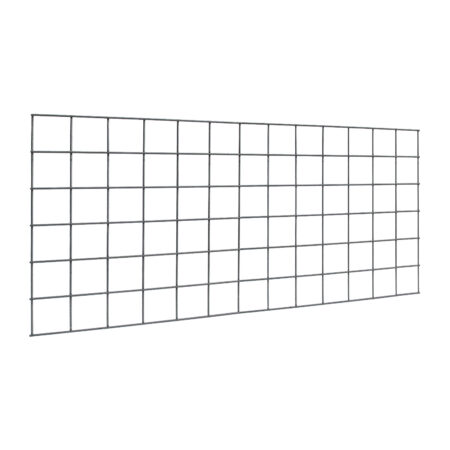

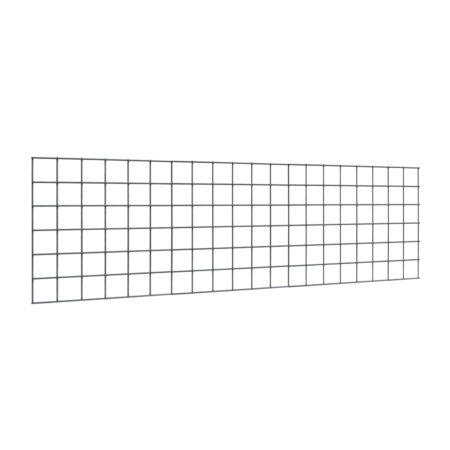

PVC Coated Mesh Panels

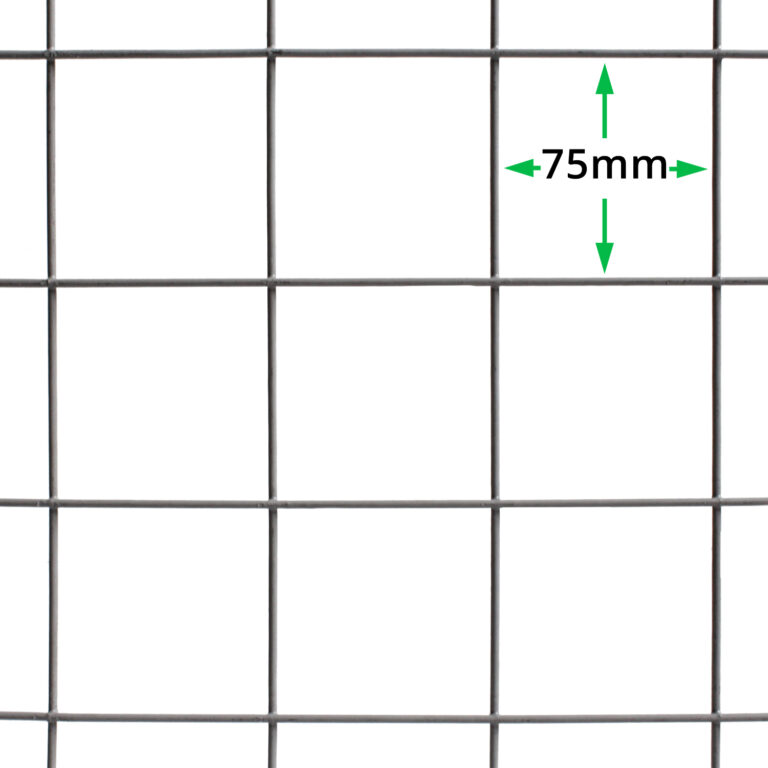

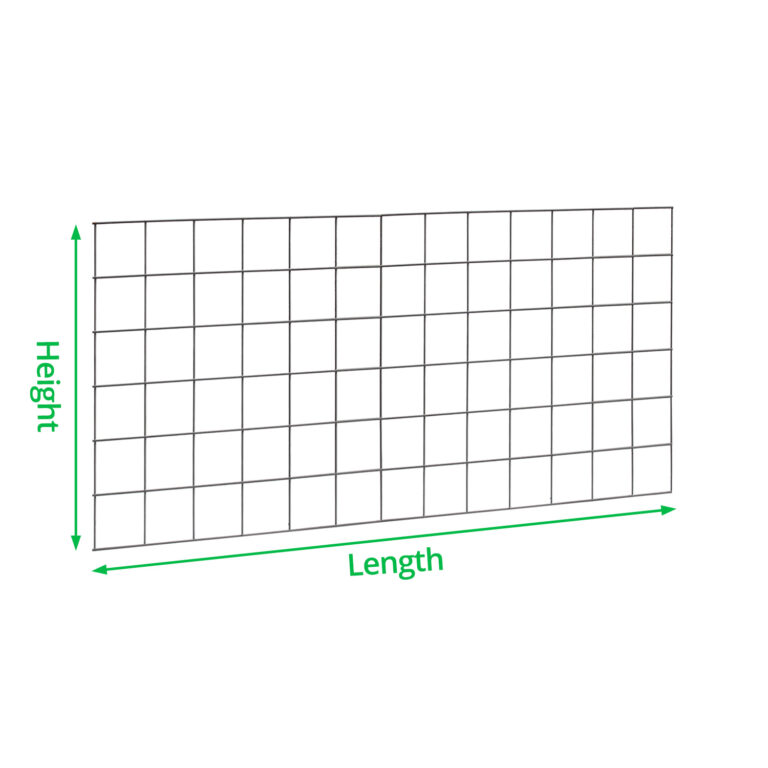

Grey PVC coated welded mesh panels with 75mm x 75mm holes. These panels include a galfan coated steel core making them highly corrosion resistant. Used for multiple applications from security fencing to dog fencing.

We advise you order a minimum quantity of x3 panels to prevent damage during transit.

