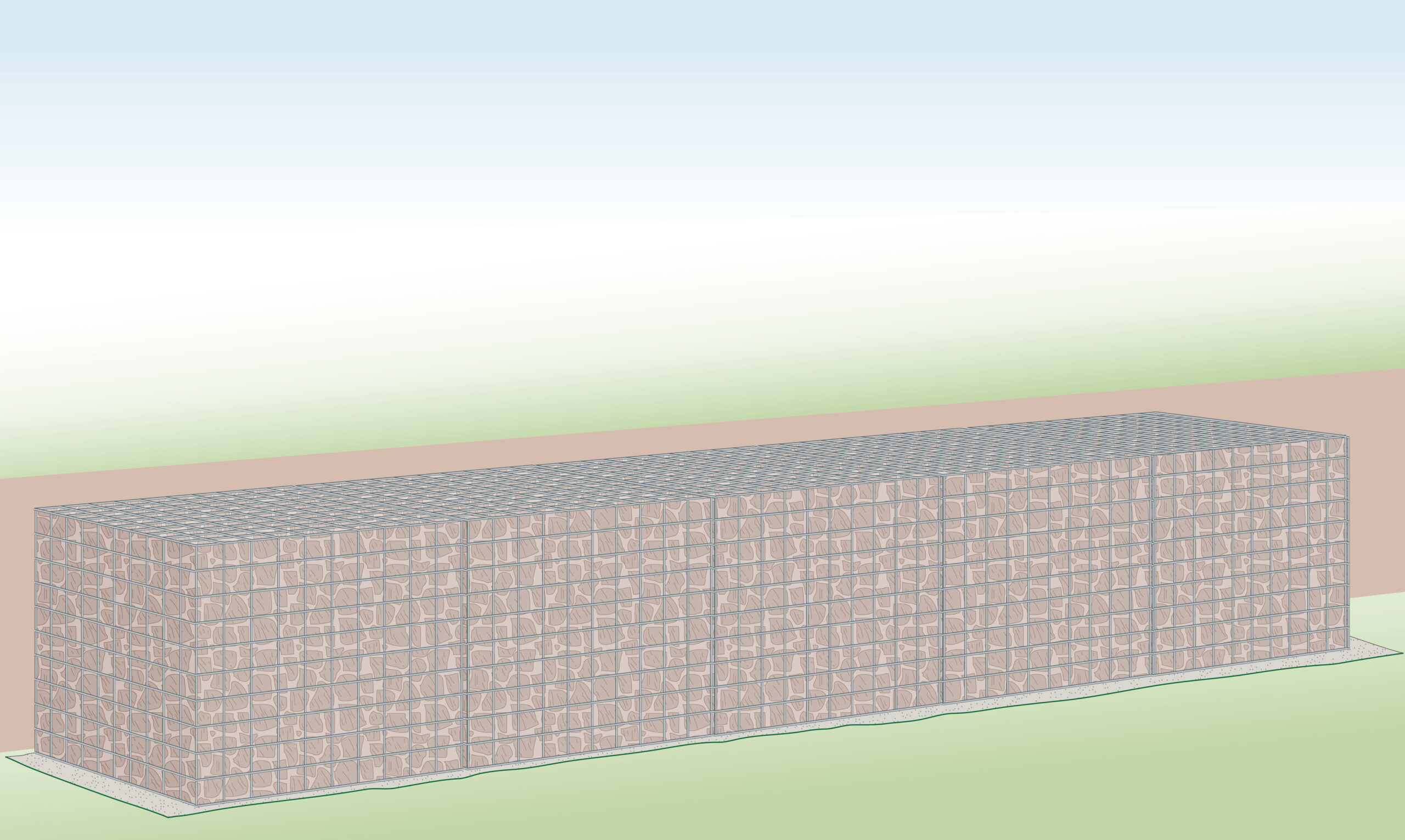

Gabion Wall (1m Tall)

Gabion wall kits include all the equipment and instructions needed to create a gabion wall up to 1m tall.

- Easy to install, no DIY experience necessary

- Manufactured in the UK, to BS EN standards

- BBA Approved

RELATED: cut to size gabions – wall builder – 2m walls

Helpful Information

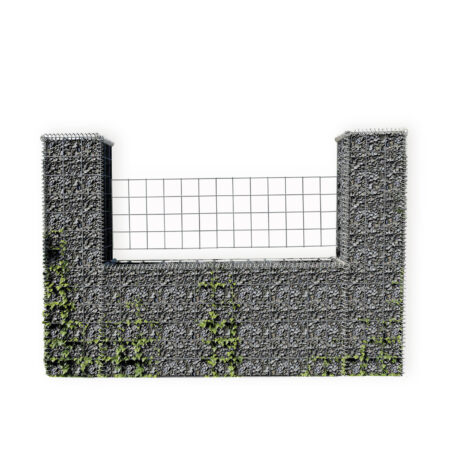

Customer Images

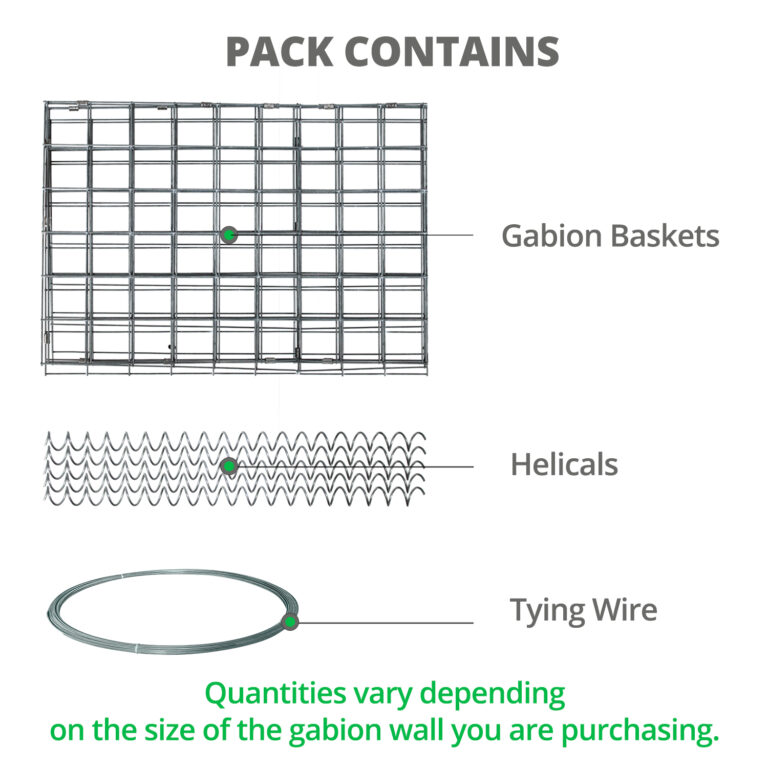

Gabion Kit Includes

| Included | Explanation |

| Full Installation Instructions | |

| Gabion Baskets |

– 1x 97.5cm long gabion basket will be included in your pack for every 97.5cm length of gabion wall ordered.

