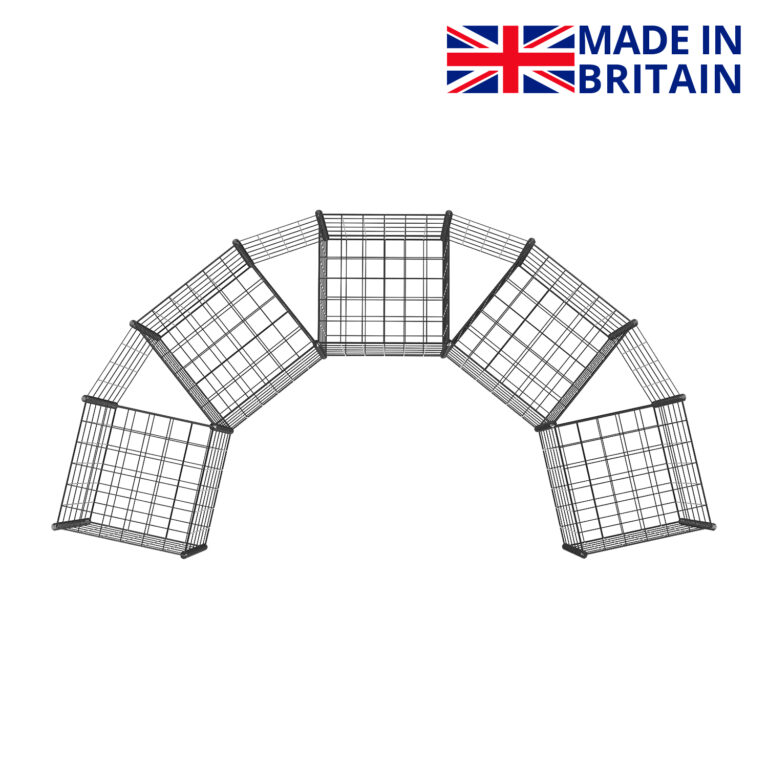

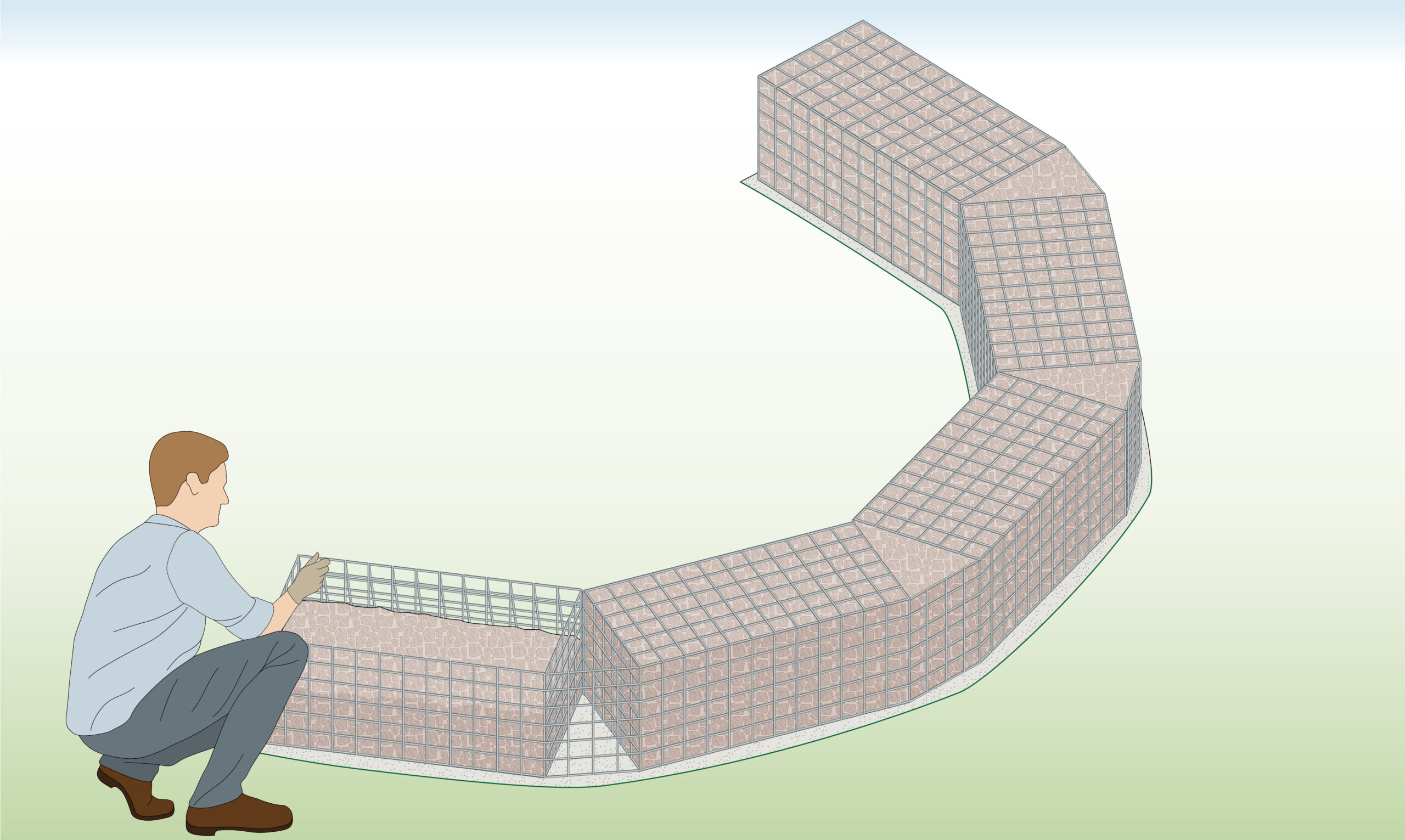

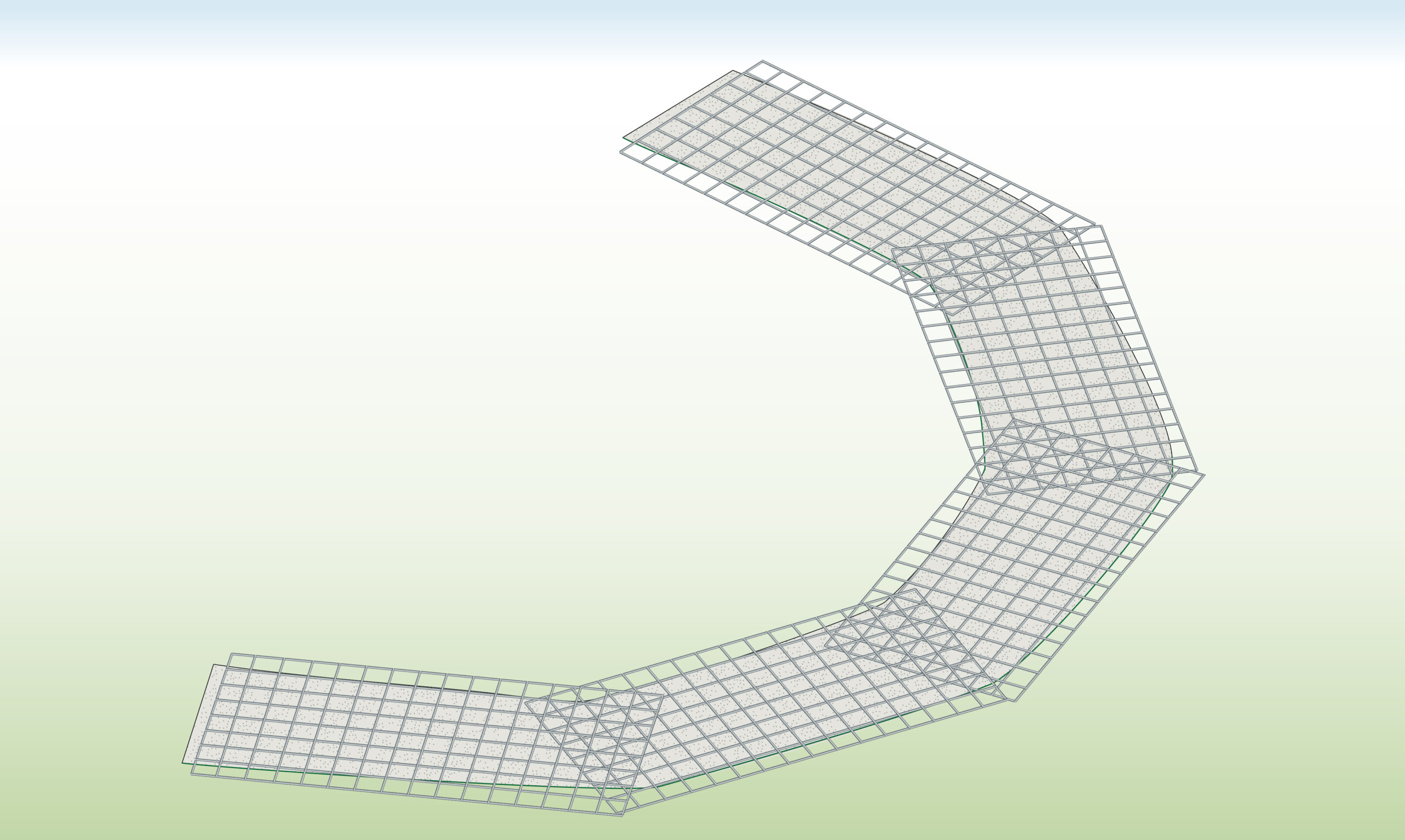

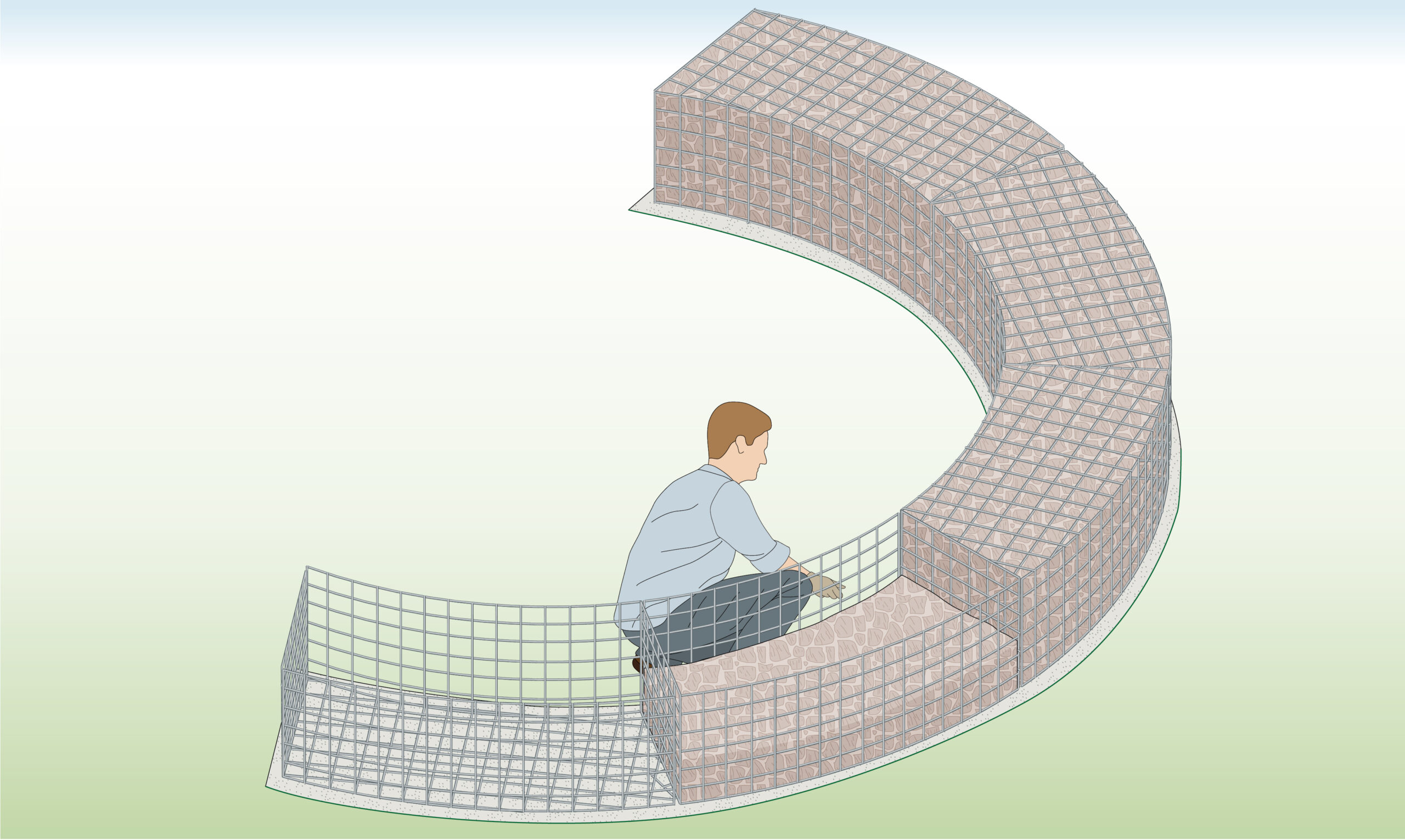

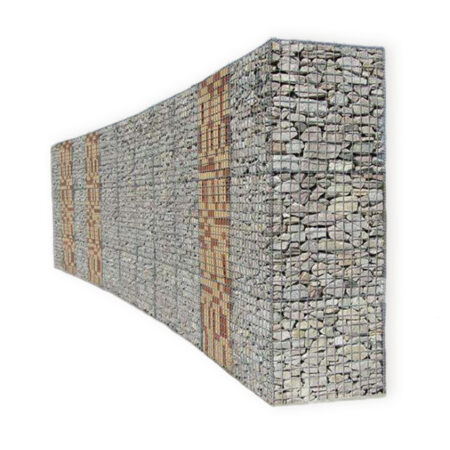

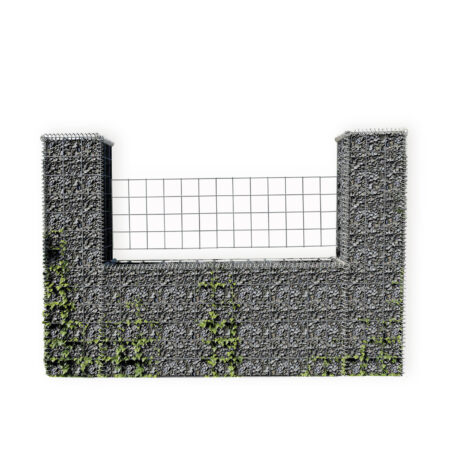

Curved Gabions

Easily create curved gabion baskets using our simple-to-follow instructions. Commonly used to make curved gabion walls, benches and planters.