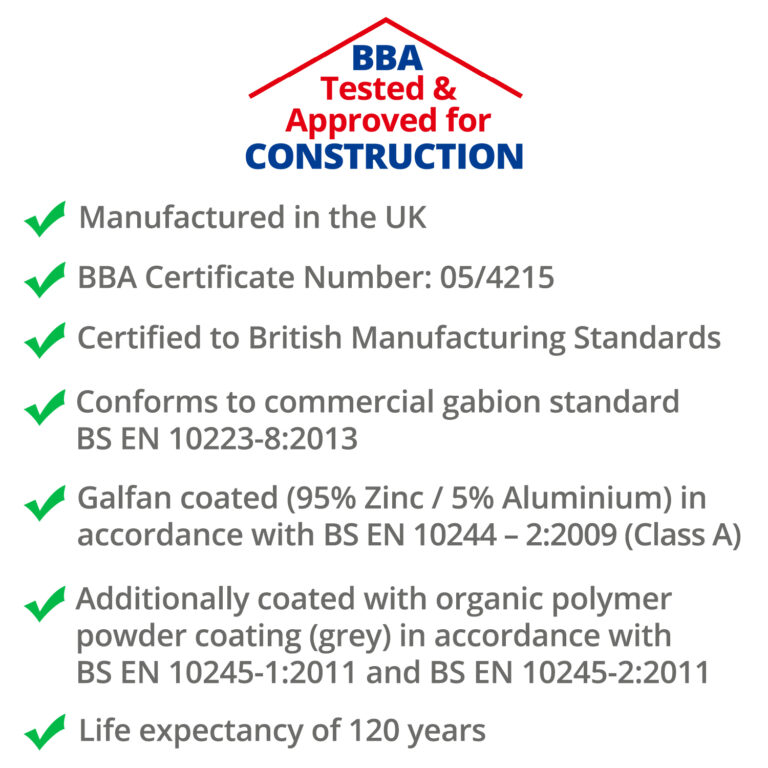

- Manufactured in the UK, to BS EN standards.

- Starting from £4.99

Customer Images

Videos

Recommended applications & uses

| PVC Coated | ||

| 3.2mm Wire Diameter | 4.3mm Wire Diameter | |

| Fencing | ||

| Security fencing | – Security fencing starts at 2.5mm | |

| Perimeter fencing | – for commercial uses we suggest 5mm thick wire | |

| Garden fencing | ||

| Animal enclosures | ||

| Dog runs / pens | – traditional dog fencing is 3mm. Suitable for medium to large dogs | |

| Zoo / large animal enclosures | ||

| Deer Fencing | ||

| Chicken coops | – chicken wire holes should be at least 50mm x 50mm | |

| Fox Poofing | – Fox fencing should have 50mm x 50mm holes | |

| Badger Proofing | – Badger mesh should have 50mm x 50mm holes | |

| Rabbit Proofing | – Rabbit mesh should have 31mm x 31mm hole size | |

| Cat runs | – Cat mesh should have 25mm x 25mm hole size | |

| Aviaries | – Aviary mesh should have 13mm x 13mm hole size | |

| Garden and landscaping | ||

| Garden Trellis | ||

| Pond Cover | – although the hole sizes for pond protection vary. Please check the size required first | |

| Handling | ||

| Is it rigid? | ||

| Can it be rolled up? | ||

| General | ||

| Delivered as | Panels are cable tied together then shrink wrapped | |

| Minimum order | We advise you order a minimum quantity of x3 panels to prevent damage during transit. | |

| Can wires be cut | – with a bolt cutter | |

| Made in UK | Yes | |

| Conforms to British manufacturing standard | BS EN 10223-8:2013 | |

| Certificate of conformity | – upon request | |

| Construction | ||

| Mesh Hole Size | 75mm x 75mm | |

| Mesh Material | Galfan coated steel | |

| Mesh Construction | Welded | |

| Strength and environment | ||

| Tensile strength range | 540-770 N/mm² | |

| Corrosion resistance | Yes, conforms to British standard BS EN 10244-2:2009 | |