|

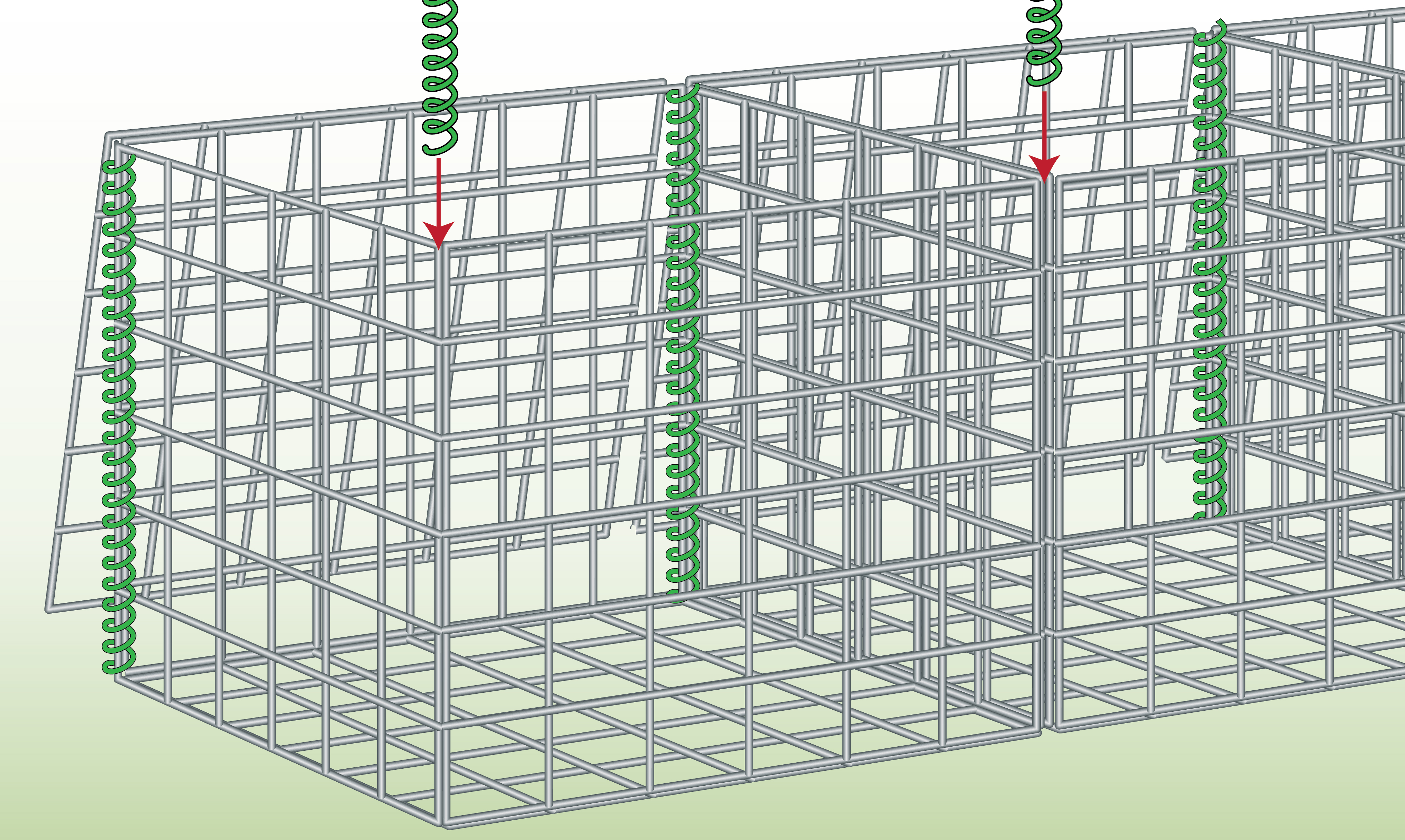

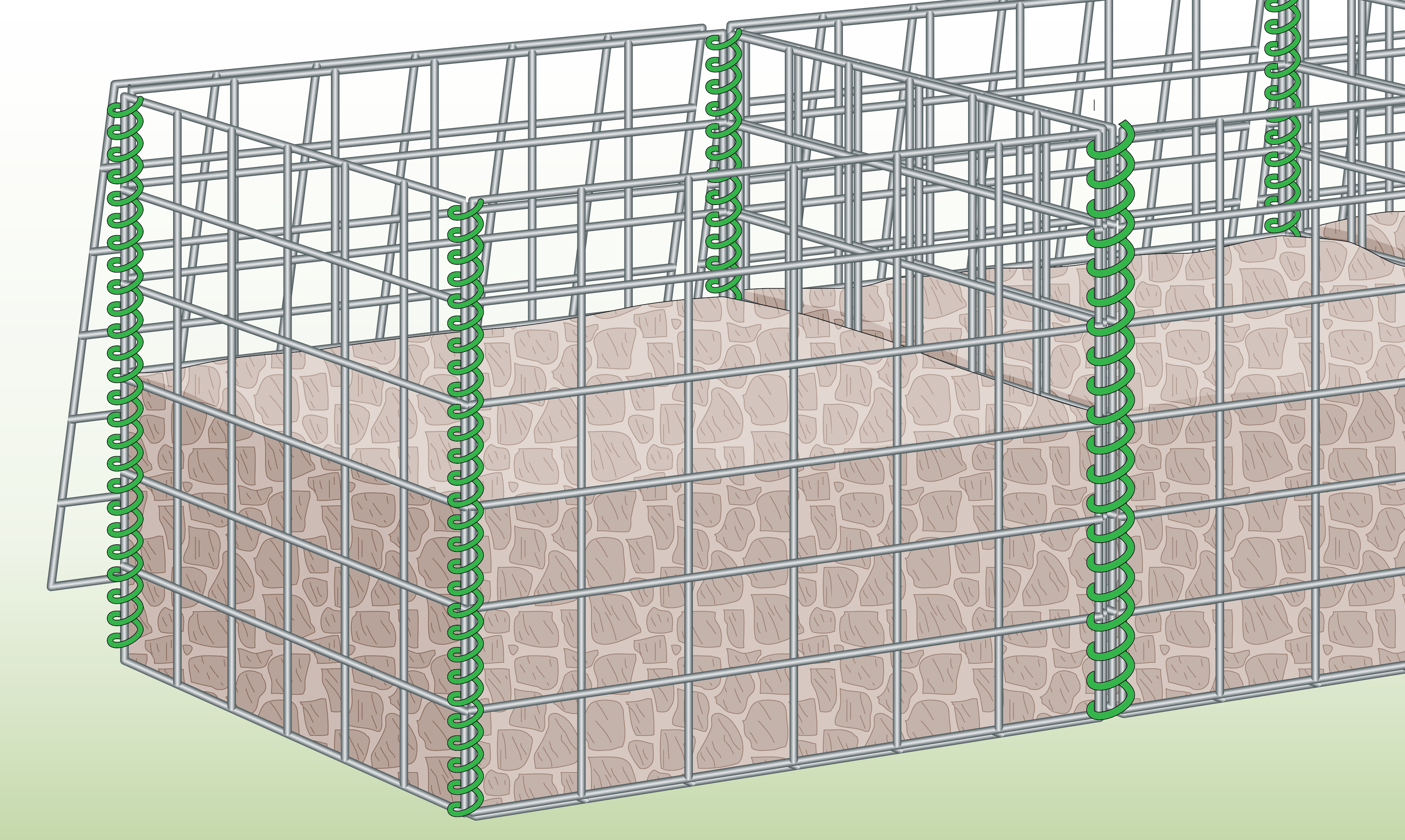

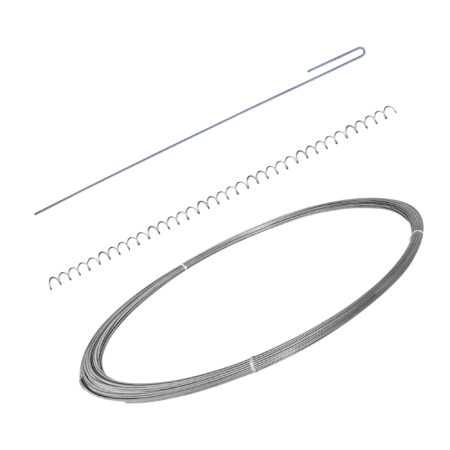

| Helicals |

– Helicals will be included so you can attach the corners and lids for all gabion baskets in your order. Helicals are 1m long so if your gabion baskets are under 1m, you will need to cut the helicals to size with a hacksaw or wire cutters.

|

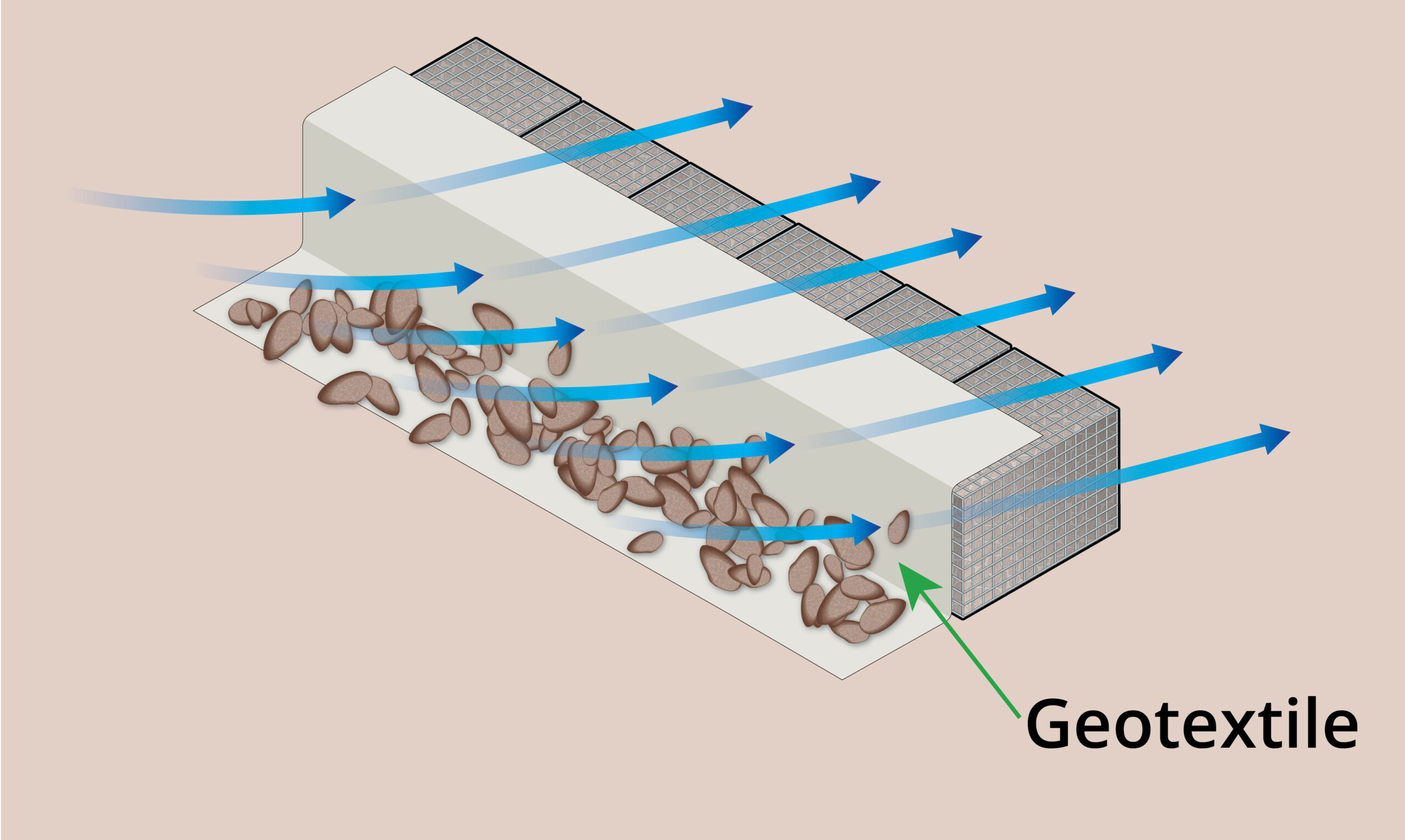

| Geotextile | If required, geotextile can be ordered separately. |

| Stone separating panels | If required, stone separating panels can be ordered separately |

| Stones | If required, gabion stone provided separately, jump to quantity guide |

| Tools | None required but you may need a spade and some gravel depending on the way you plan to install. For more information, jump to installation instructions (freestanding / retaining walls). |