- Manufactured in the UK, to BS EN standards.

- Next day delivery options

Customer Images

Videos

Recommended applications & uses

| Galfan Coated | PVC Coated | ||||

| 3mm Wire Diameter | 4mm Wire Diameter | 5mm Wire Diameter | 3.2mm Wire Diameter | 4.3mm Wire Diameter | |

| Curved gabion | |||||

| Can be walked on | |||||

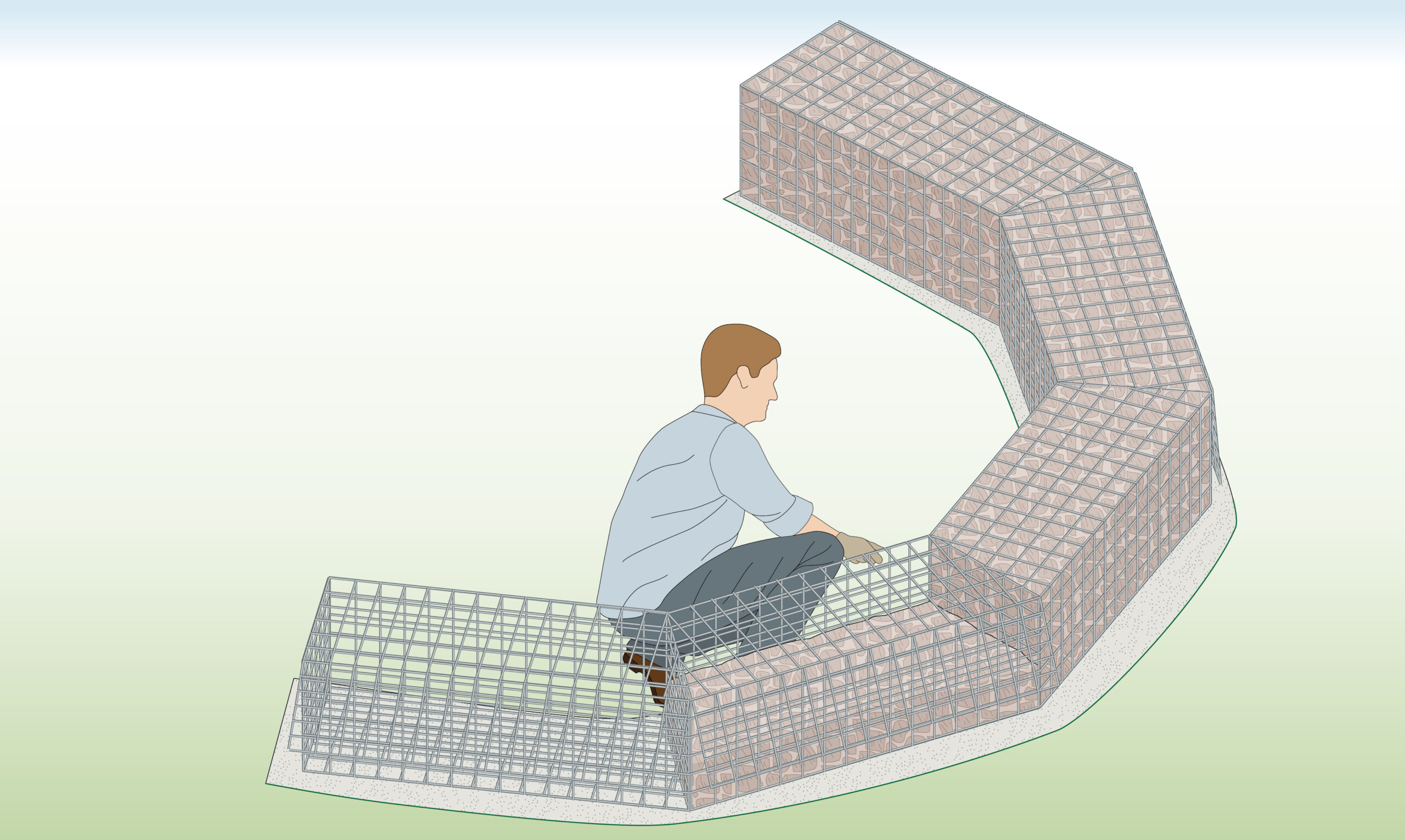

| Can be sat on | |||||

| Tall or thin structures | |||||

| Planters | |||||

| Freestanding structure | |||||

| Retaining structure (up to 5m) | |||||

| Retaining structure (5m and over) | |||||

| Erosion control | |||||

| Coastal protection | |||||

| Landscaping: no bulges when filled with irregularly shaped rocks | |||||

| Landscaping: no bulges when filled with rounded rocks | |||||

| Public leisure areas | |||||

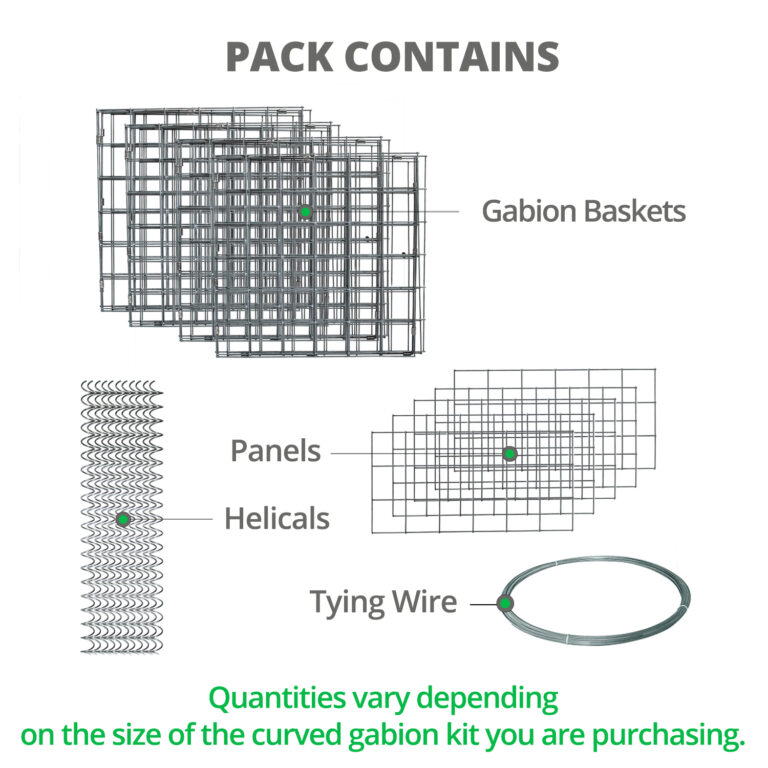

| Delivered as | Flat packed in small to large truck depending on order quantity | ||||

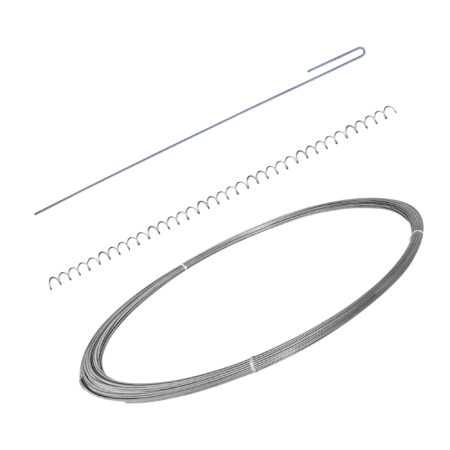

| Delivered with | Delivered with FREE tying wire | ||||

| Also available | Helicals for quicker assembly of the 4 vertical corners (ordered separately) | ||||

| Also available | Corner ties to prevent bulging (ordered separately) | ||||

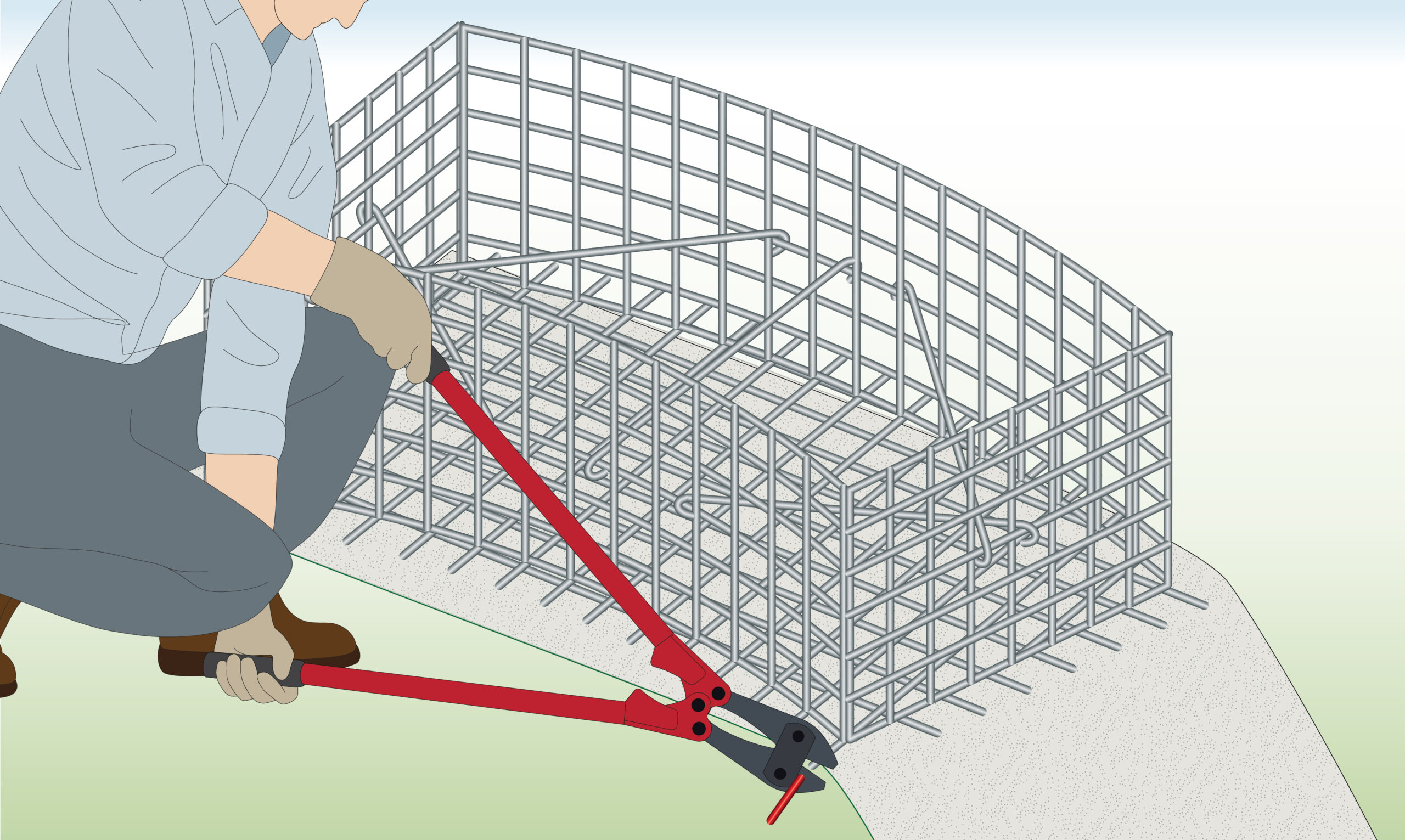

| Can wires be cut | Yes – with bolt cutters | ||||

| Made in UK | Yes | ||||

| Conforms to British manufacturing standard | BS EN 10223-8:2013 | ||||

| Certificate of conformity | Yes – download | ||||

| Construction | |||||

| Mesh Hole Size | 75mm x 75mm | 75mm x 75mm | 75mm x 75mm | 75mm x 75mm | 75mm x 75mm |

| Mesh Material | Galfan coated steel | Galfan coated steel | Galfan coated steel | Galfan coated steel with PVC coating | Galfan coated steel with PVC coating |

| Mesh Construction | Welded | Welded | Welded | Welded | Welded |

| Mesh panels joined together by | Stainless steel C Clips | ||||

| Strength and environment | |||||

| Tensile strength range | 540-770 N/mm² | 540-770 N/mm² | 540-770 N/mm² | 540-770 N/mm² | 540-770 N/mm² |

| Corrosion resistance | Yes, conforms to British standard BS EN 10244-2:2009 | ||||

| Abrasion resistance | Conforms to EN 60229:2008 | ||||

| Life Expectancy | 50 – 100 years | 50 – 100 years | 50 – 100 years | 120 years |