| Abrasion resistance | Conforms to EN 60229:2008 | |

| Life Expectancy | 120 years | |

| Suited to Environments | C2 – C5 | C2 – C5 |

Installation Instructions

| Attach to: | With: |

| Wooden Posts | Cable ties, Staples |

| Metal Posts | Cable ties, Tying wire |

| Wire Fence | Cable ties, Tying wire |

| Soil | Pegs |

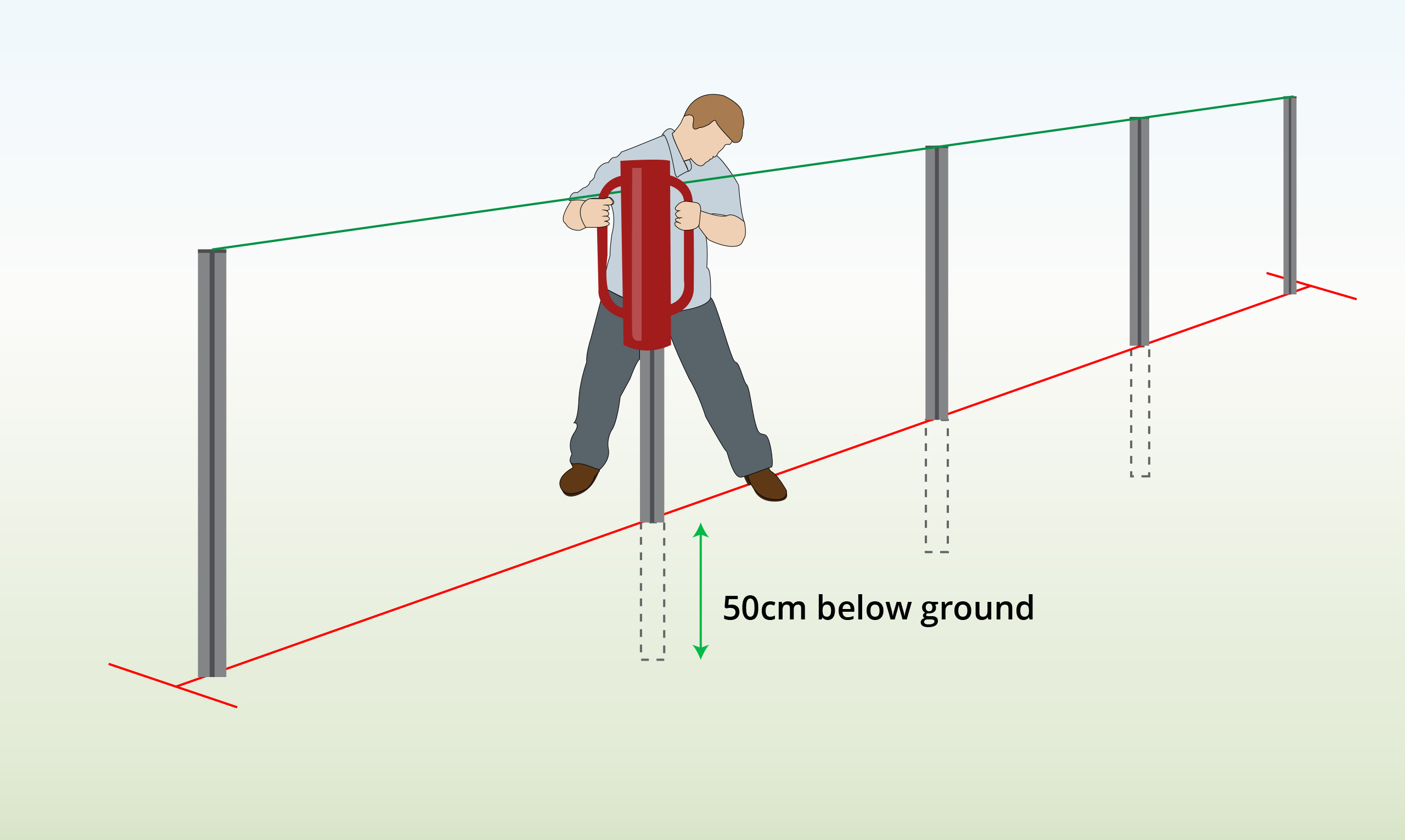

The following instructions show how to install a wire panel fence using T Posts.