Gabion Wall Overview

| Galfan Coated | PVC Coated | ||

| 4mm Wire Diameter | 5mm Wire Diameter | 4.3mm Wire Diameter | |

| Freestanding wall | |||

| Retaining wall | |||

| Can be walked on | |||

| Can be sat on | |||

| No bulges when filled with rocks | |||

| Erosion control | |||

| Residential areas | |||

| Public leisure area | Best | ||

| Delivered as | Flat packed, strapped to a wood pallet with option of small or large truck | ||

| Can wires be cut | Yes – with heavy duty wire cutters | ||

| Made in UK | Yes | ||

| Conforms to British manufacturing standard | BS EN 10223-8:2013 | ||

| Certificate of conformity | Yes – download | ||

| Construction | |||

| Mesh Hole Size | 75mm x 75mm | 75mm x 75mm | 75mm x 75mm |

| Mesh Material | Galfan coated steel | Galfan coated steel | Galfan coated steel with grey PVC coating |

| Mesh Construction | Welded | Welded | Welded |

| Mesh panels joined together by | Stainless steel C Clips | ||

| Strength and environment | |||

| Tensile strength range | 540-770 N/mm² | 540-770 N/mm² | 540-770 N/mm² |

| Corrosion resistance | Yes, conforms to British standard BS EN 10244-2:2009 | ||

| Abrasion resistance | Yes, conforms to EN 60229:2008 | ||

| Life Expectancy | 50 – 100 years | 50 – 100 years | 120 years |

| Suited to Environments | C2 – C4 | C2 – C4 | C2 – C5 |

| Rocks / Filling / Installation | |||

| Speed of installation | 2-5 mins each | ||

| Experience required to install | Easy install | ||

| Rock size required | Minimum 80mm x 80mm | ||

| Requires angular, interlocking rocks | No – these commercial grade gabions can be filled with any shape of stone without bulging. | ||

| Can be filled with crushed concrete | |||

| Can fill with rounded rocks | |||

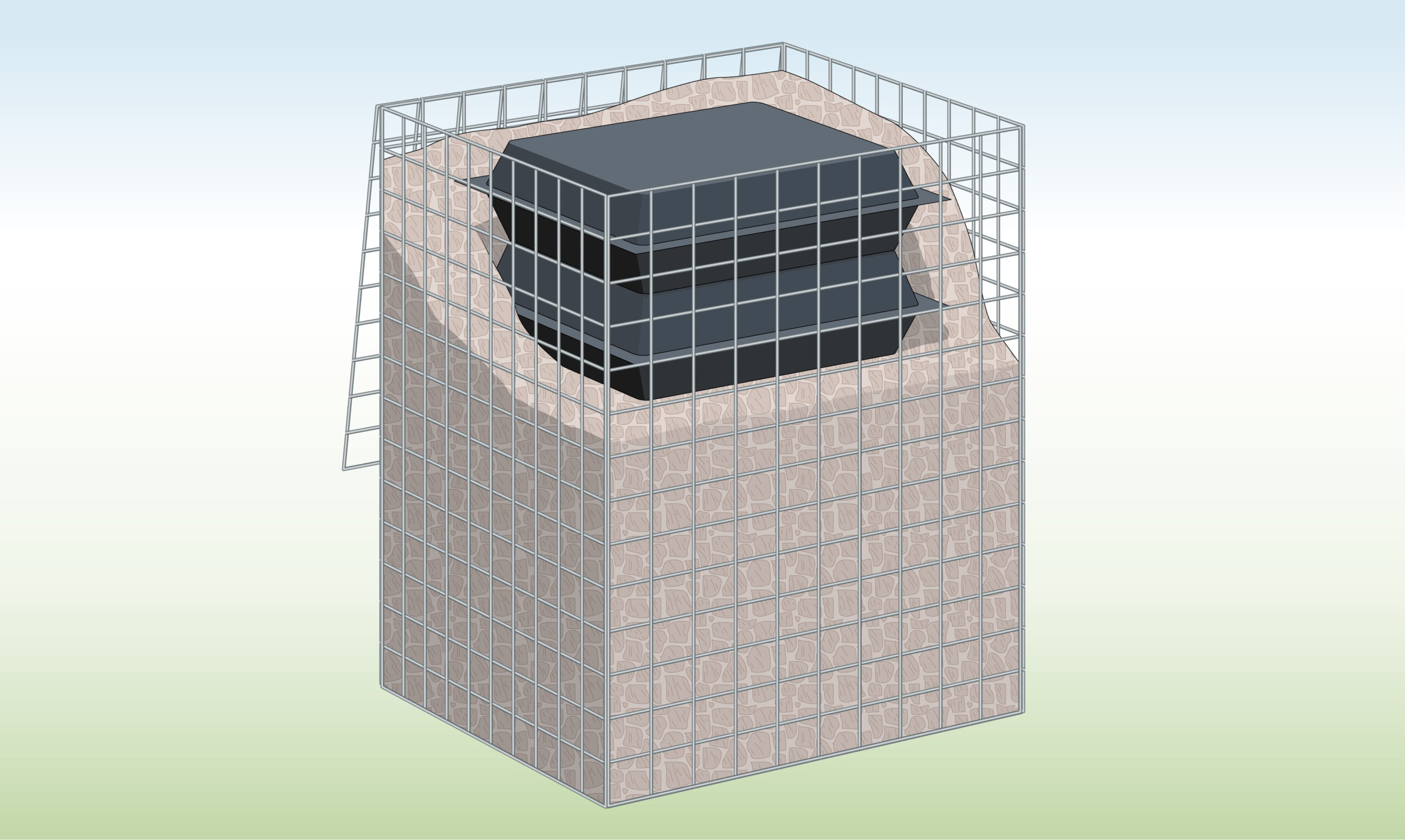

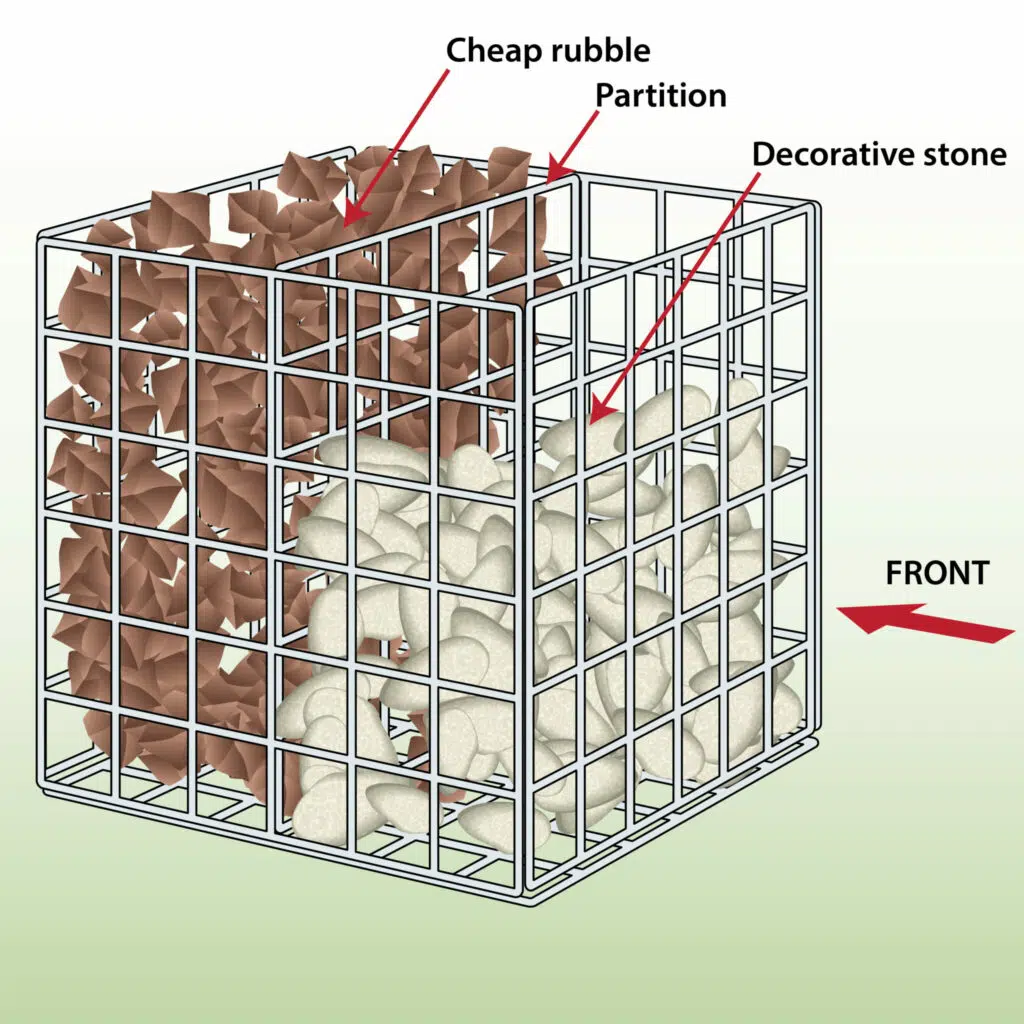

| Save money | Stone separating panel (ordered separately). Allows you to backfill the cages with cheaper stone or rubble | ||

Installation Instructions

Please use the following information as guidance only. If you are unsure about how to install your gabion wall, please contact a Civil Engineer.