120 years |

| Suited to Environments | C2 – C4 | C2 – C4 | C2 – C4 | C2 – C5 | C2 – C5 |

| Rocks / Filling / Installation | |||||

| Speed of installation | 2-5 mins each | ||||

| Experience required to install | Easy install | ||||

| Depth of structure | Minimum half of the height | ||||

| Rock size required | Minimum 80mm x 80mm | ||||

| Requires angular, interlocking rocks | |||||

| Can be filled with crushed concrete | |||||

| Can fill with rounded rocks | |||||

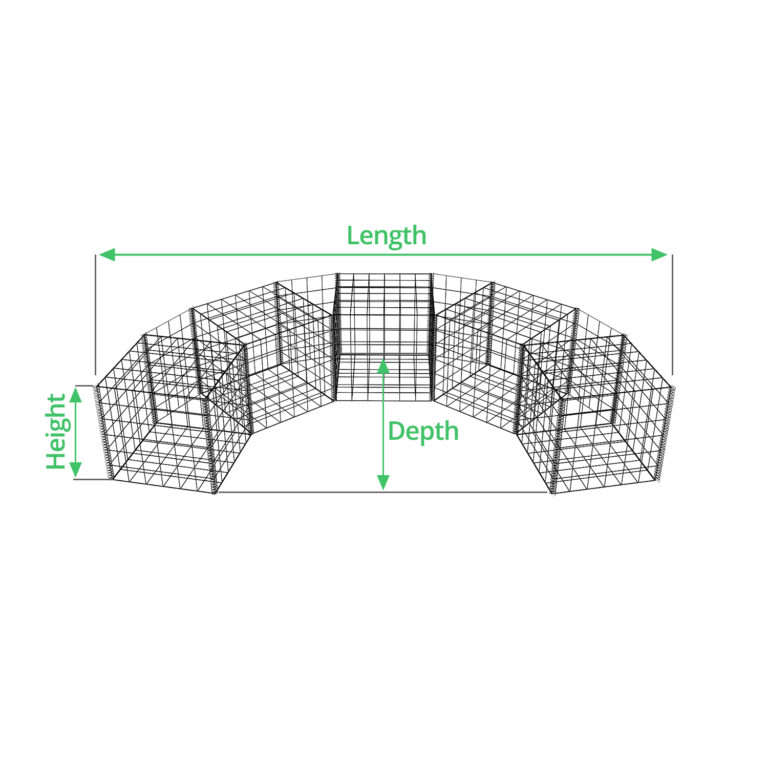

Measuring Instructions

Use the following instructions to measure exactly how many baskets you need before placing your order.

| Explanation | |

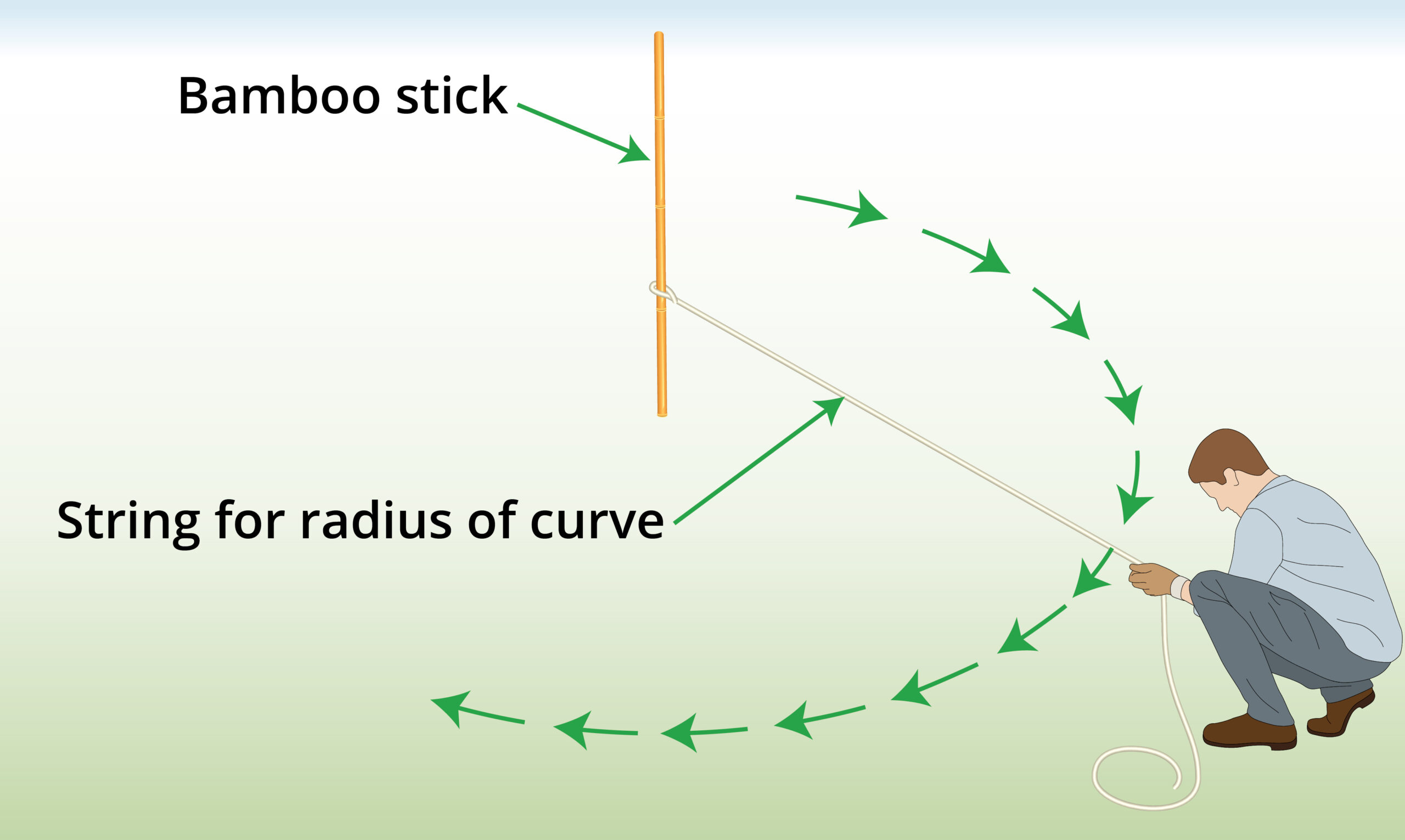

| Step 1 – Walk the curve

|

Attach string to a bamboo stick. Pull the string taut, then walk the string along the area where you would like to create a curved gabion wall. |

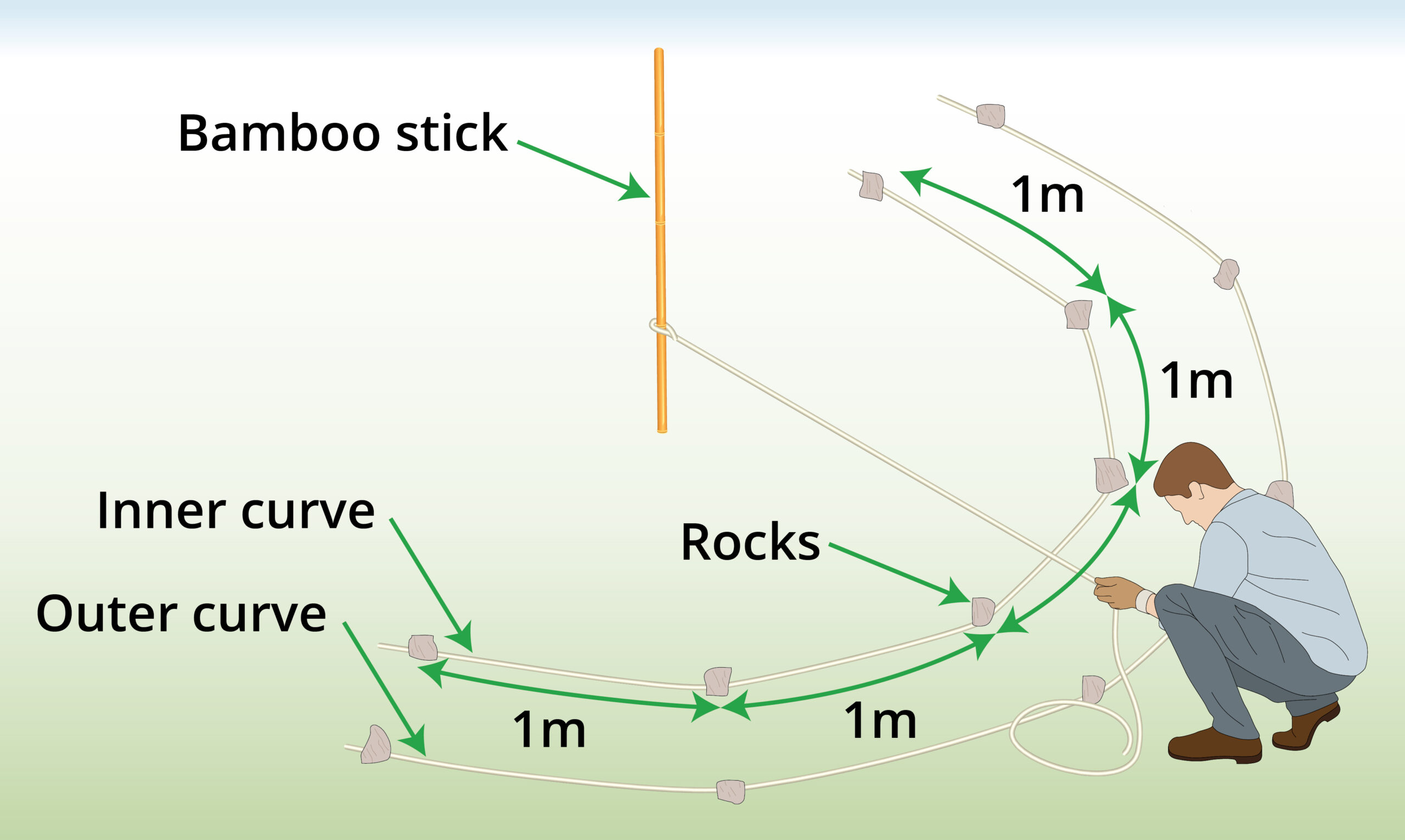

| Step 2 – Mark the curve using string

|

Place string along the curve where you plan to install the wall. The string should be placed on the ground and used to mark the inner and outer sides. Hold the string in place at every 1 meter distance using rocks. |

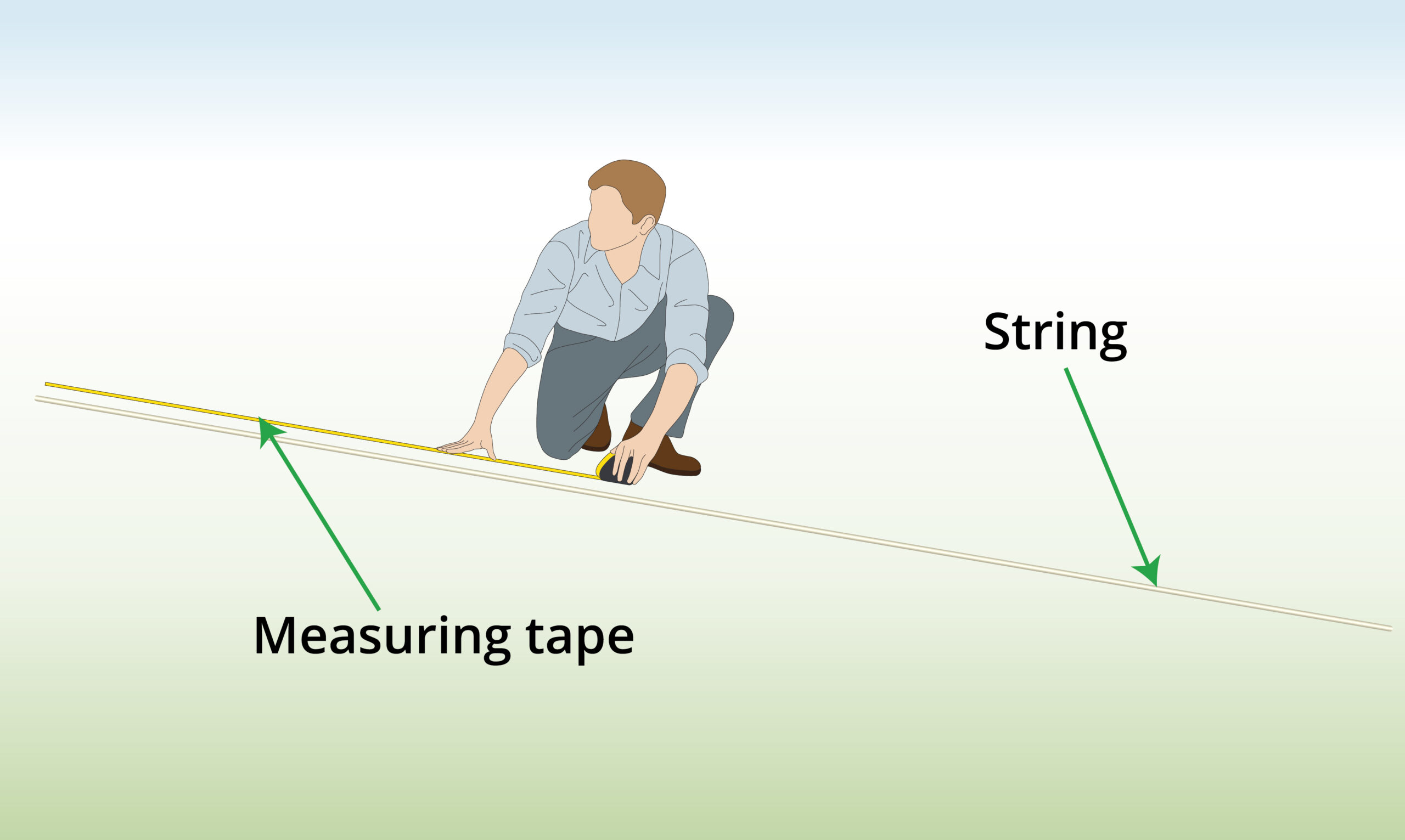

| Step 3 – Measure the string

|

Lay the string on the ground, then use a measuring tape to record the length of both pieces of string. |