| To Do | Explanation |

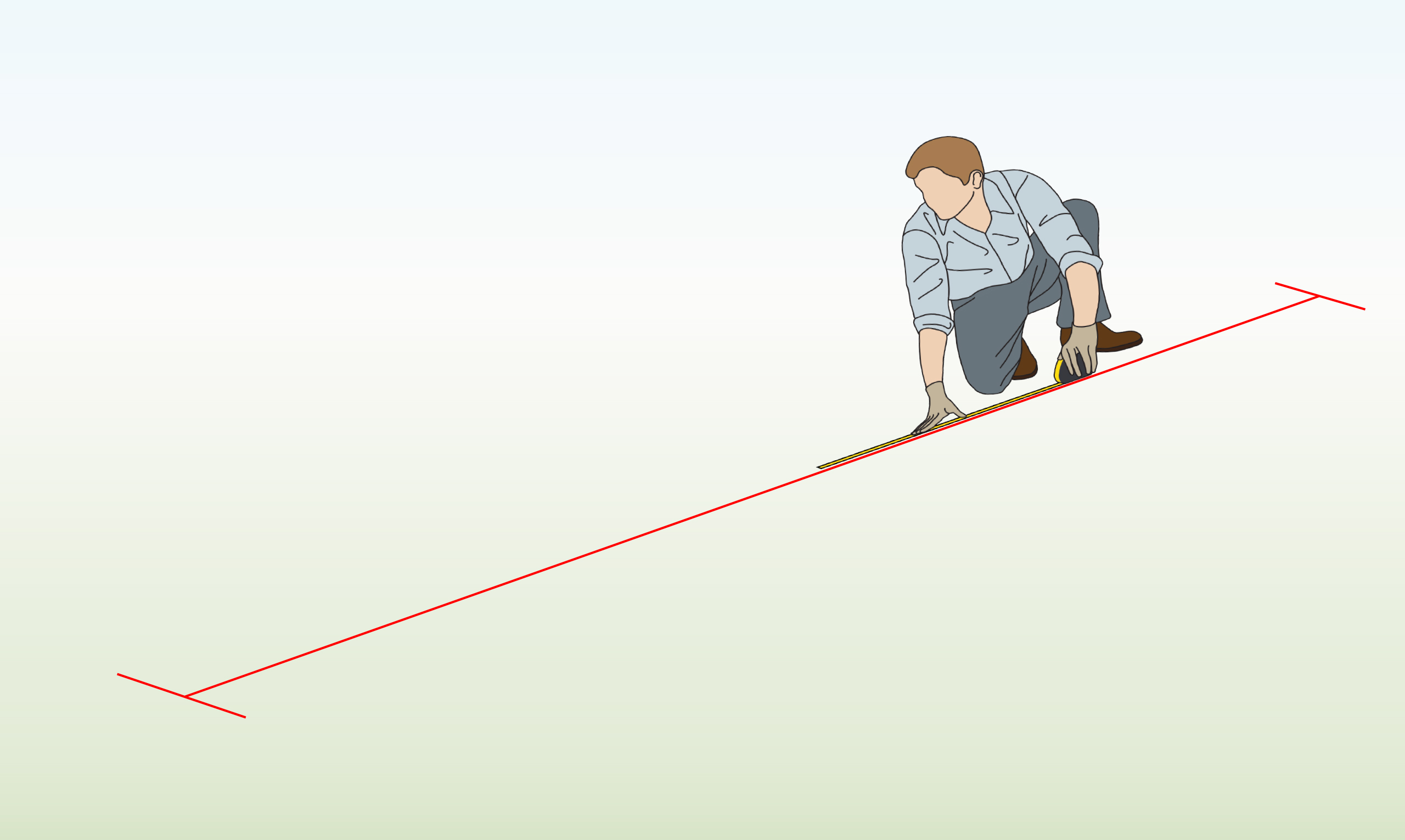

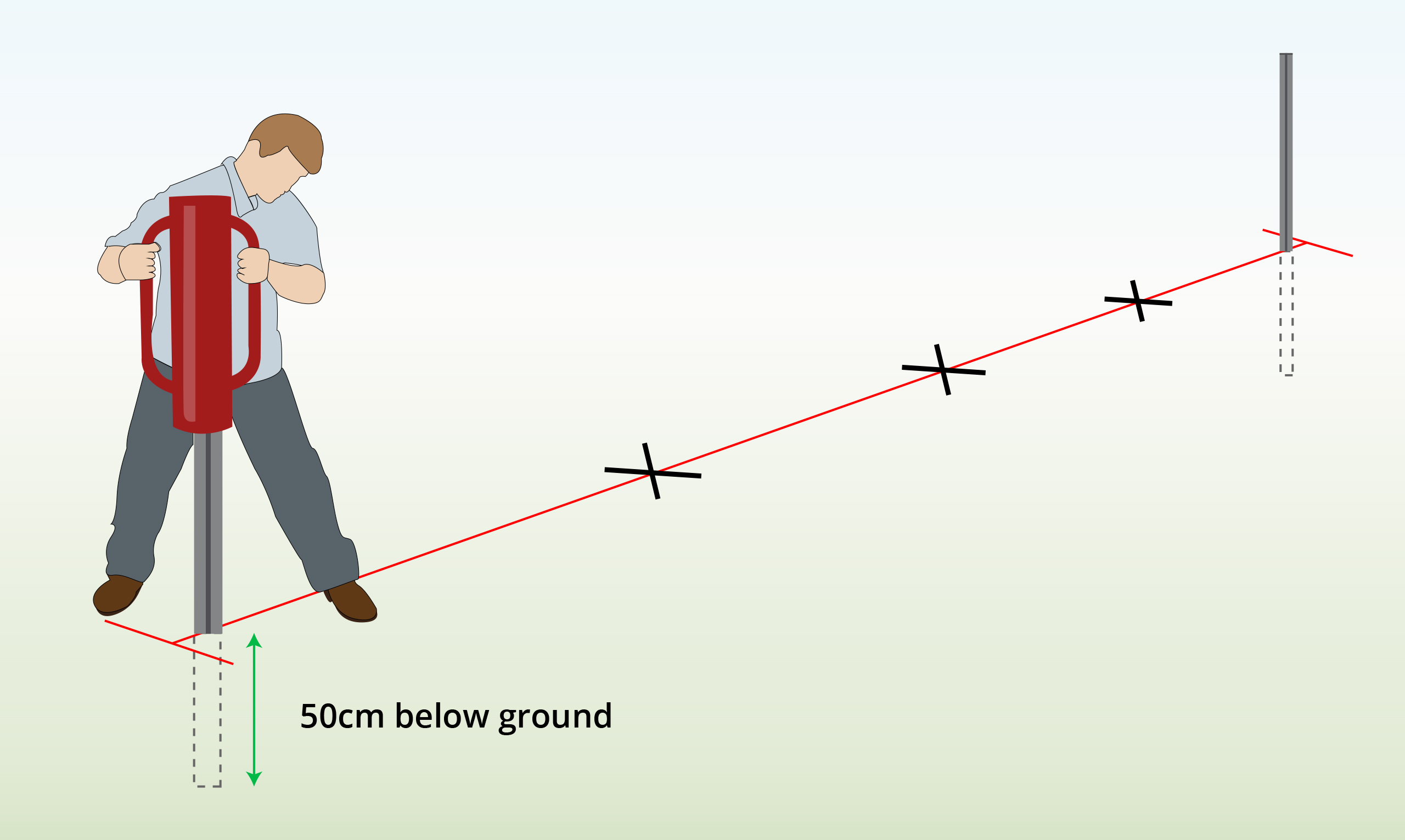

| Step 1 – Mark Area

|

Mark a straight line for the fence between the two end posts. |