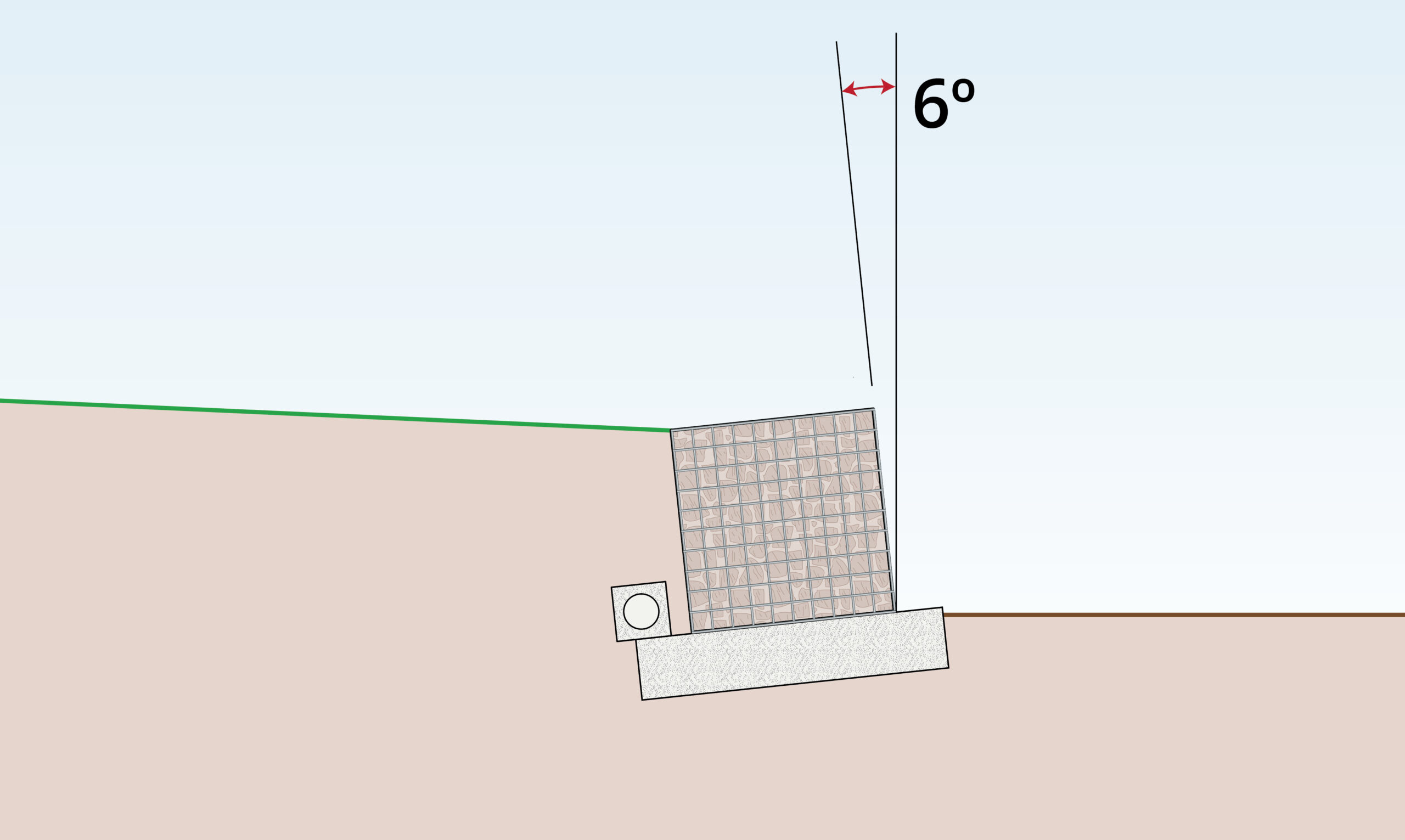

Freestanding Wall Instructions

Retaining Wall Instructions

| To Do | Explanation |

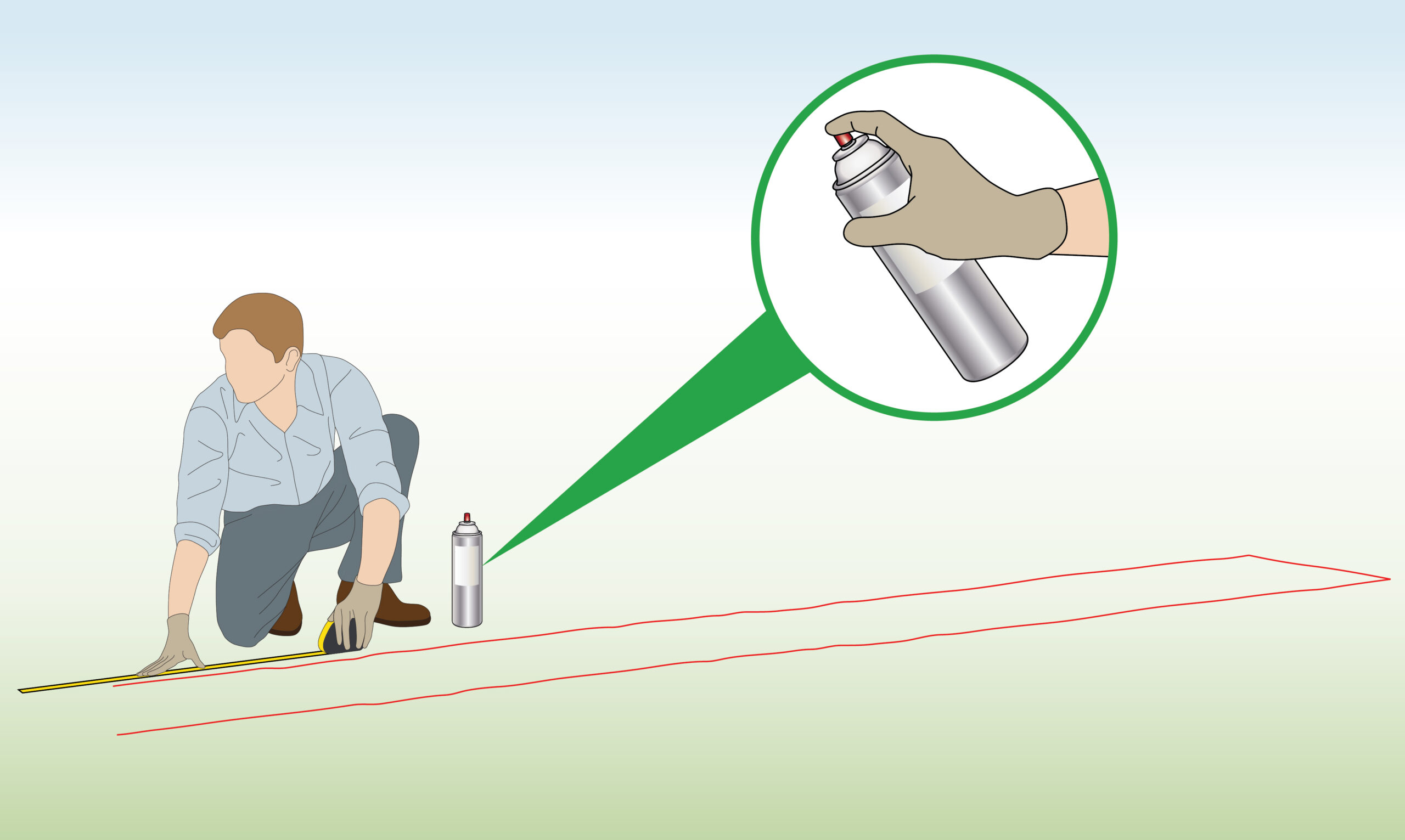

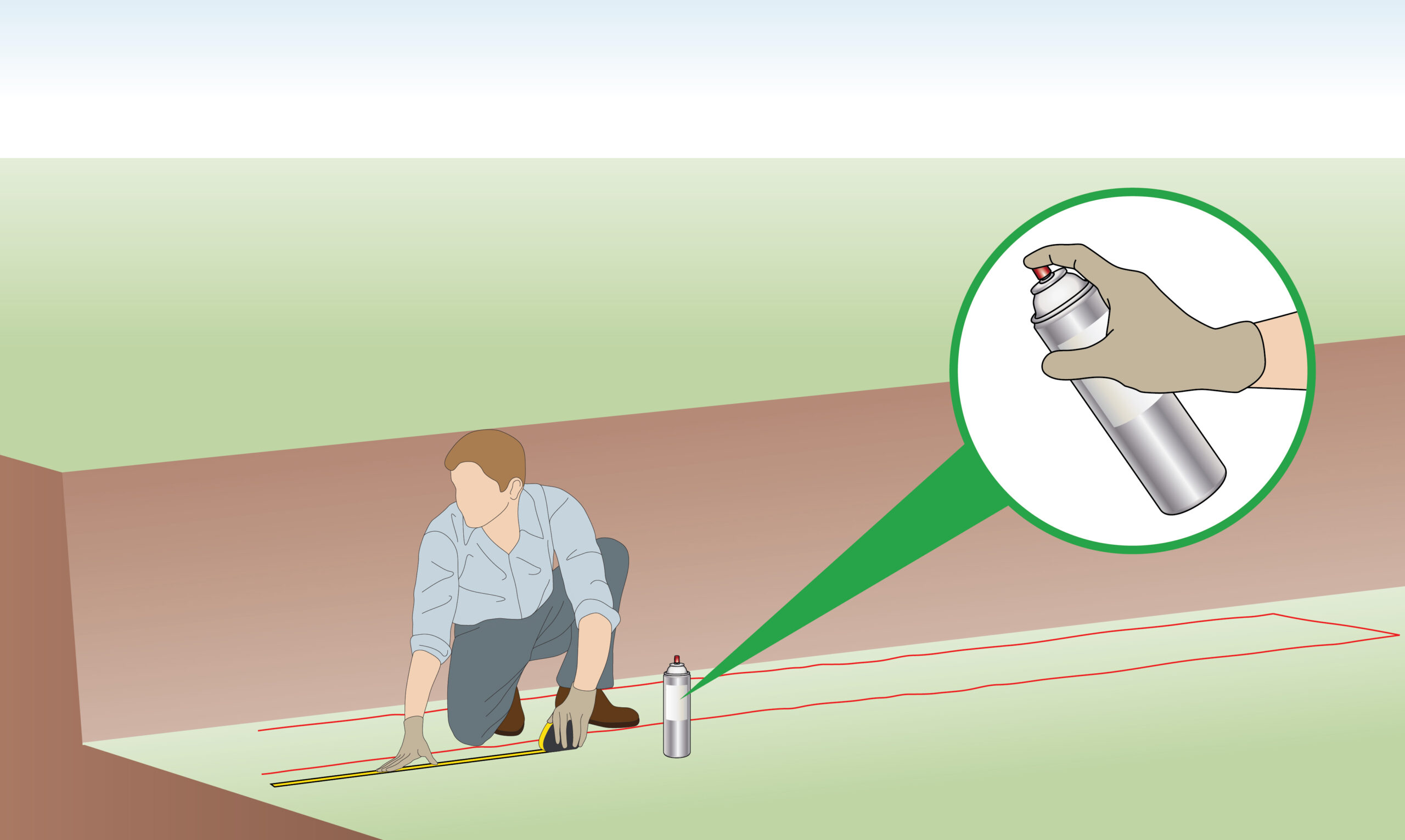

| Step 1 – Identify location

|

Use spray paint, stones or other materials to mark the location where you plan to construct your wall. |