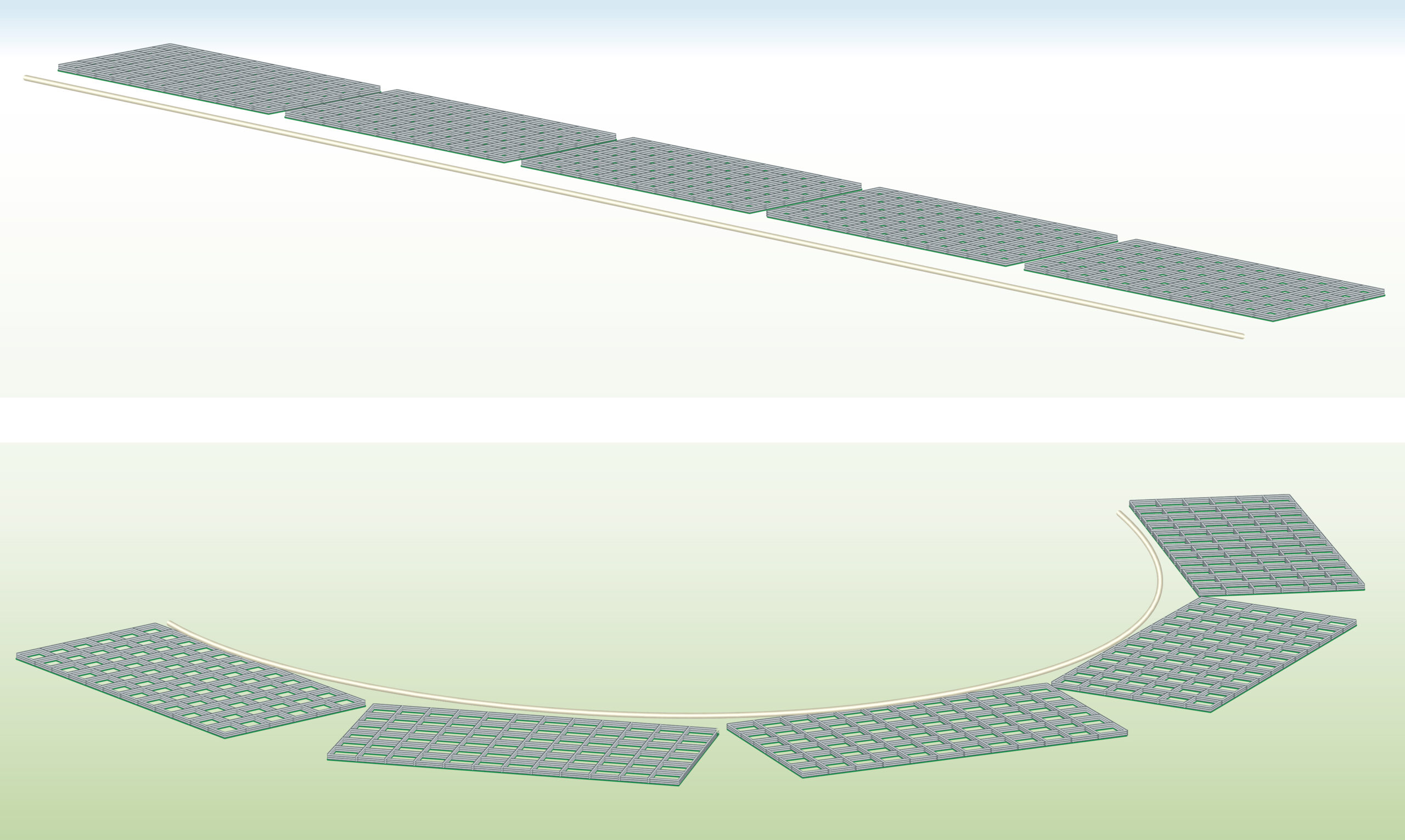

| Step 4 – Order materials

|

You will need enough cages to cover the length of your inner curve.

45cm or 97.5 cm cages will give you the best curve effect. Longer cages can also be used but the curve effect will not be as pronounced. |

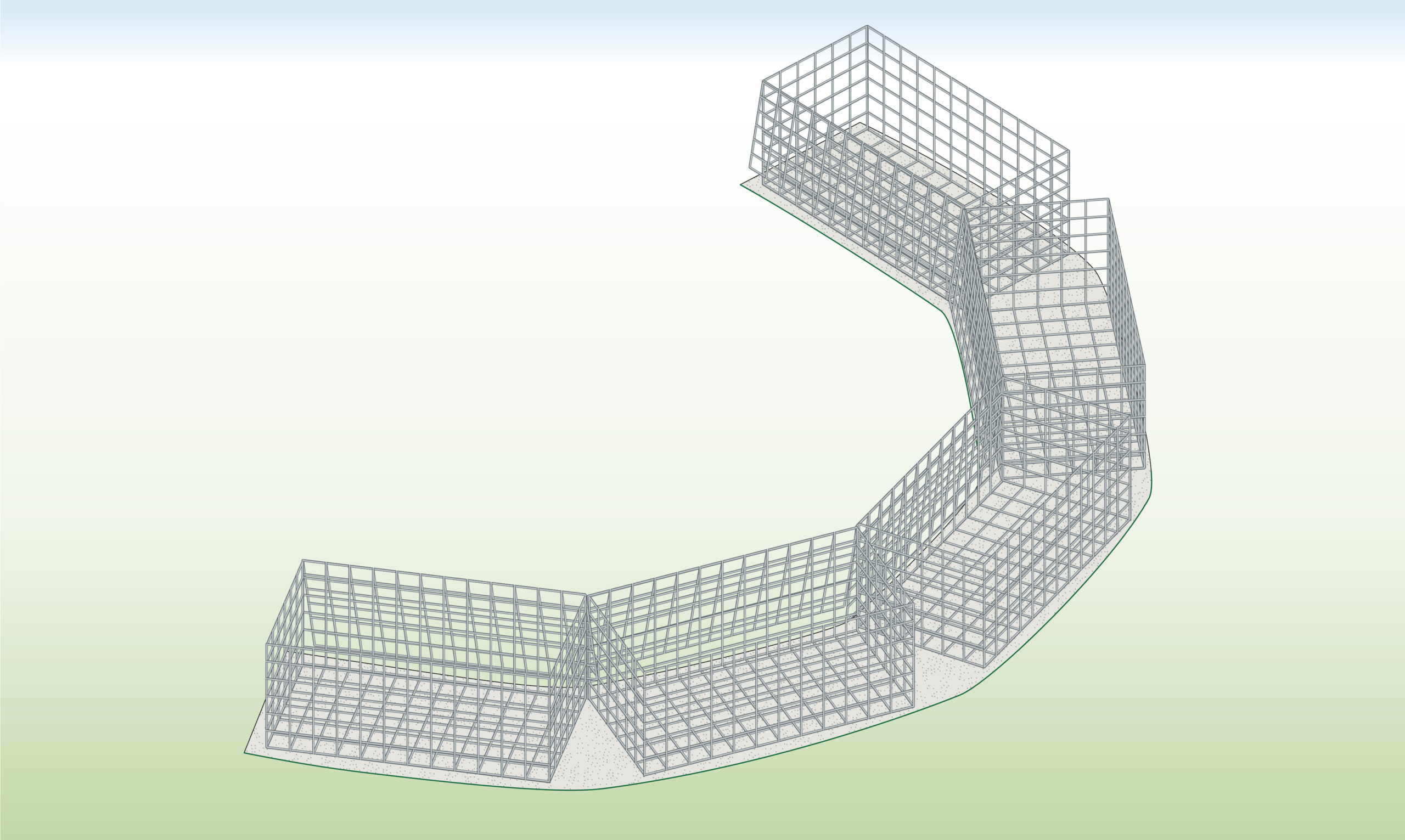

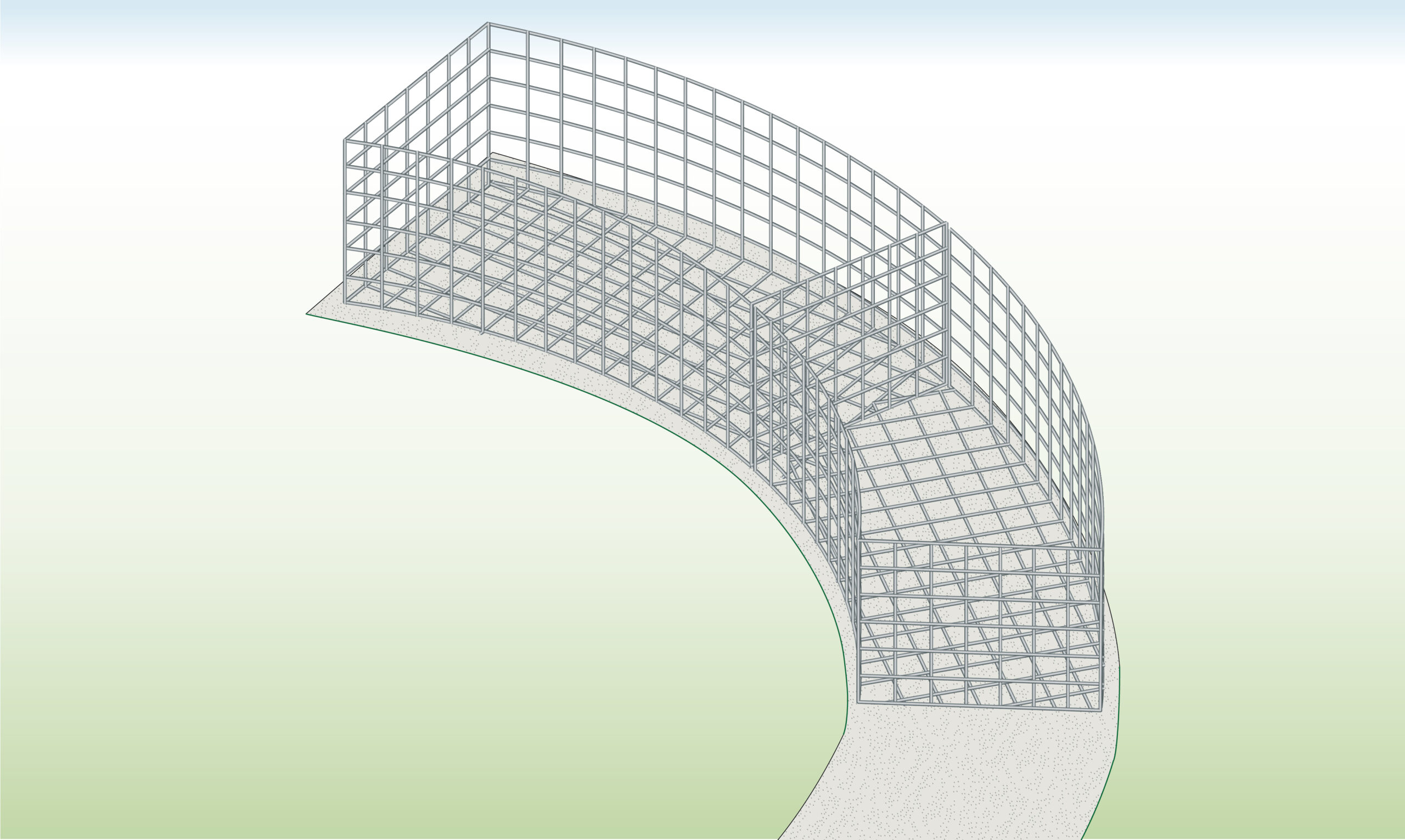

Installation Instructions

-

Kit Installation Easiest to measure, calculate the material required, and install. Sold as a kit with everything you need to construct the curved structure.