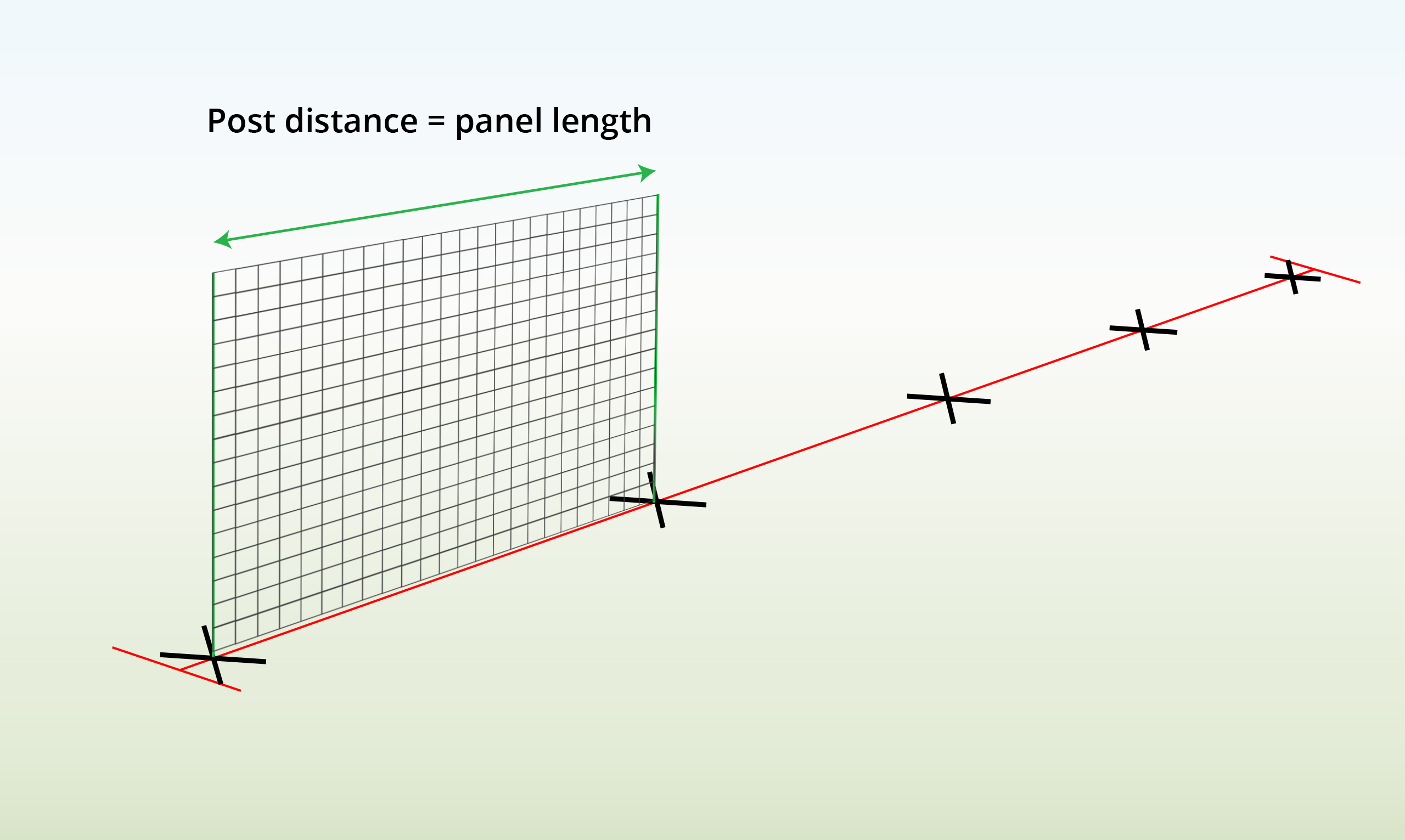

| Step 2 – Measure Distance

|

Use panels to measure the distance between the posts. |

| Step 3 – Install End Posts

|

Drive the end posts 50cm into the ground using a post driver or mallet.