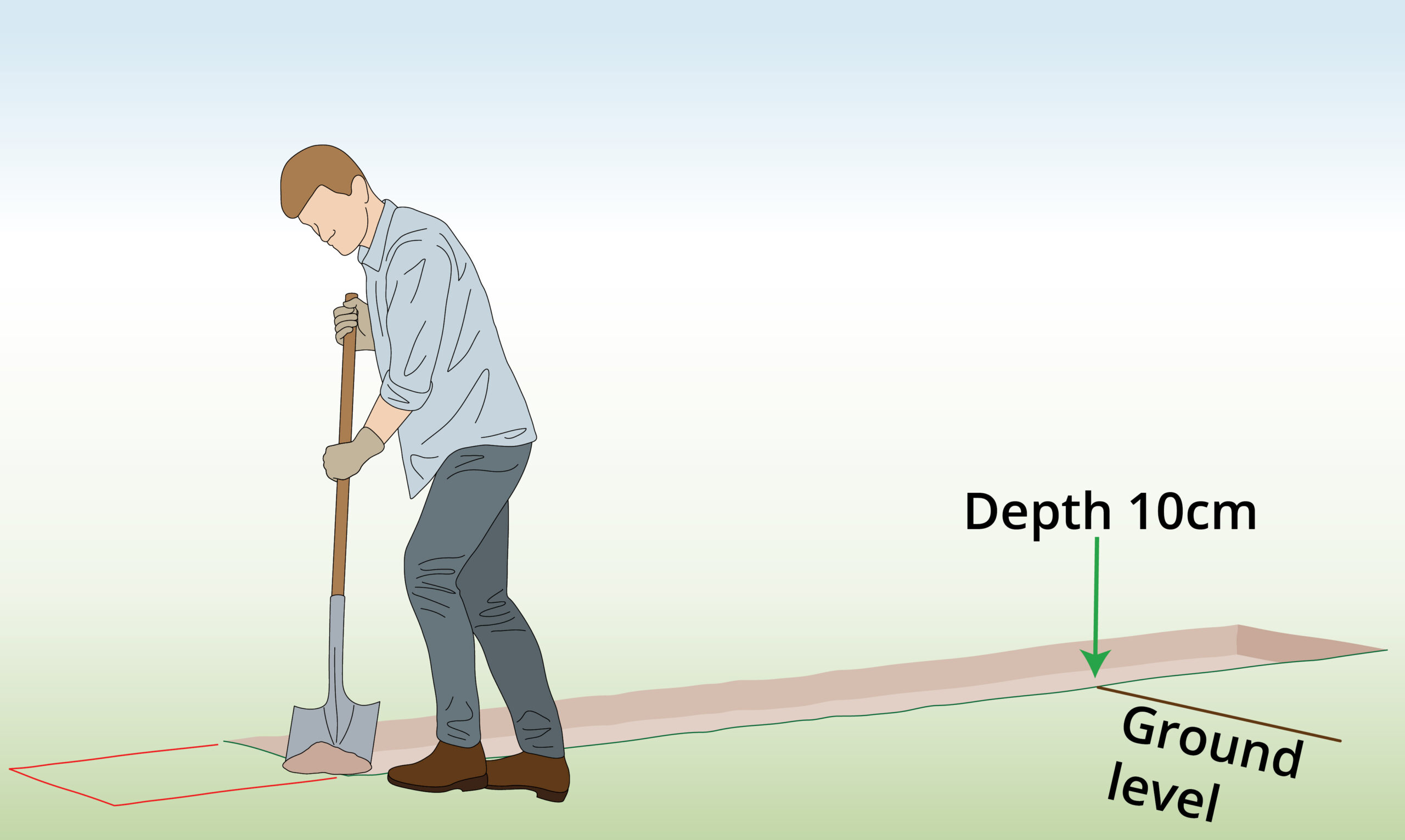

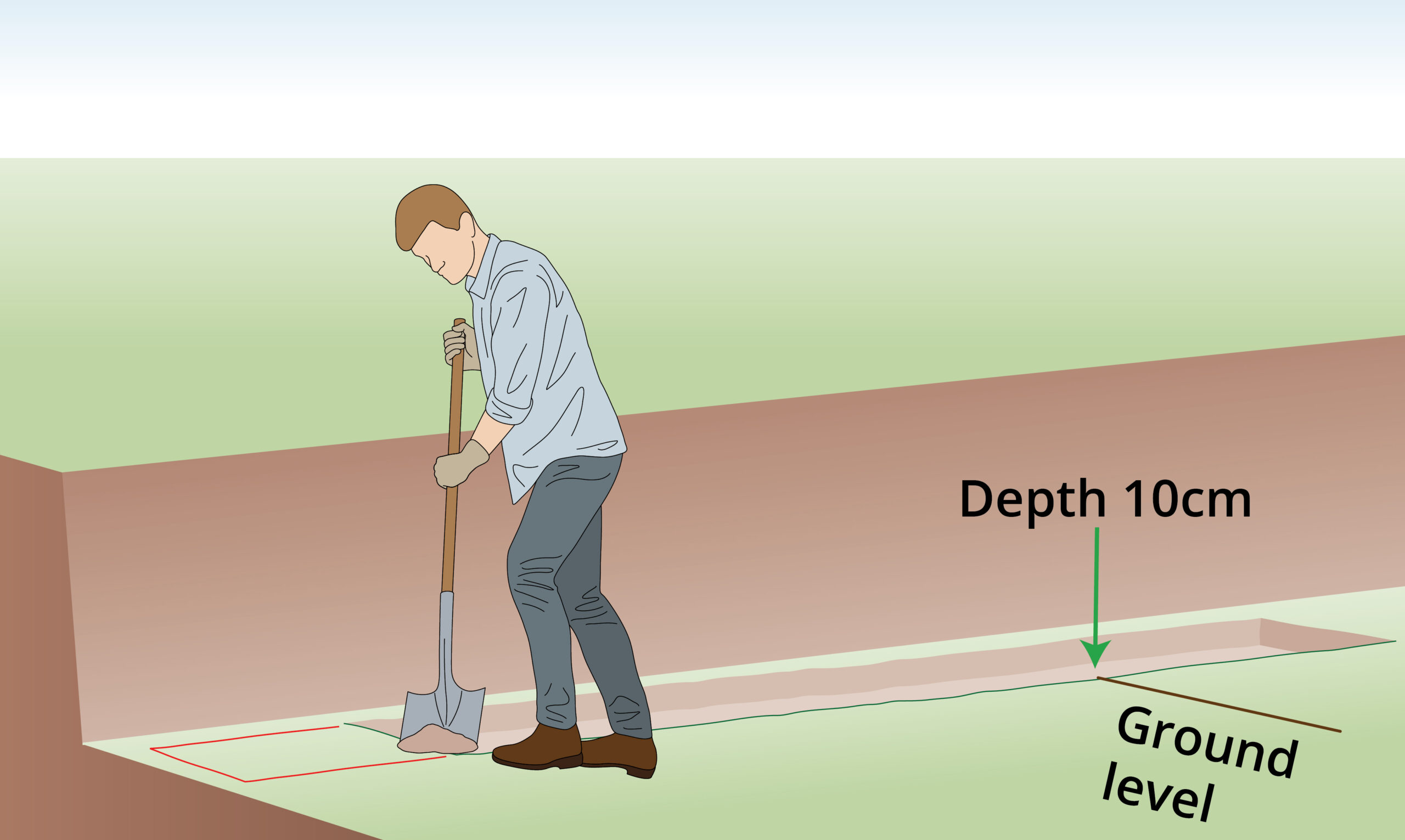

| Step 2 – Dig

|

Dig 10cm or until the ground is firm. Gabion walls lower than 1m are often placed directly on the ground but it will be more stable if placed on firm ground such as clay instead of the topsoil. |

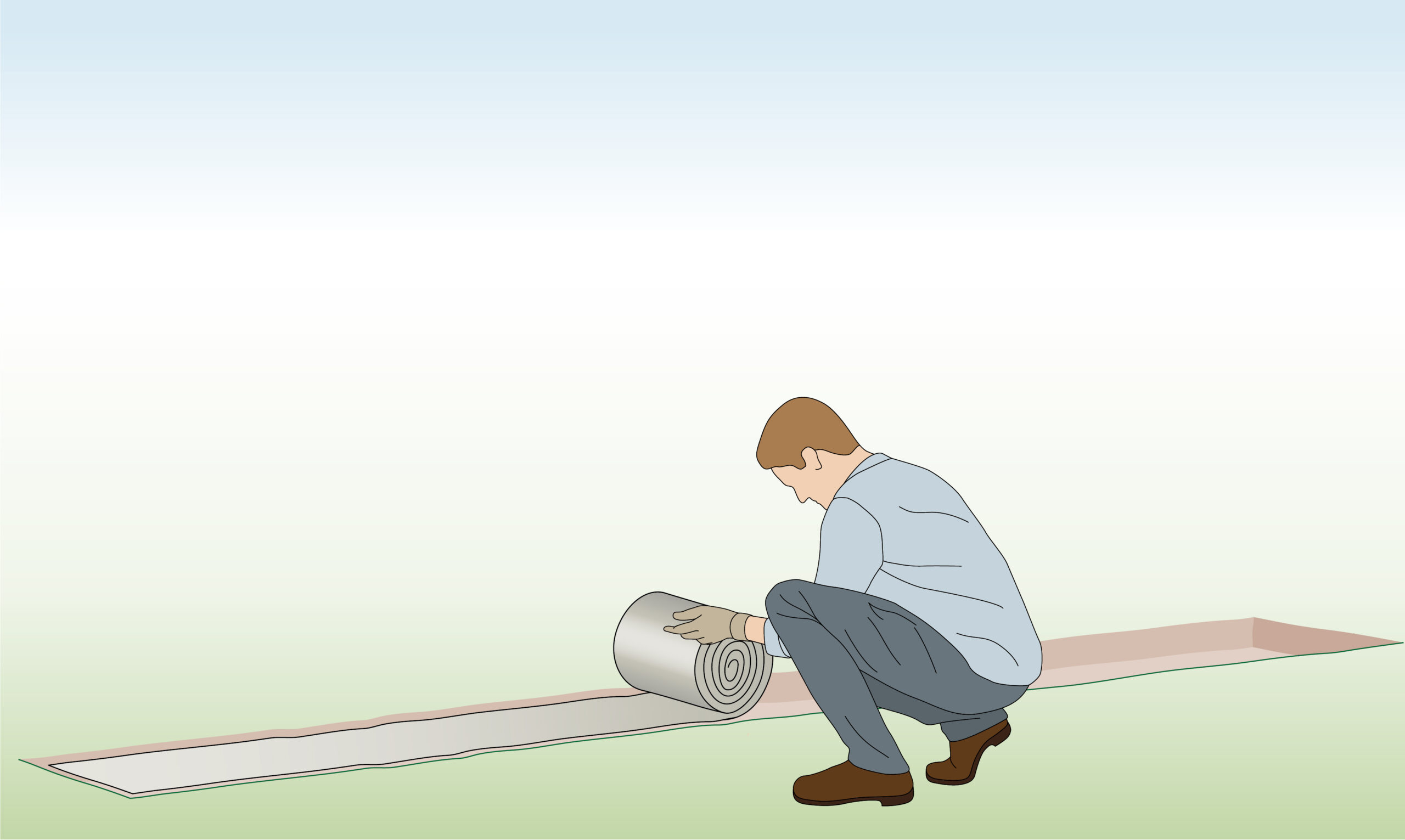

| Step 3 – Geotextile

|

Place a layer of geotextile or weed mat on the soil to prevent weeds from growing up and through your gabions. |