-

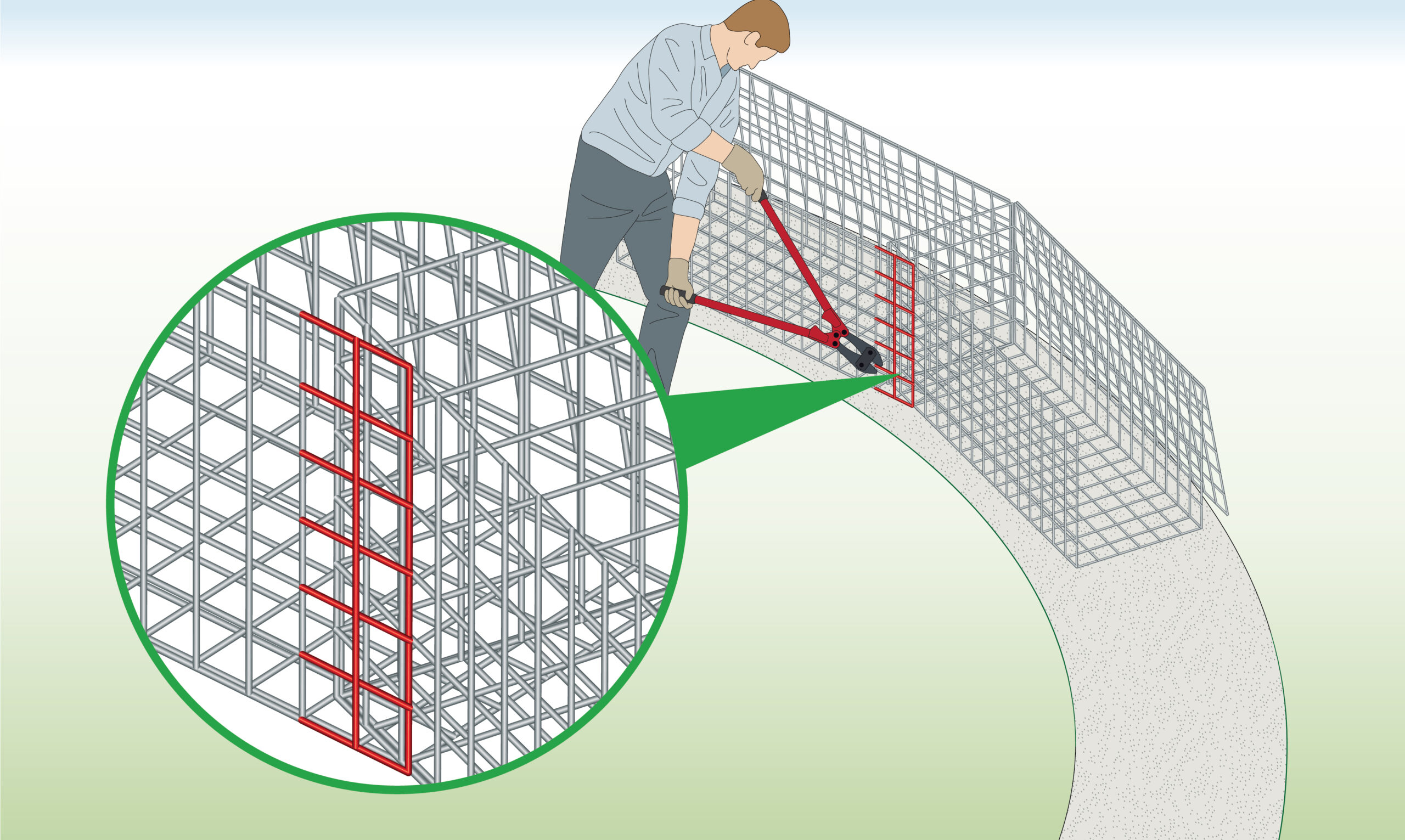

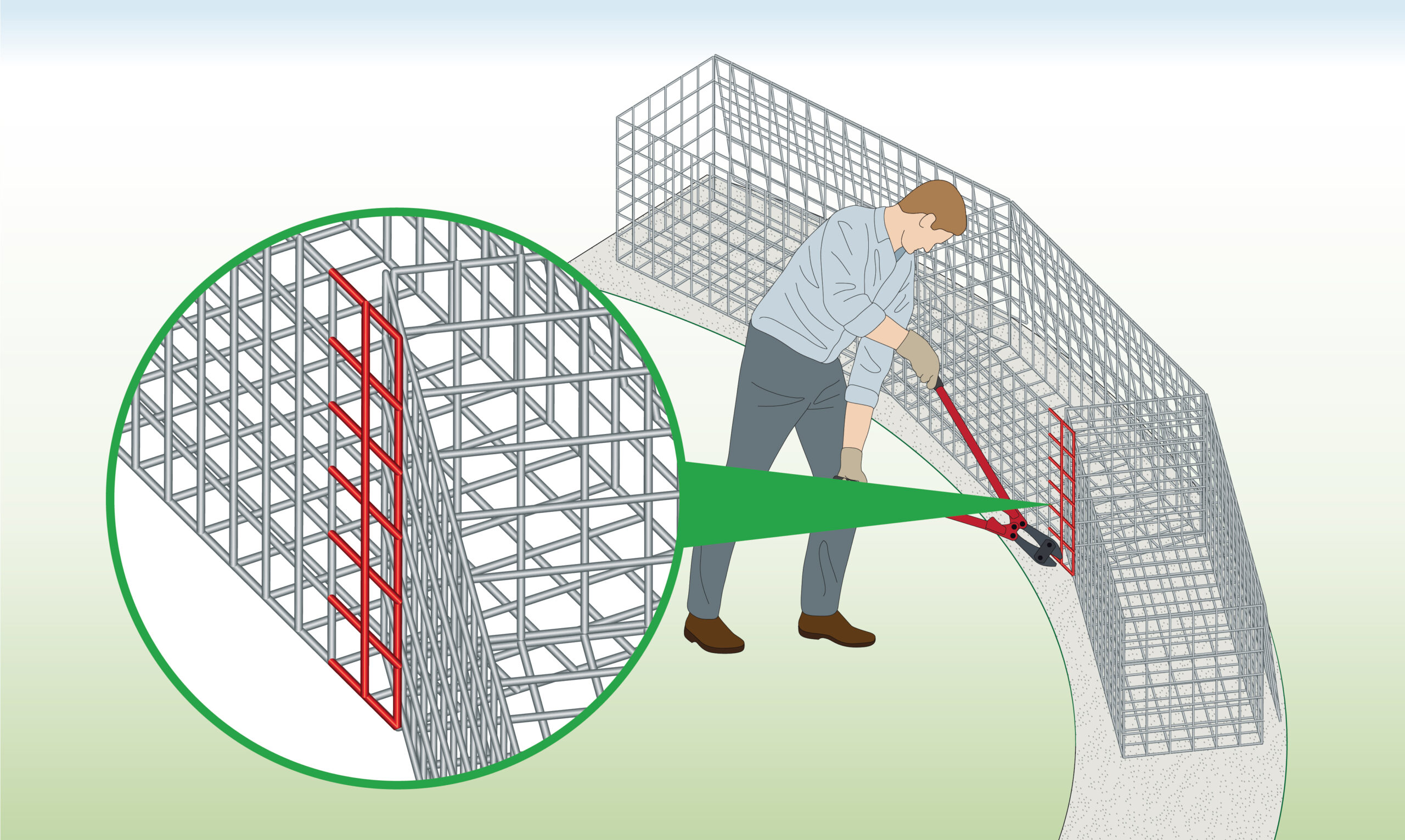

Mitre Corner Installation Offers the most flexibility to adjust the radius of the curve when installing. Requires bolt cutters so you cut openings to create a mitre corner.

-

DIY Installation This installation technique will create an actual rounded edge but installation is longer than other techniques.

| To Do | Explanation |

| Step 1 – Mark Area

|

Mark the area where you plan to install before placing your order.

If possible, keep the area marked until your order arrives to ensure the curve shape remains exactly the same.

It is possible to adjust the shape slightly after delivery but if the curve changes significantly, you may need to reorder new materials. |

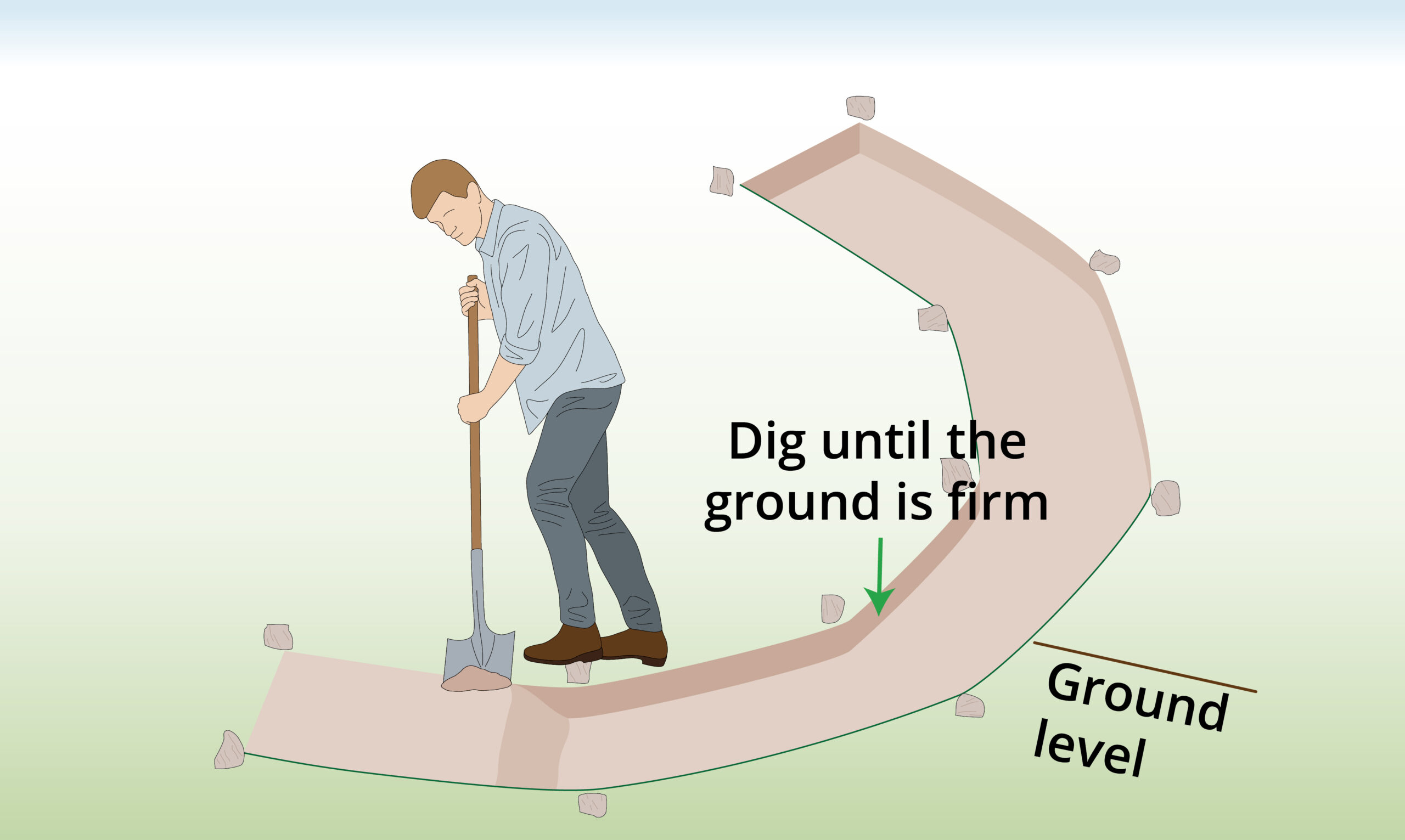

| Step 2 – Dig

|

Dig until the ground is firm. Structures 1m tall or less are often placed directly on the ground but they will be more stable if placed on firm ground such as clay instead of the topsoil. |