Ensure the posts face in the same direction. |

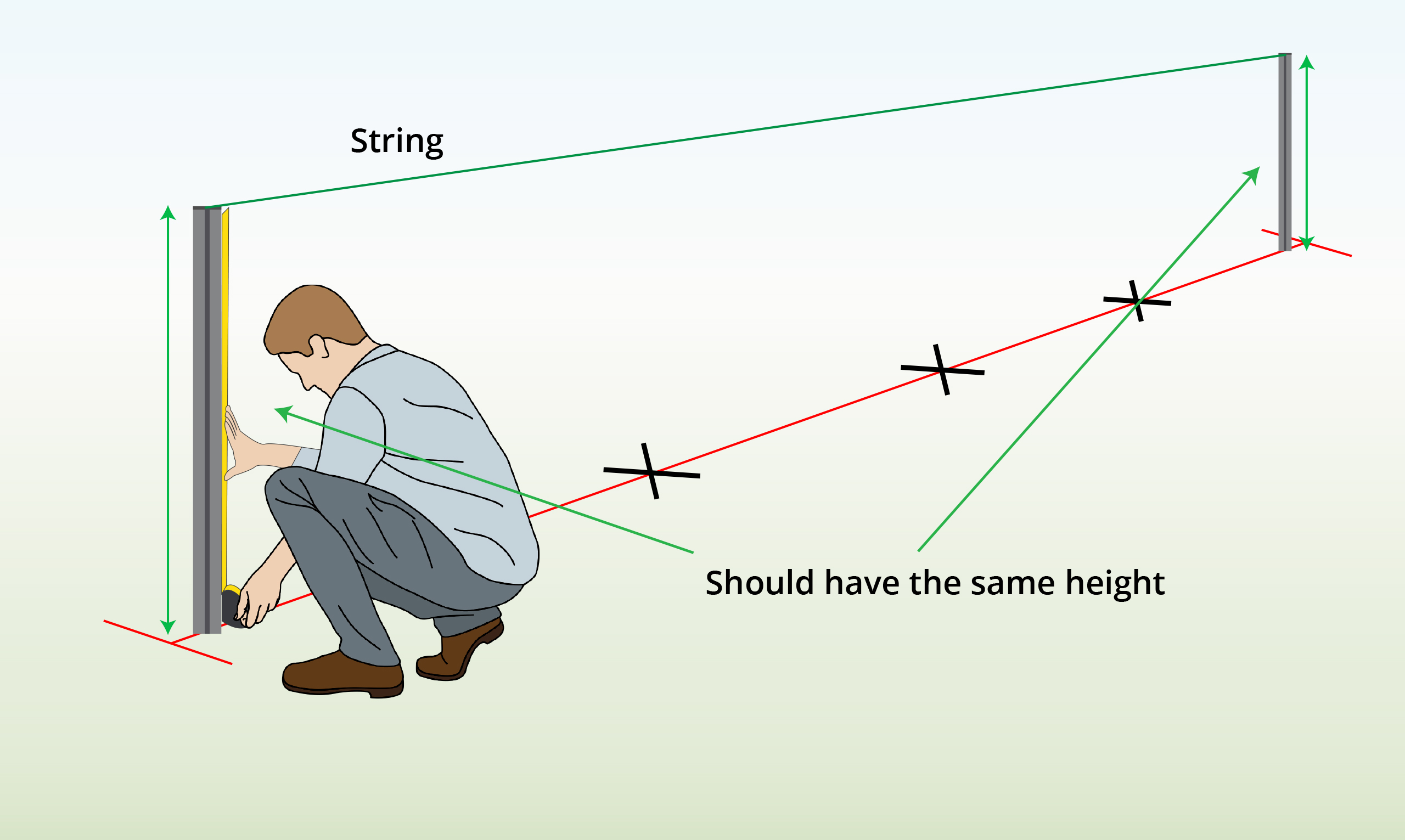

| Step 4 – Check for Same Height

|

Secure a string between the end posts, then check their installation height with a tape measure. |

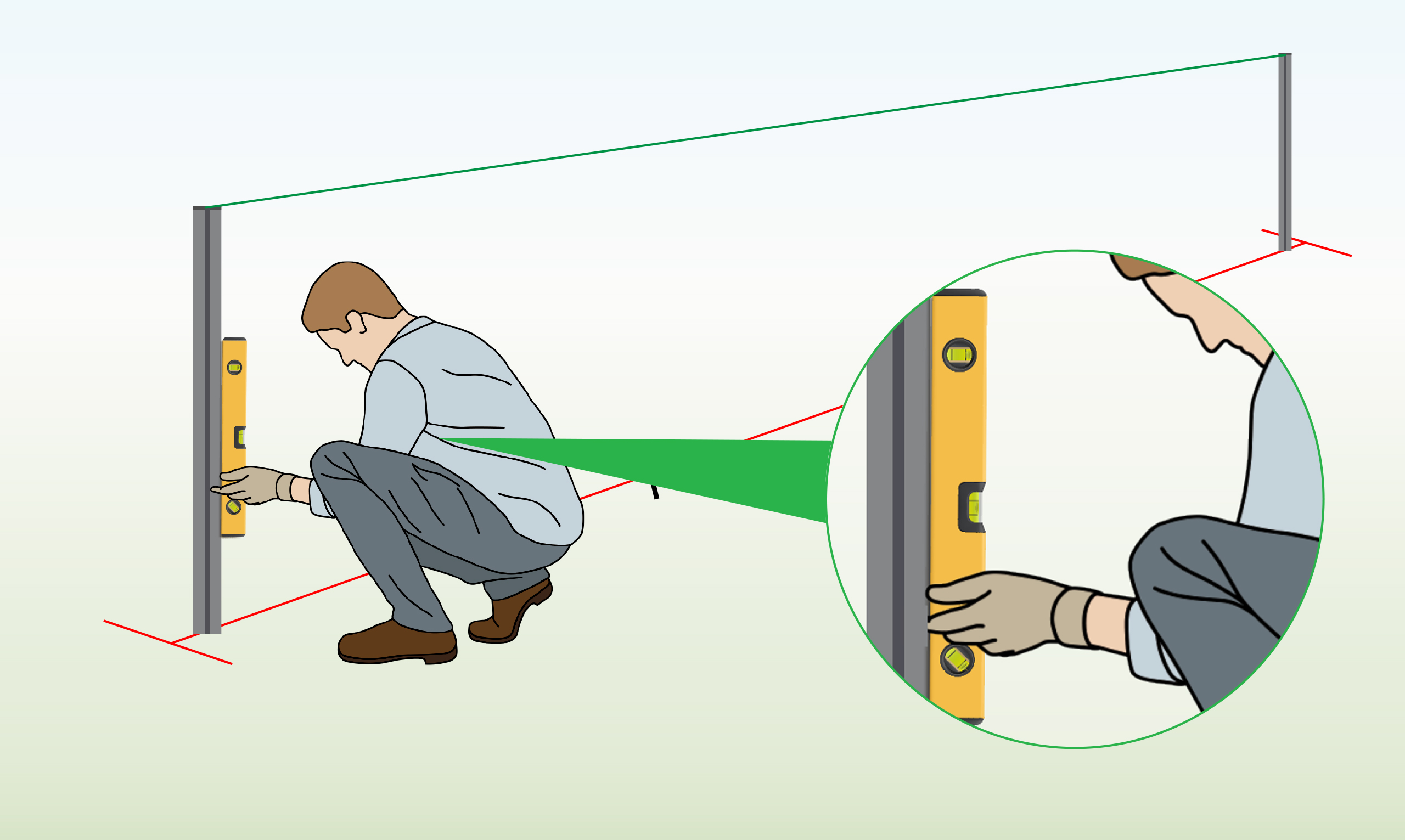

| Step 5 – Check for Straightness

|

Use a spirit level to confirm that the posts have been installed perfectly straight. |