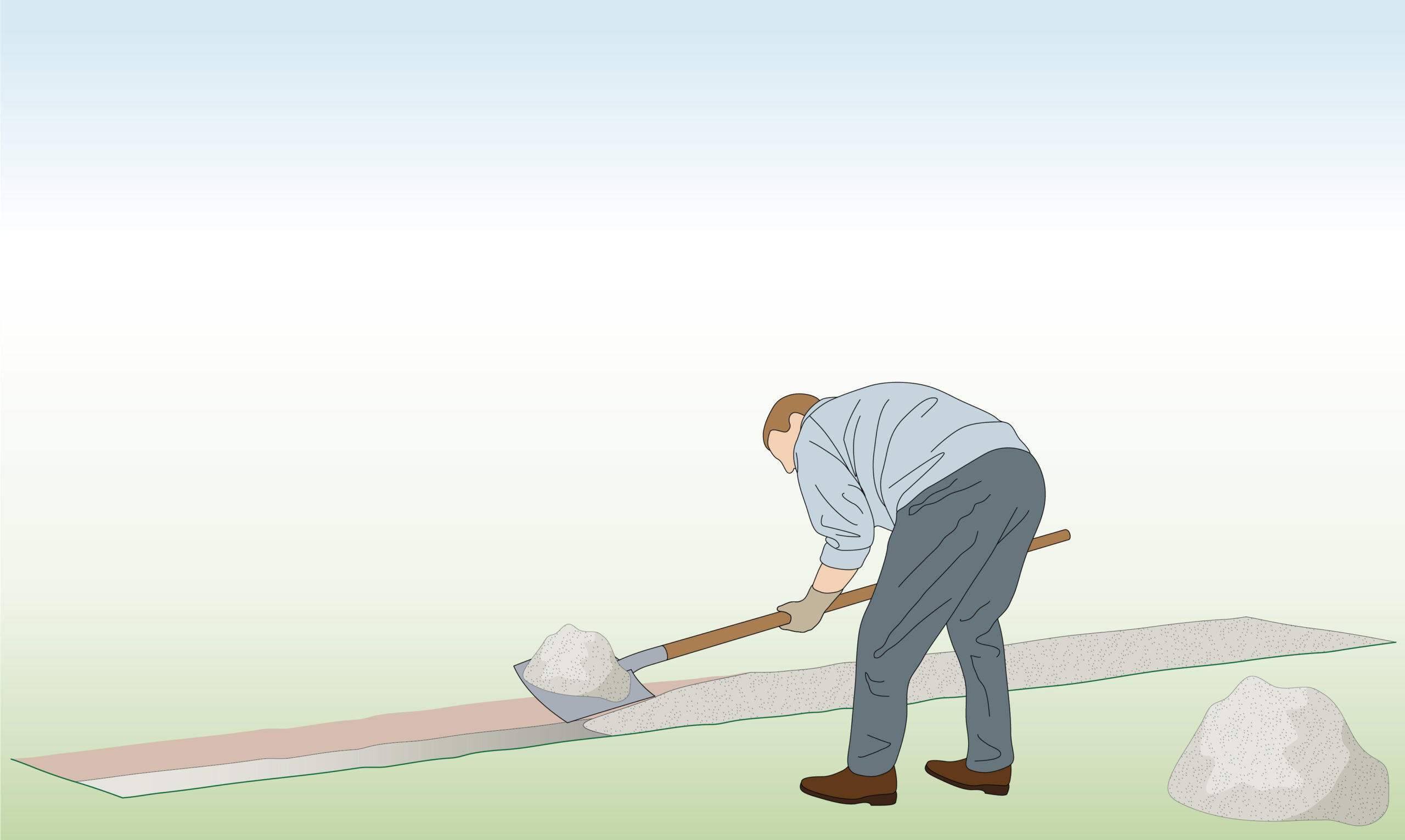

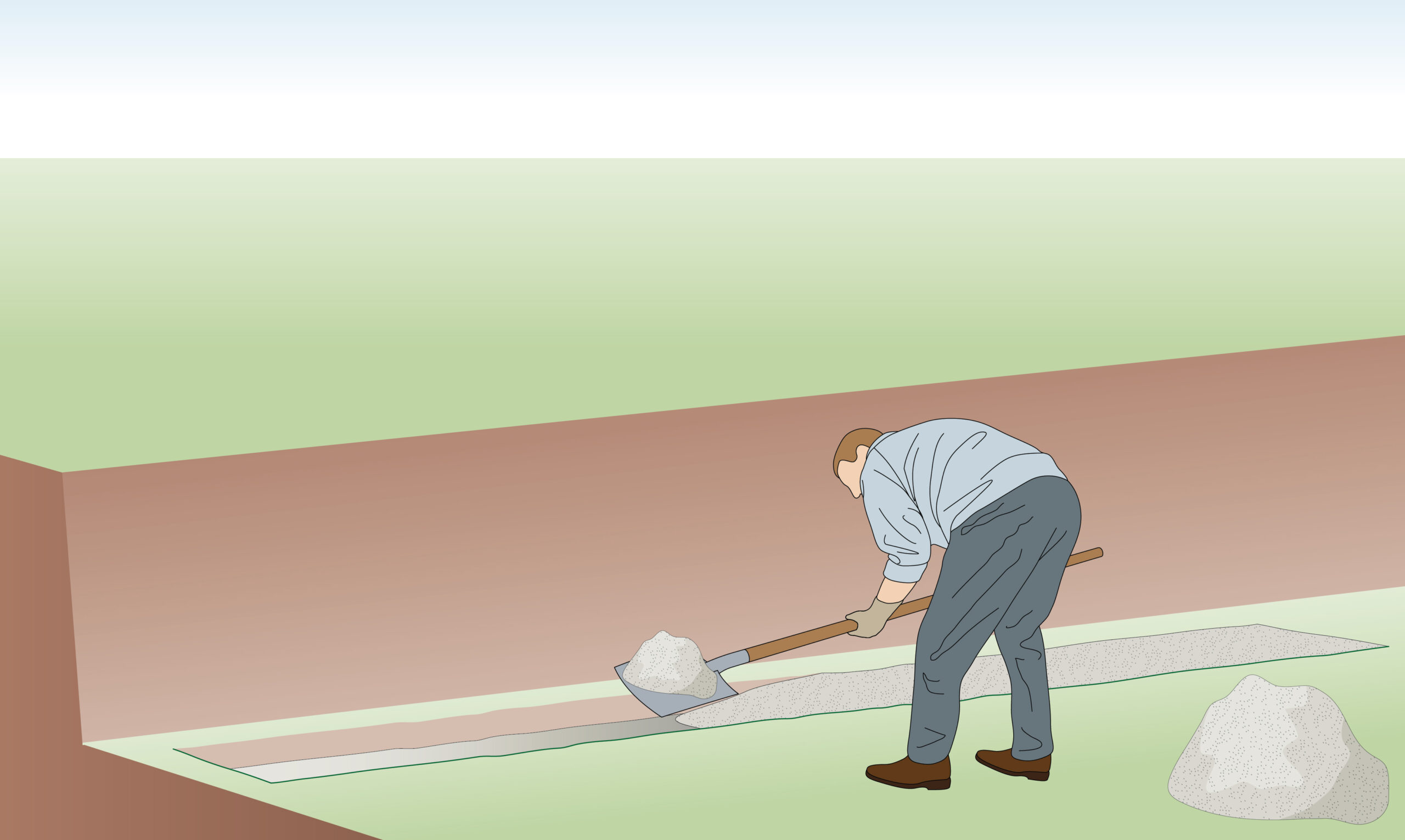

| Step 4 – Add Basecourse

|

Add a 10cm layer of gravel or basecourse on top of the geotextile. |

| Step 5 – Compact Gravel

|

Walk and stomp on the gravel to make it compact. |

| Optional – Concrete Foundation |

Most low-level gabion walls do not require a foundation but if you have a large amount of groundwater or the soil is weak, it may be needed. |

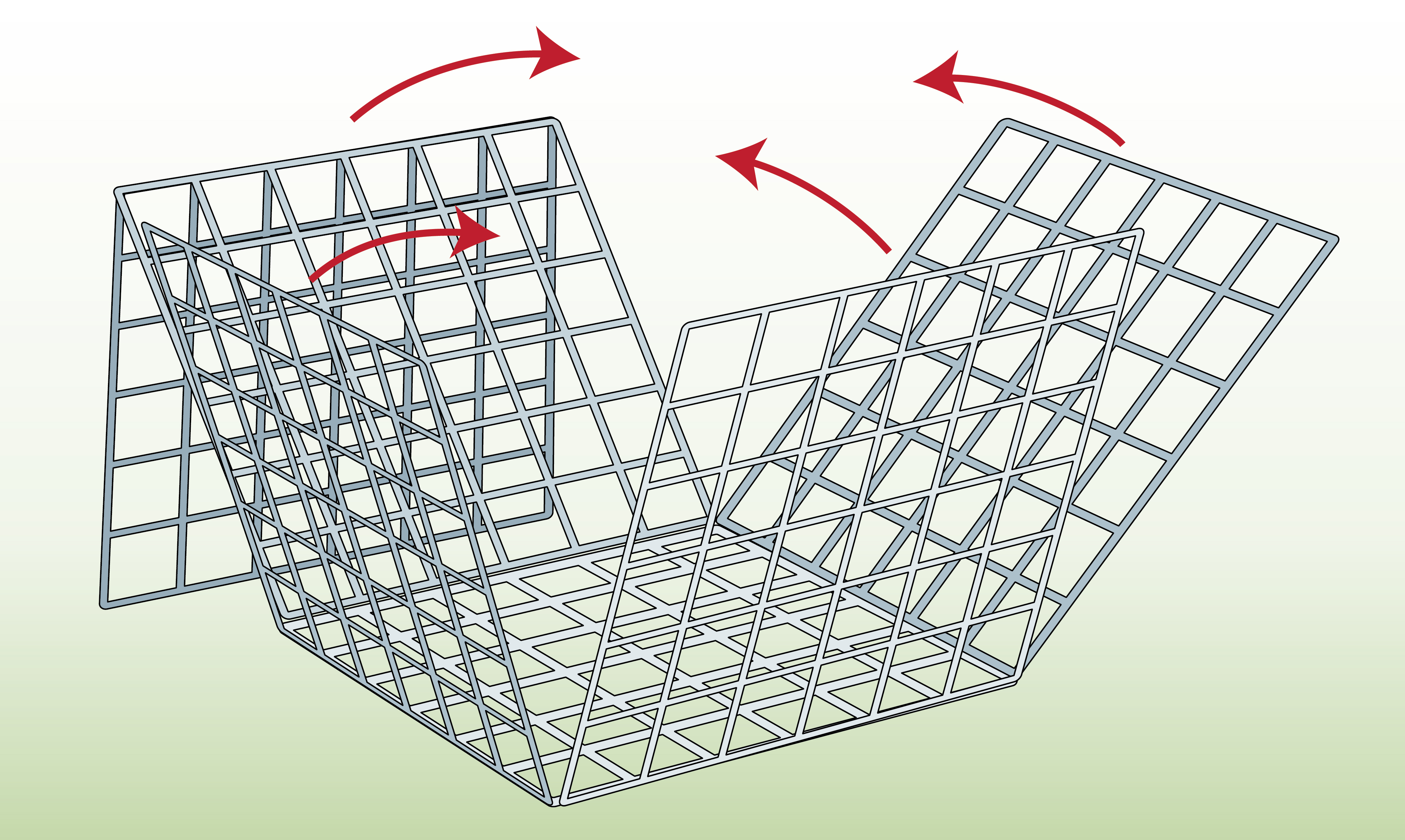

| Step 6 – Unfold the Baskets

|

Unfold and lift up the sides of the baskets. |

| Step 7 – Join the Cages

|

Assemble and attach the baskets together with the helicals included in the kit. |