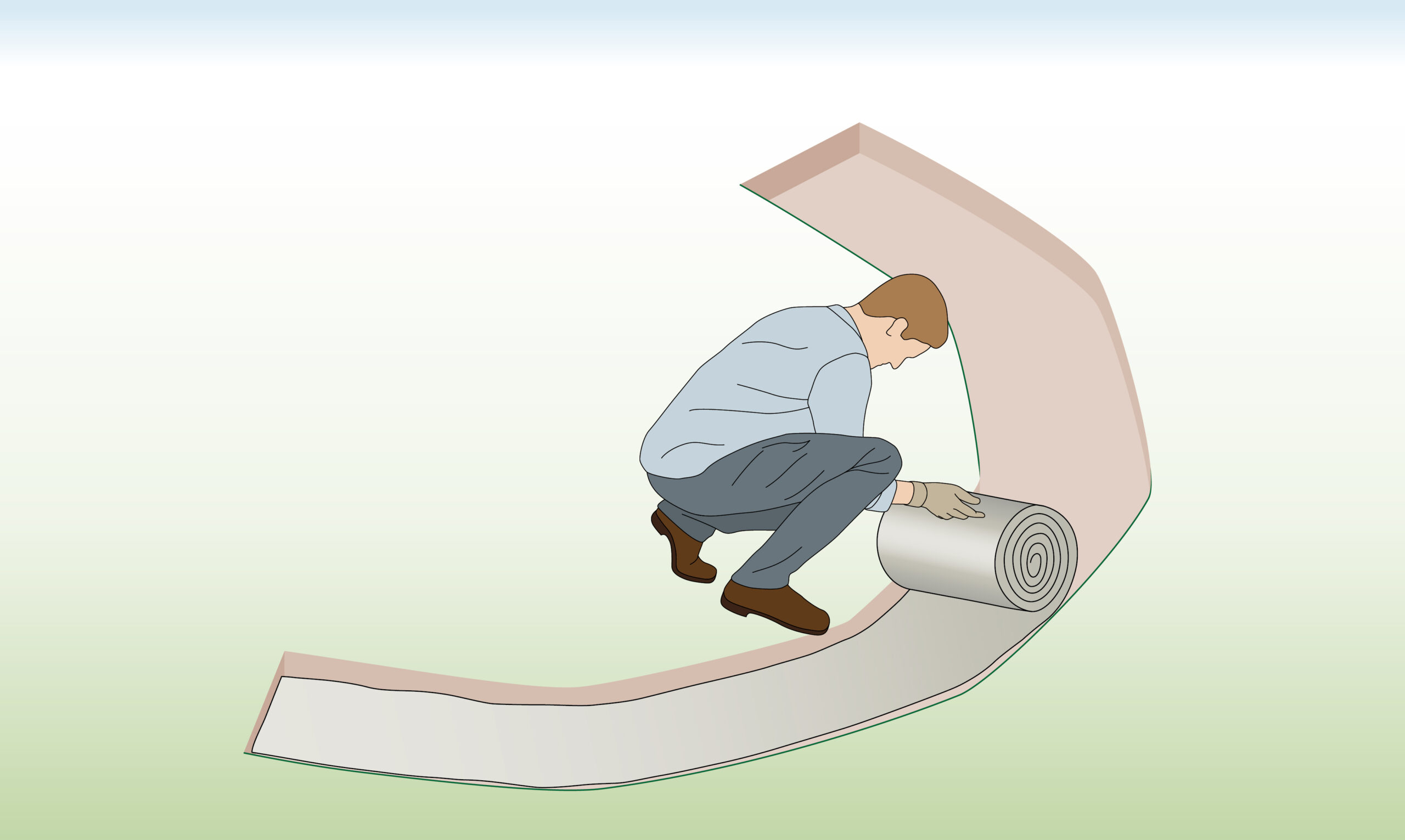

| Step 3 – Geotextile

|

Place a layer of geotextile on top of the soil to prevent weeds from growing through your structure after installation. |

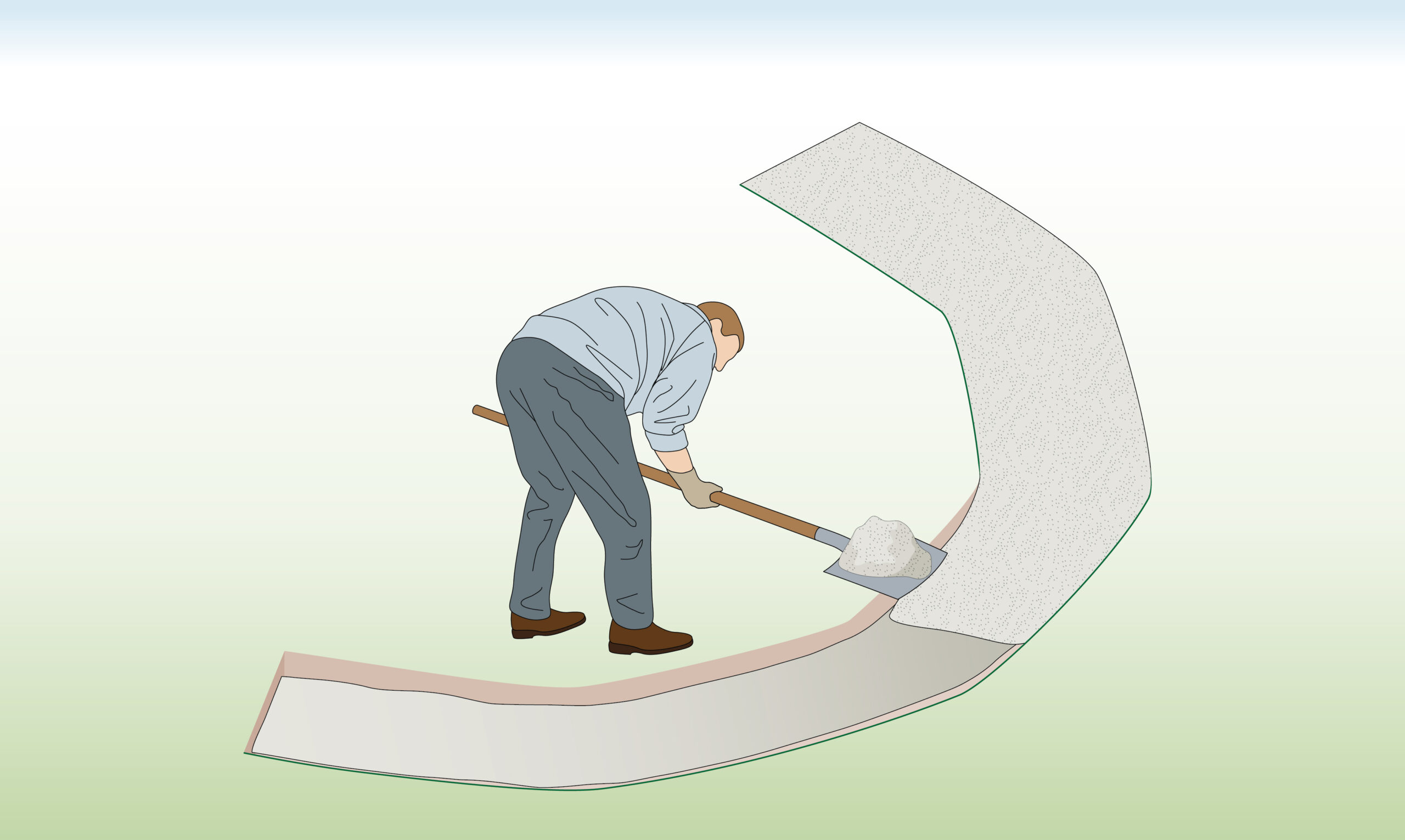

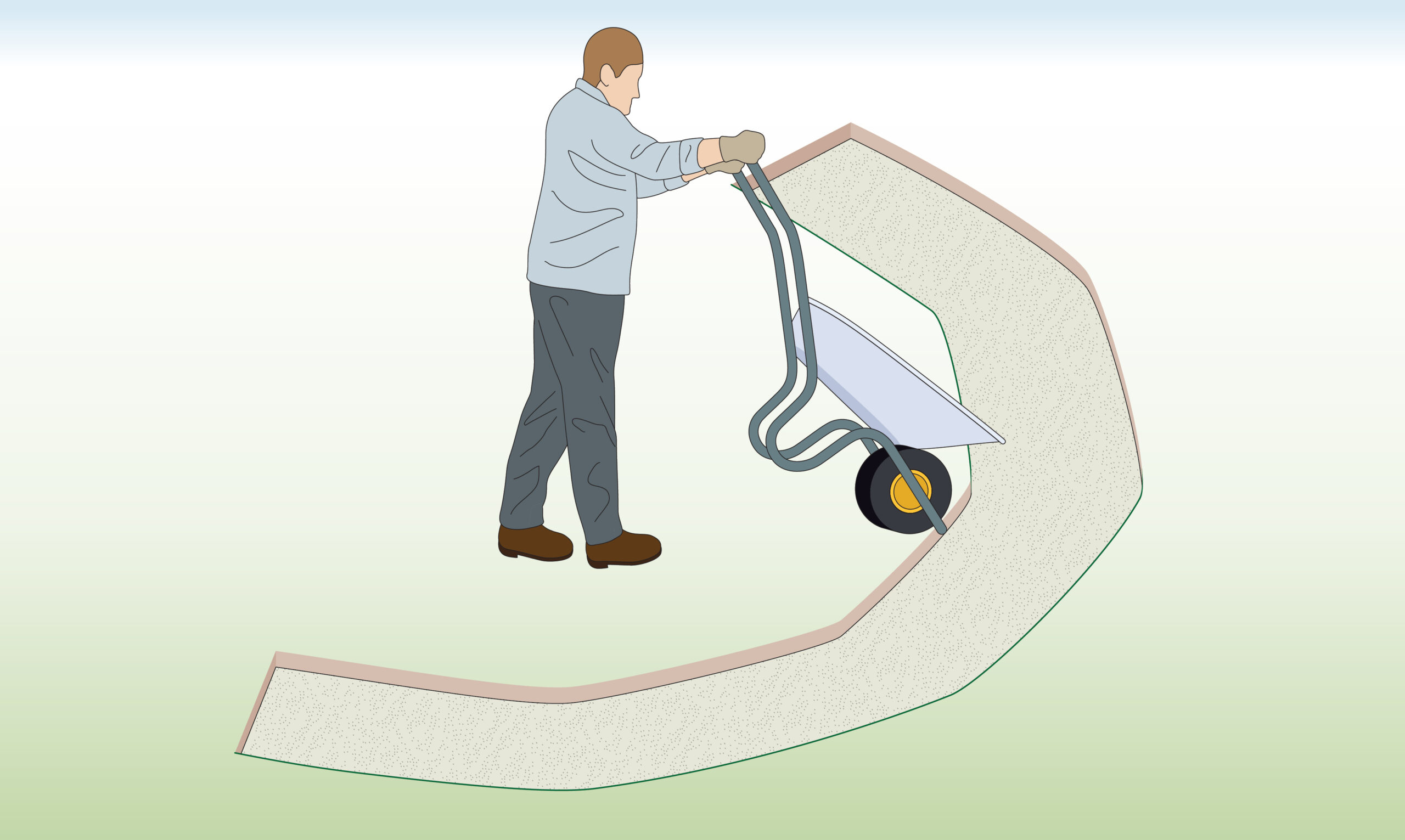

| Step 4 – Add Gravel or Basecourse

|

Add a layer of gravel or basecourse on top of the geotextile.