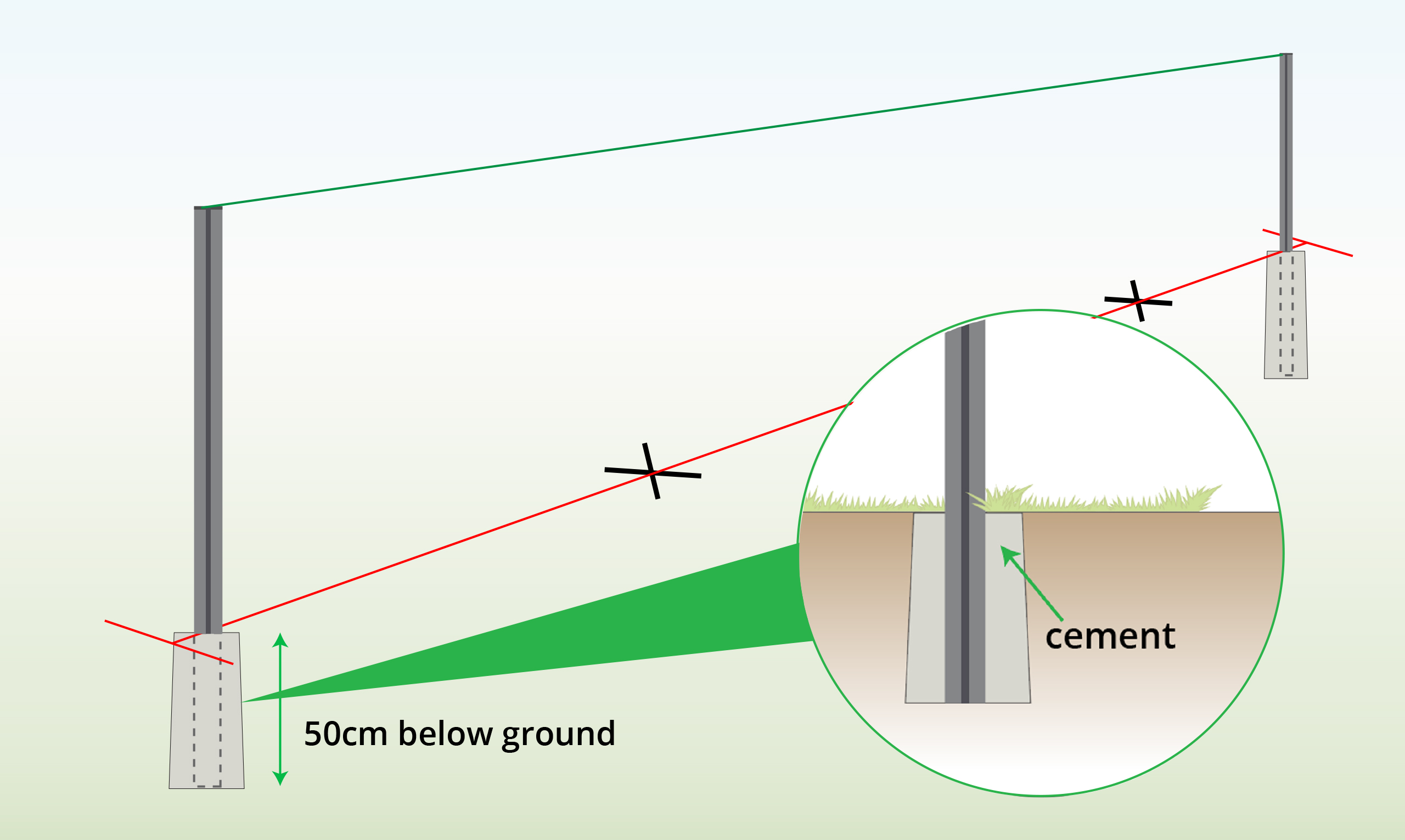

| Step 6 (Optional) – Set in Concrete

|

To achieve a stronger and more secure fence, place your posts in concrete by digging a 50cm hole and pouring cement into it for your post to sit in. |

| Step 7 – Install Middle Posts

|

To install middle posts, repeat steps 3-5.