| Step 8 – Fill with Stone

|

Fill the gabions with your choice of stone. |

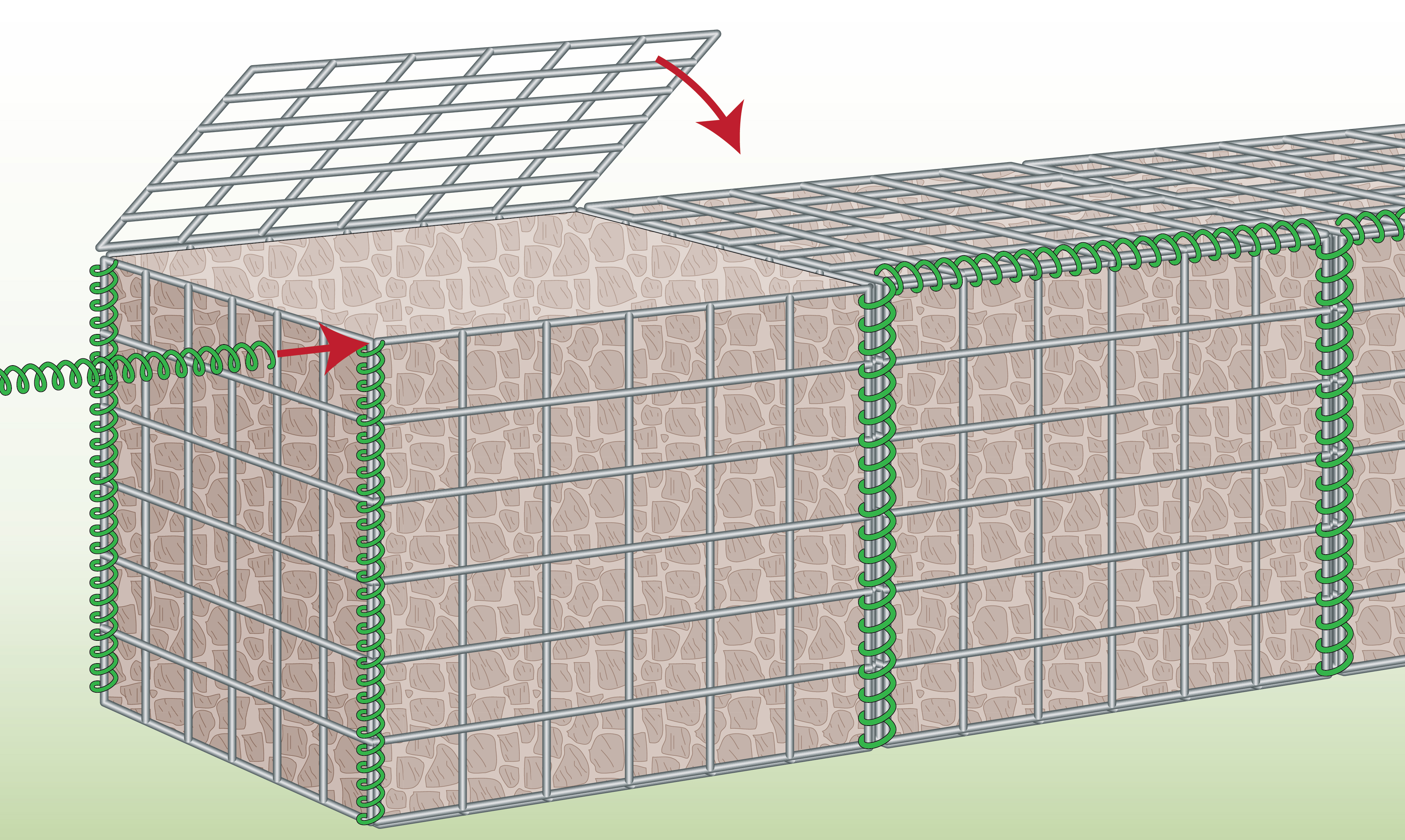

| Step 9 – Close Lids

|

Fold the lids down and close your baskets with the helicals provided in the kit. |

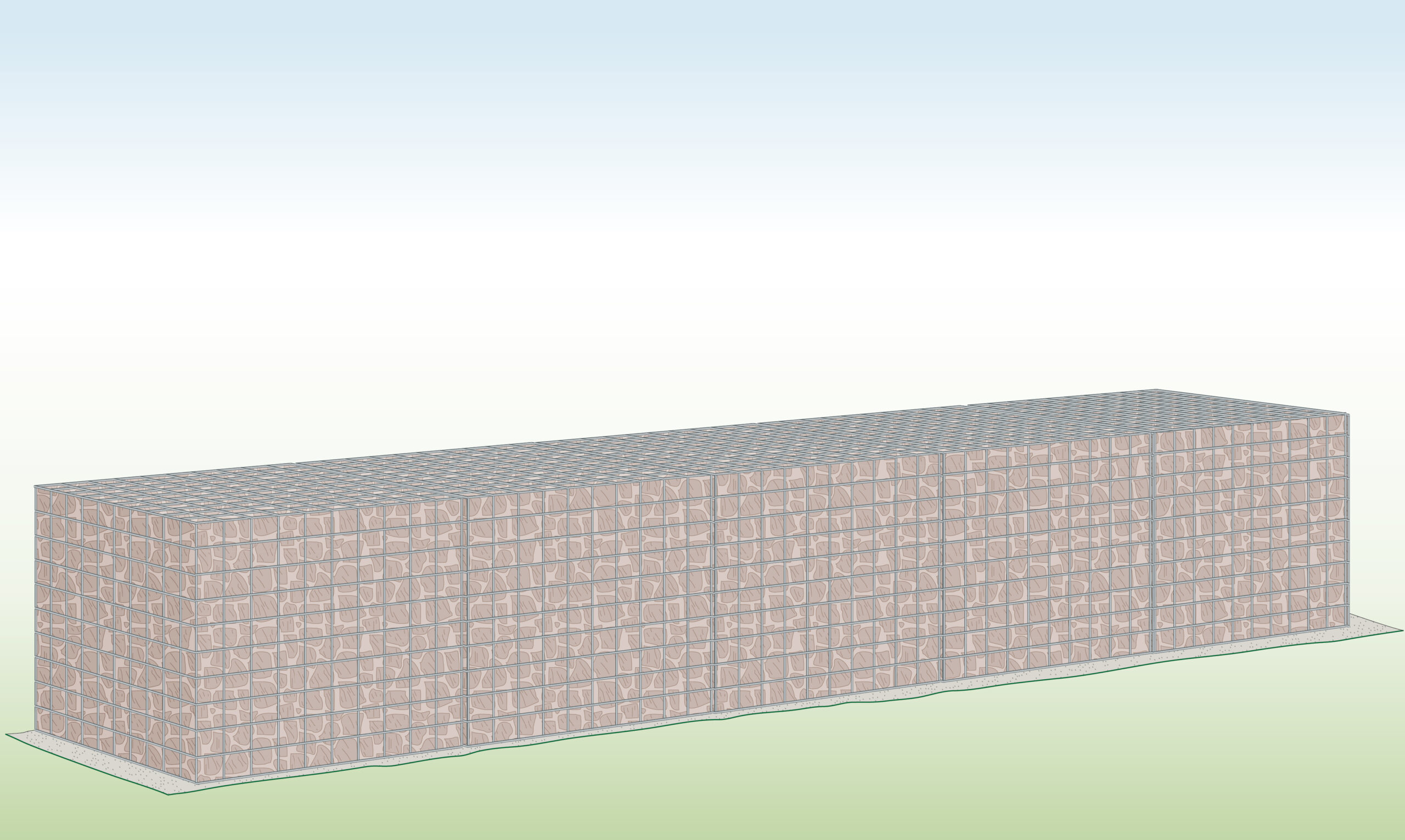

| Step 10 – Finished Project

|

Your freestanding gabion wall is now ready! |

Calculate Stone Quantity

- Use the guide below to calculate the amount of stone that you need to fill your gabion wall

- You can use partitions/stone separating panels to reduce the amount of decorative rocks required by at least half

- You can also save money by filling the middle using rubble bags

| Gabion Wall Dimensions (cm) | Bulk Bags of Stone Required | Bulk Bags of Stone Required if using Partitions | ||

| 97.5cm | 22.5cm | 45cm | 1 | – |

| 195cm | 22.5cm | 45cm | 1 | – |

| 292.5cm | 22.5cm | 45cm | 1 | – |

| 390cm | 22.5cm | 45cm | 1 | – |

| 487.5cm | 22.5cm | 45cm | 1 | – |

| 97.5cm | 45cm | 45cm | 1 | 1 |

| 195cm | 45cm | 45cm | 1 | 1 |

| 292.5cm | 45cm | 45cm | 2 | 1 |

| 390cm | 45cm | 45cm | 2 | 1 |

| 487.5cm | 45cm | 45cm | 3 | 2 |

| 97.5cm | 97.5cm | 45cm | 1 | 1 |

| 195cm | 97.5cm | 45cm | 2 | 1 |

| 292.5cm | 97.5cm | 45cm | 3 | 2 |

| 390cm | 97.5cm | 45cm | 4 | 2 |

| 487.5cm | 97.5cm | 45cm | 5 | 3 |

| 97.5cm | 22.5cm | 97.5cm | 1 | – |

| 195cm | 22.5cm | 97.5cm | 1 | – |

| 292.5cm | 22.5cm | 97.5cm | 2 | – |

| 390cm | 22.5cm | 97.5cm | 2 | – |

| 487.5cm | 22.5cm | 97.5cm | 3 | – |

| 97.5cm | 45cm | 97.5cm | 1 | 1 |

| 195cm | 45cm | 97.5cm | 2 | 1 |

| 292.5cm | 45cm | 97.5cm | 3 | 2 |

| 390cm | 45cm | 97.5cm | 4 | 2 |

| 487.5cm | 45cm | 97.5cm | 5 | 3 |

| 97.5cm | 97.5cm | 97.5cm | 2 | 1 |

| 195cm | 97.5cm | 97.5cm | 4 | 2 |

| 292.5cm | 97.5cm | 97.5cm | 6 | 3 |

| 390cm | 97.5cm | 97.5cm | 8 | 4 |

| 487.5cm | 97.5cm | 97.5cm | 10 | 5 |