|

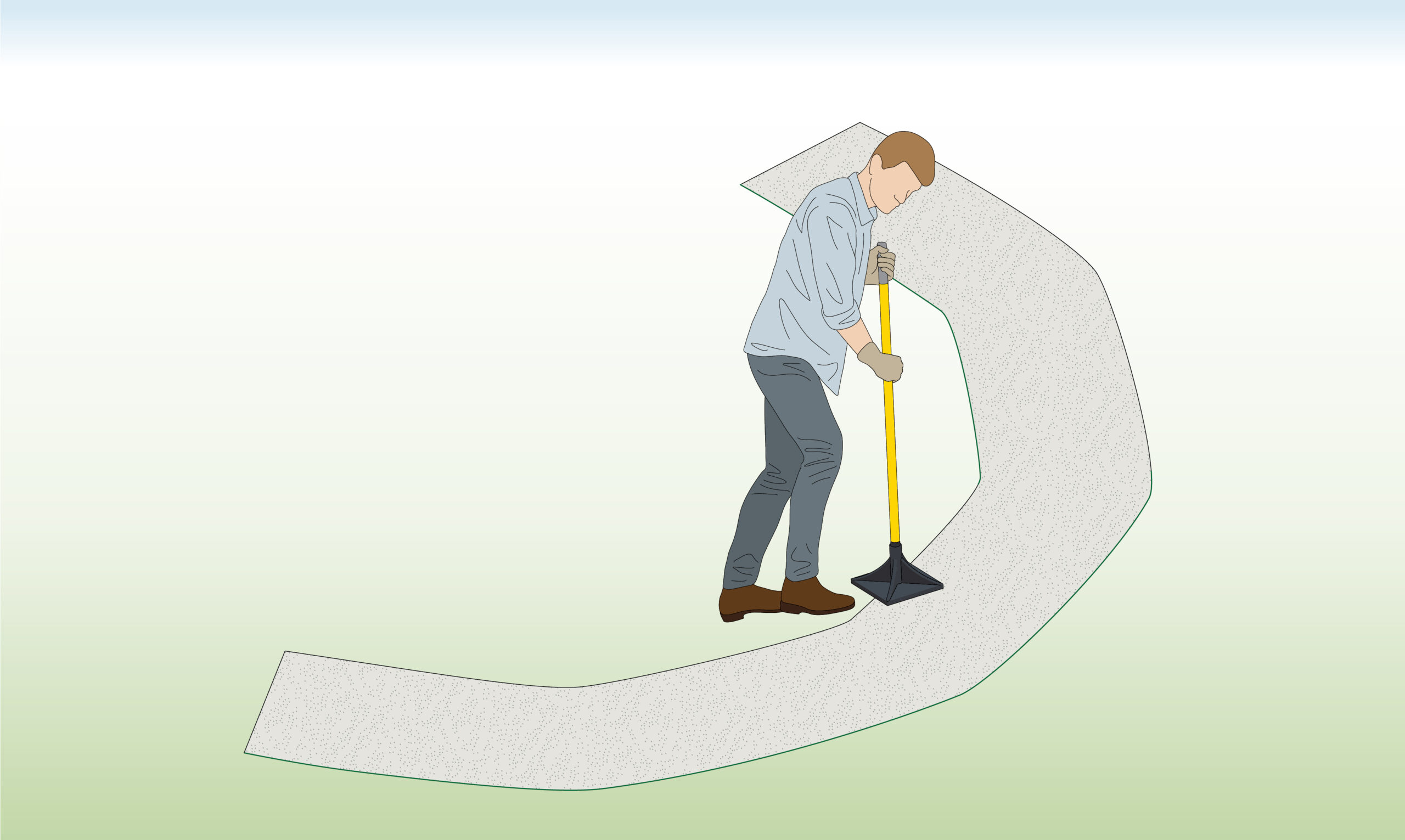

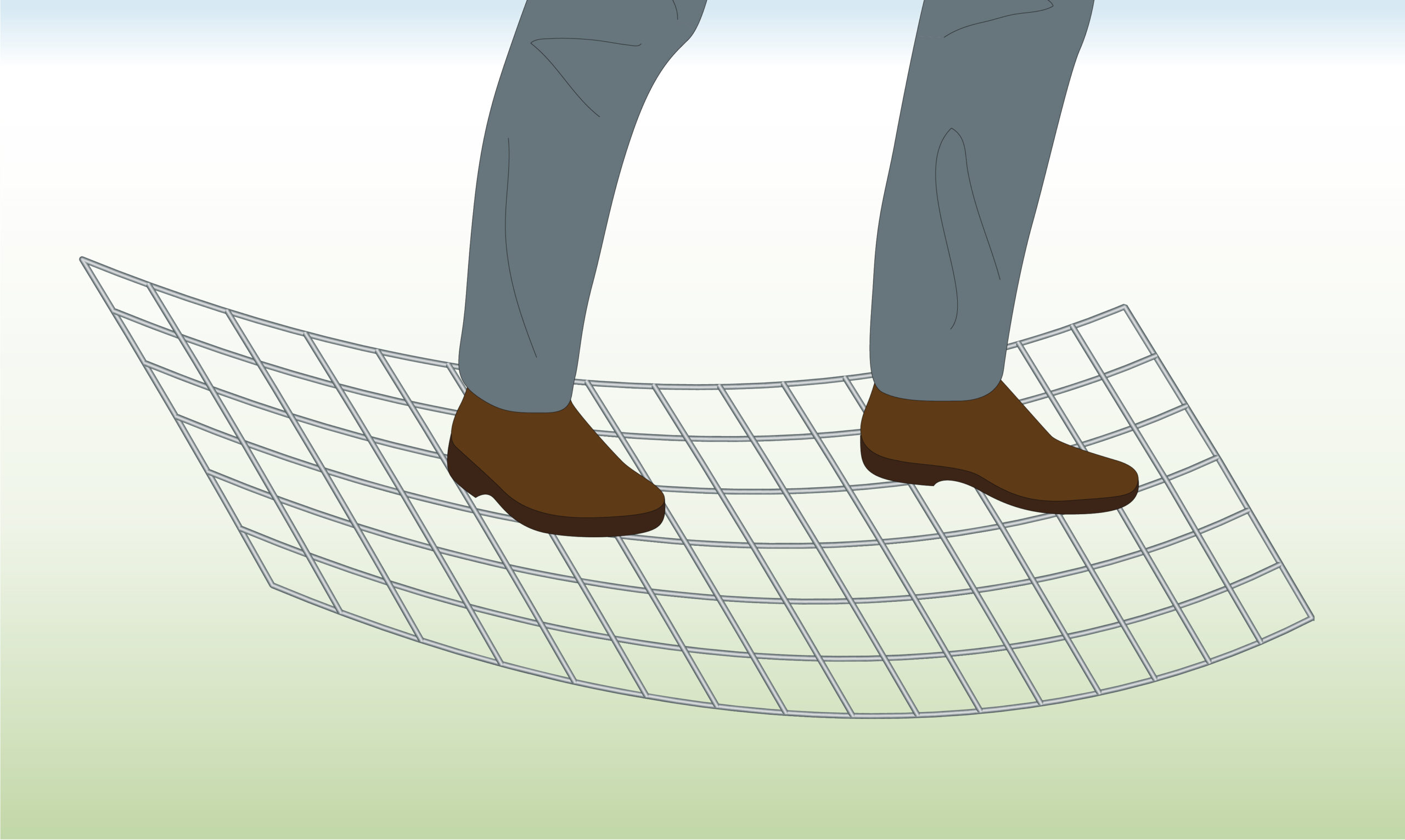

| Step 5 – Compact Gravel

|

Walk and stomp on the gravel to make it compact or use a base plate for bigger jobs. |

| Optional – Concrete foundation

|

Most low-level installations do not require a foundation but if you have a large amount of groundwater or the soil is weak, it may be needed. |