|

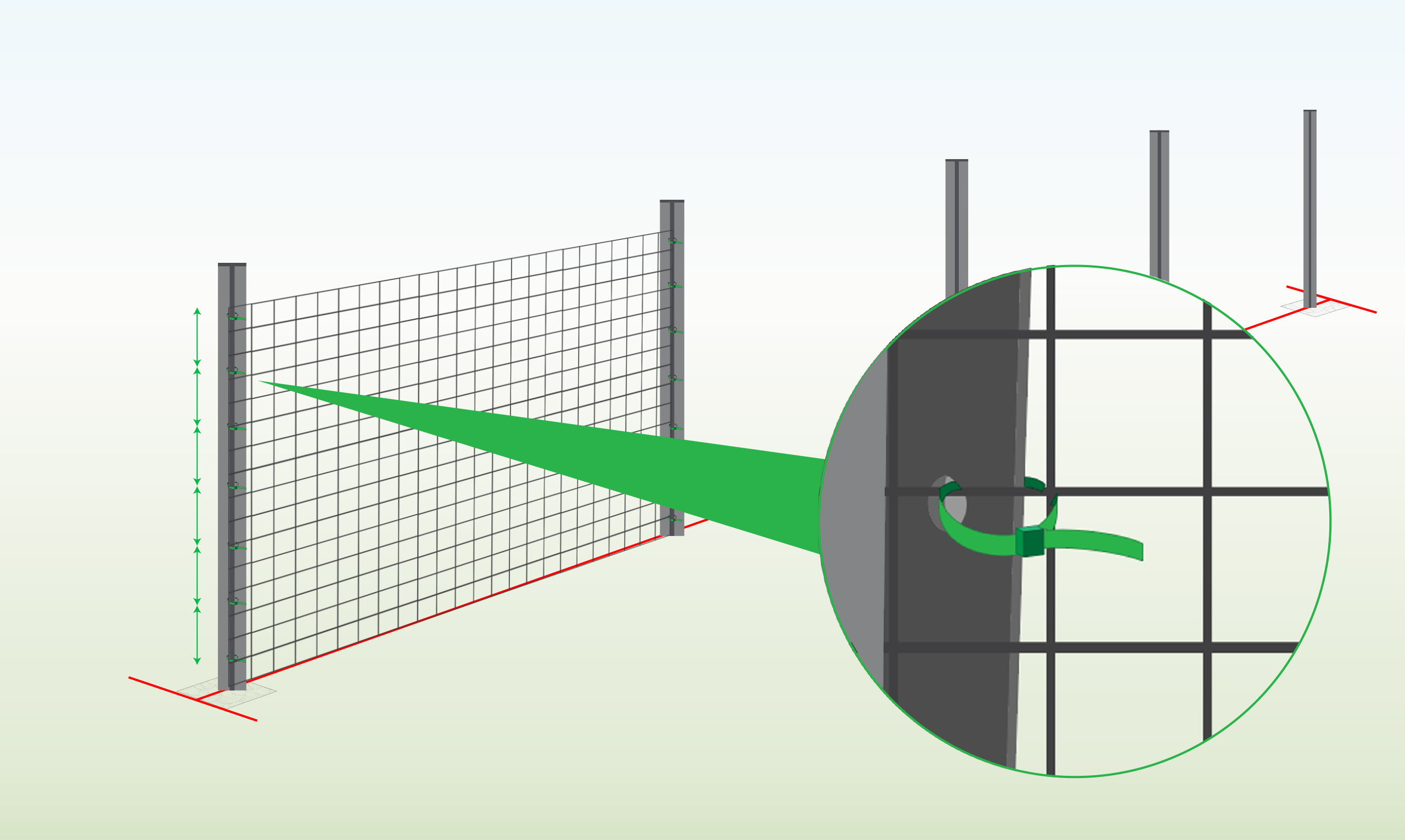

| Step 8 – Attach Panels

|

Begin at the end post and fasten the mesh to it using cable ties, which can be threaded through the pre-drilled holes in the post.

You can add additional cable ties by enclosing the entire post. |

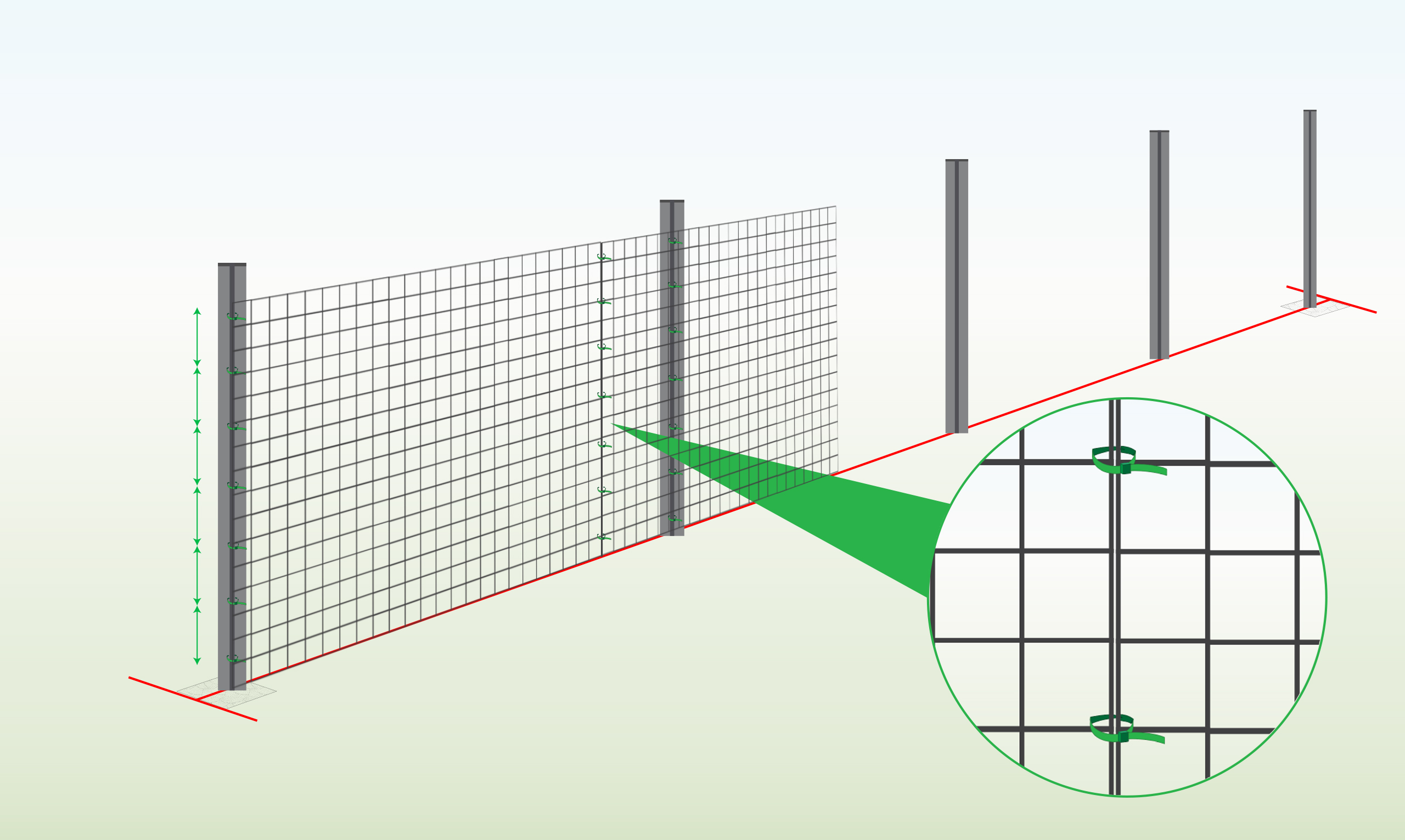

| Alternative Option

|

Increase the spacing between the posts by overlapping the panels. Connect them by securing them together with cable ties. |