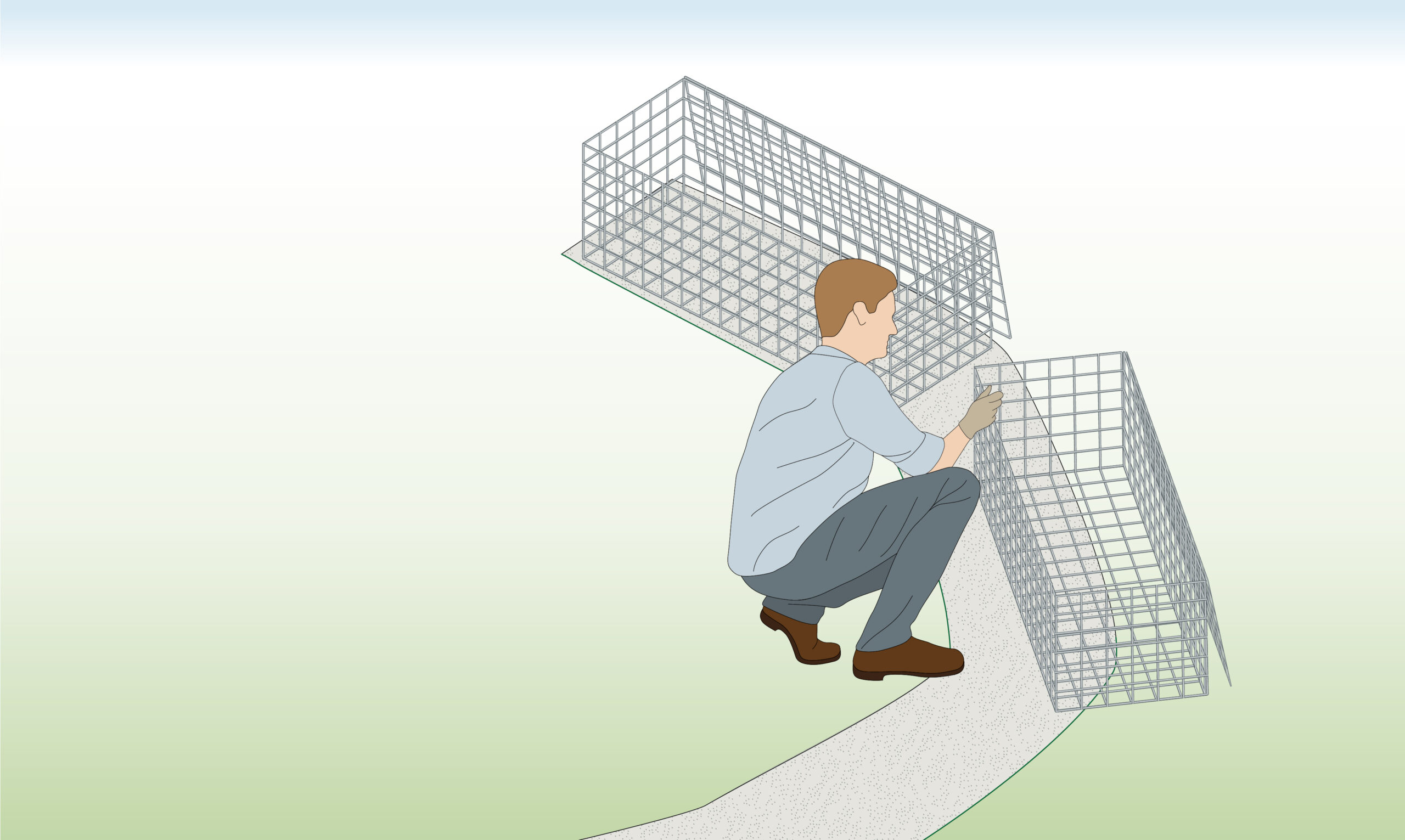

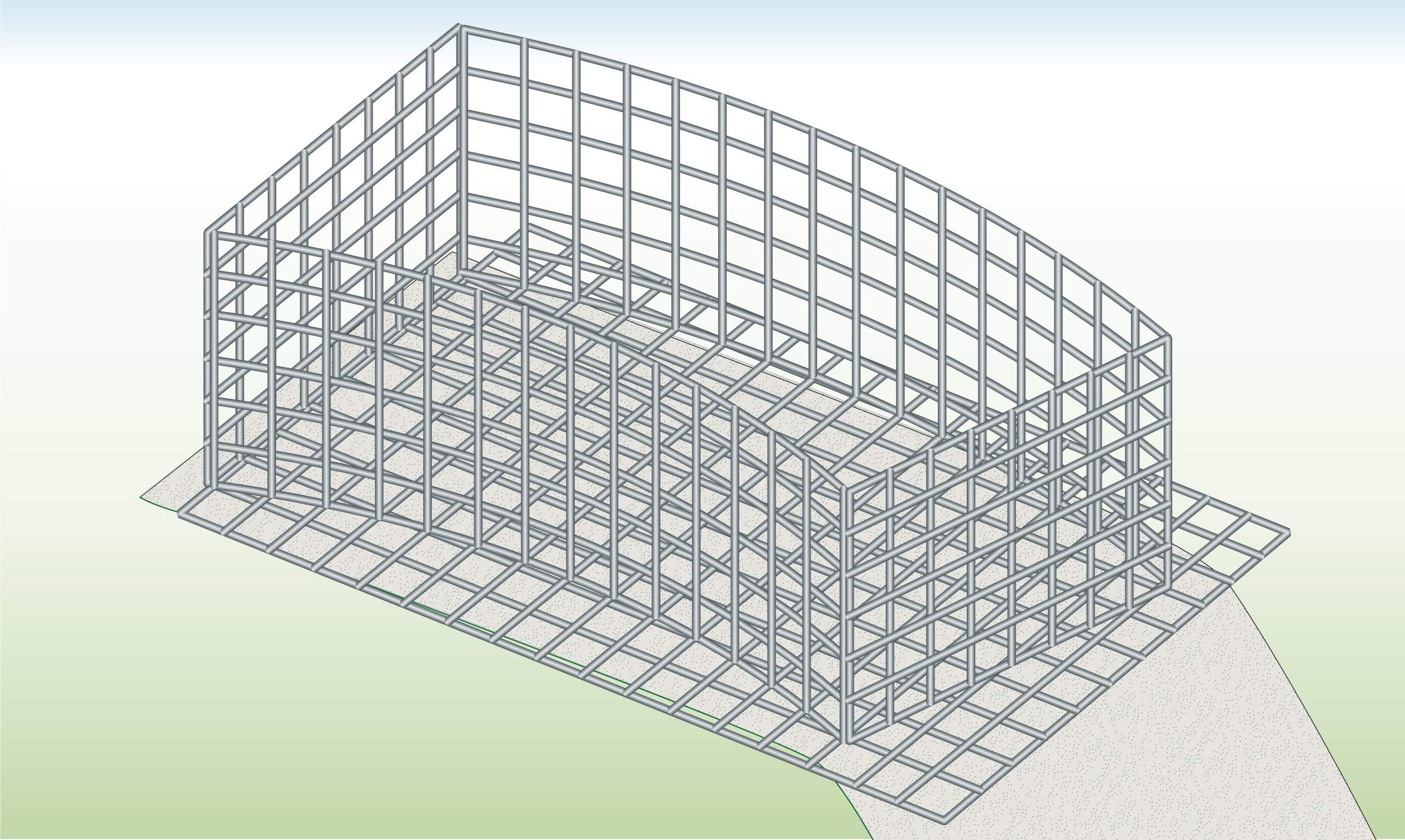

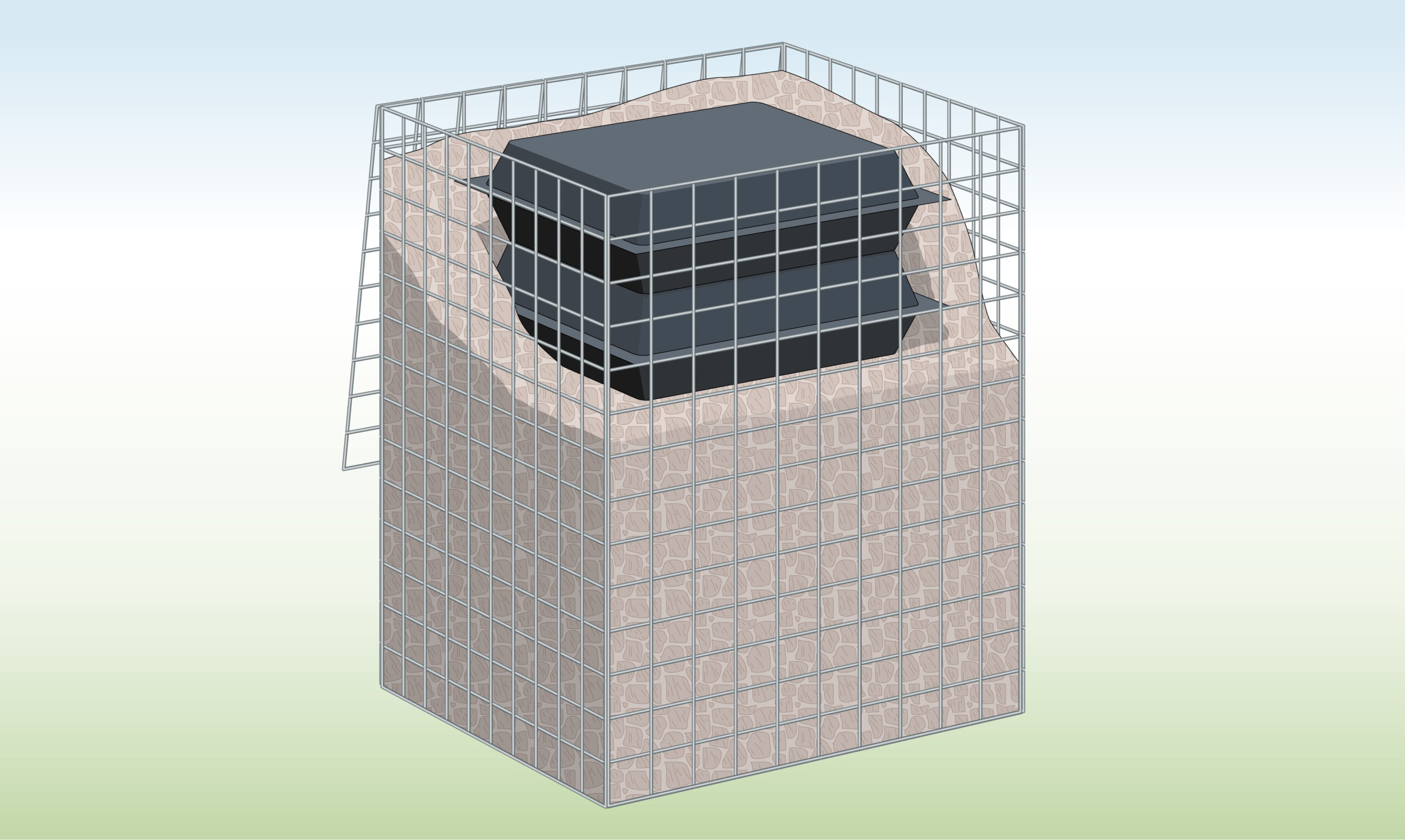

| Step 6 – Assemble

|

Assemble each of your baskets (download PDF) leaving the lid loose so you can fill them. |

| Step 7 – Put Into Position

|

Put them in place ensuring they are in the same position as when you took the measurements.

If the curve shape has changed since measuring, you may need to reorder additional materials. |

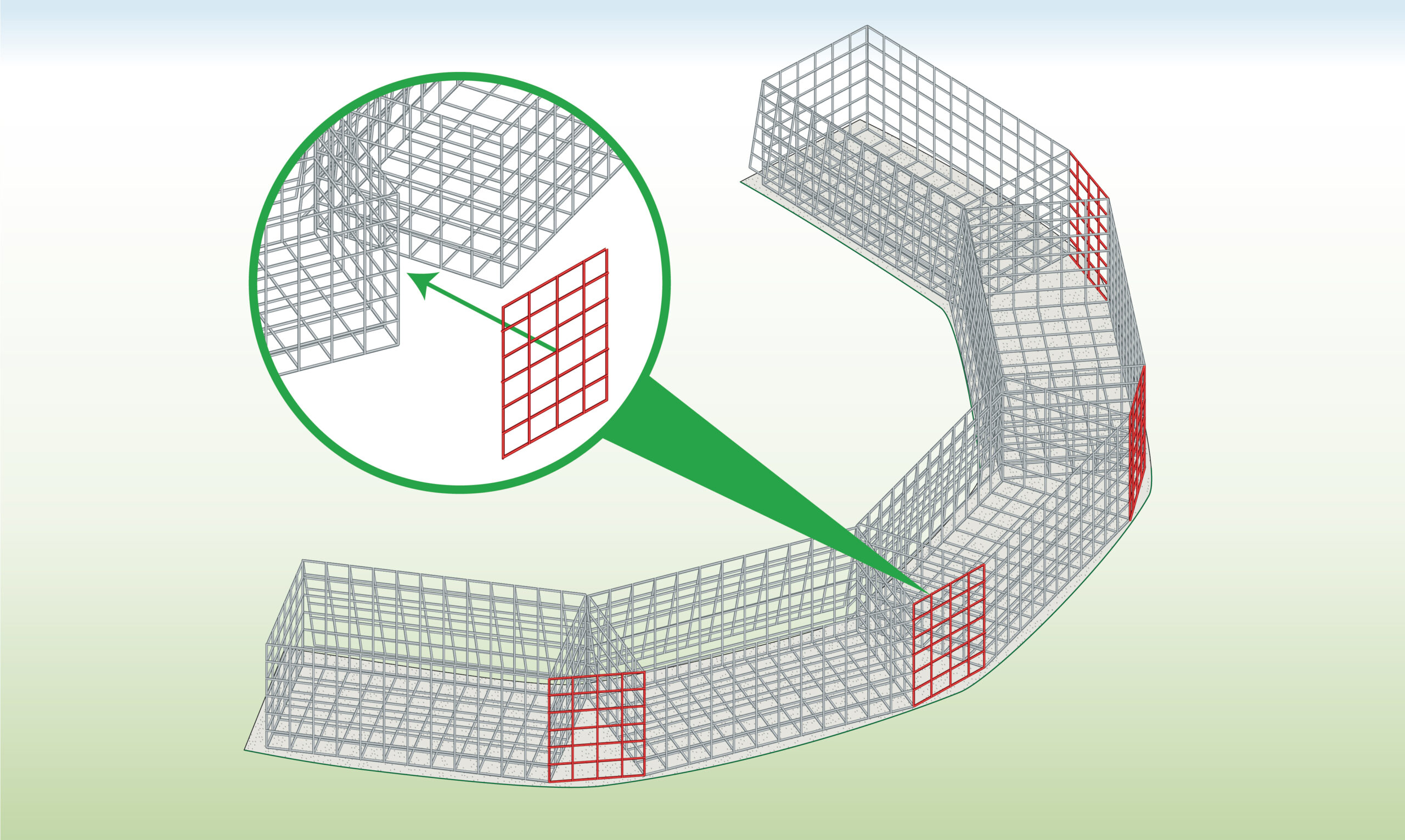

| Step 8 – Add Panels

|

Connect the back using panels.

We always suggest ordering a 1x1m spare panel which you can cut to size just in case the curve changes shape slightly. |

| Step 9 – Fill with Rocks

|

Fill with gabion stone (download PDF). |

| To Do | Explanation |

| Step 1 – Mark Area

|

Mark the area where you plan to install before placing your order.

If possible, keep the area marked until your order arrives to ensure the curve shape remains exactly the same.

It is possible to adjust the shape slightly after delivery but if the curve changes significantly, you may need to reorder new materials. |

| Step 2 – Dig

|

Dig until the ground is firm. Structures 1m tall or less are often placed directly on the ground but they will be more stable if placed on firm ground such as clay instead of the topsoil. |

| Step 3 – Geotextile

|

Place a layer of geotextile on top of the soil to prevent weeds from growing through your structure after installation. |

| Step 4 – Add Gravel or Basecourse

|

Add a layer of gravel or basecourse on top of the geotextile.

|

| Step 5 – Compact Gravel

|

Walk and stomp on the gravel to make it compact or use a base plate for bigger jobs. |

| Optional – Concrete Foundation

|

Most low-level installations do not require a foundation but if you have a large amount of groundwater or the soil is weak, it may be needed. |

| Step 6 – Assemble

|

Assemble each of your baskets (download PDF) leaving the lid loose so you can fill them. |

| Step 7 – Cut Mitre Corner

|

Using bolt cutters, cut the side of the first cage to create an opening for the second one to slot into.

Important: we suggest ordering cages 15cm – 30cm longer than you require after measuring. This allows for adjustments that may need to be made when installing. |

| Step 9 – Repeat Steps 6-8

|

Repeat this process, adjusting the position as you lay each cage to get the exact curve you require. |

| Step 9 – Fill with Stone

|

Once all of your cages are in place, fill them with gabion stone. (download PDF) |

| To Do | Explanation |

| Step 1 – Mark Area

|

Mark the area where you plan to install before placing your order.

If possible, keep the area marked until your order arrives to ensure the curve shape remains exactly the same. It is possible to adjust the shape slightly after delivery but if the curve changes significantly you may need to reorder new materials. |

| Step 2 – Dig

|

Dig until the ground is firm. Structures 1m tall or less are often placed directly on the ground but they will be more stable if placed on firm ground such as clay instead of the topsoil. |

| Step 3 – Geotextile

|

Place a layer of geotextile on top of the soil to prevent weeds from growing through your structure after installation. |

| Step 4 – Add Gravel or Basecourse

|

Add a layer of gravel or basecourse on top of the geotextile:

|

| Step 5 – Compact Gravel

|

Walk and stomp on the gravel to make it compact or use a base plate for bigger jobs. |

| Step 6 – Base Panels

|

Place panels on the ground along the entire length of your curved wall making sure the panels overhang the base that you have created. |

| Step 7 – Roll side panels into shape

|

Roll the panel around a car tire or similar curved object. Keep rolling until you get the circular shape you would like.

|

| Step 8 – Adjust Curve

|

You may need to tread on the panel after rolling it to adjust the curvature. |

| Step 9 – Put Side Panels into Position

|

Put the first inner, outer, back and front panels into position on top of the base panels.

When you attach the corners of the panels, they should stay in position. Add rocks or posts for added support during installation. |

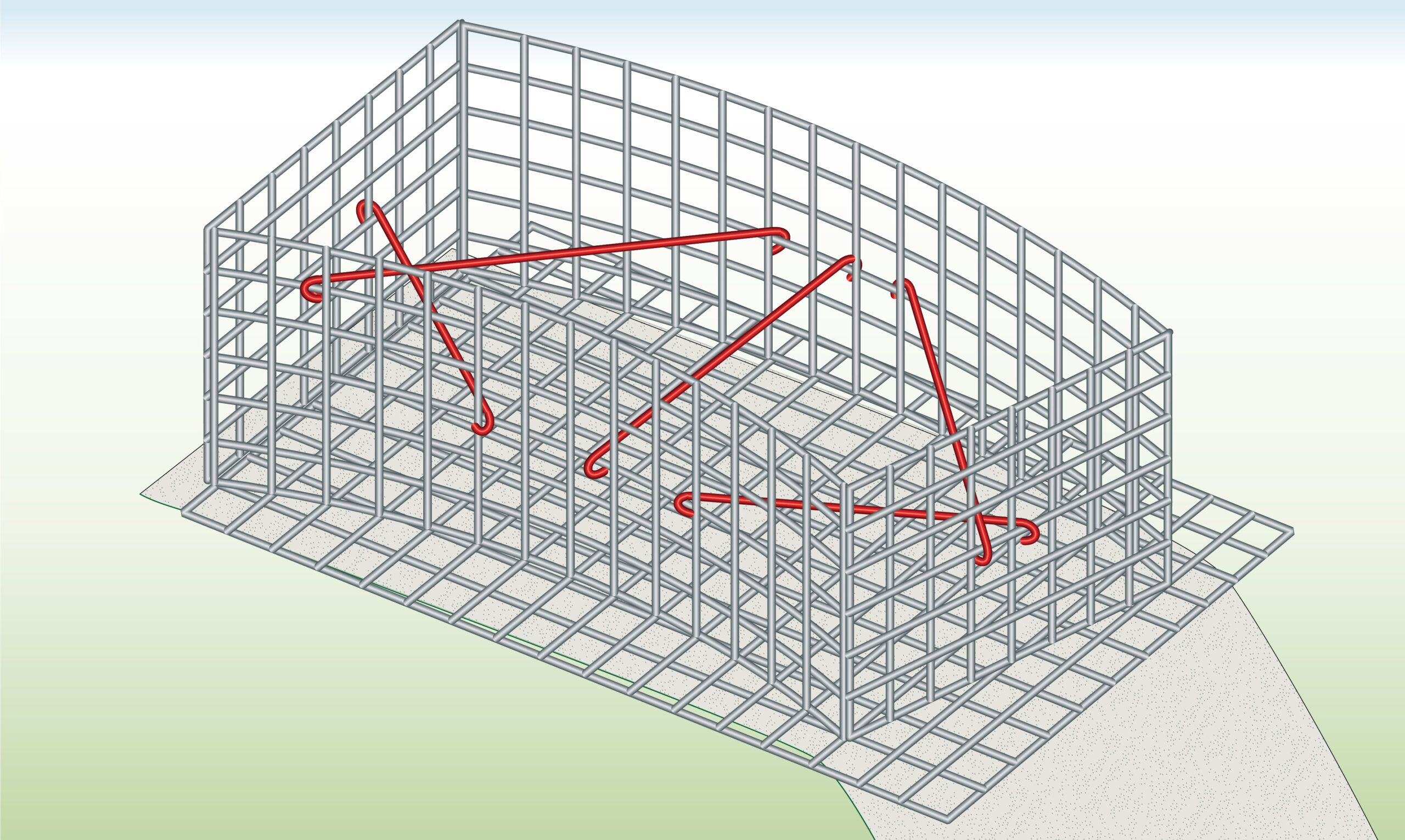

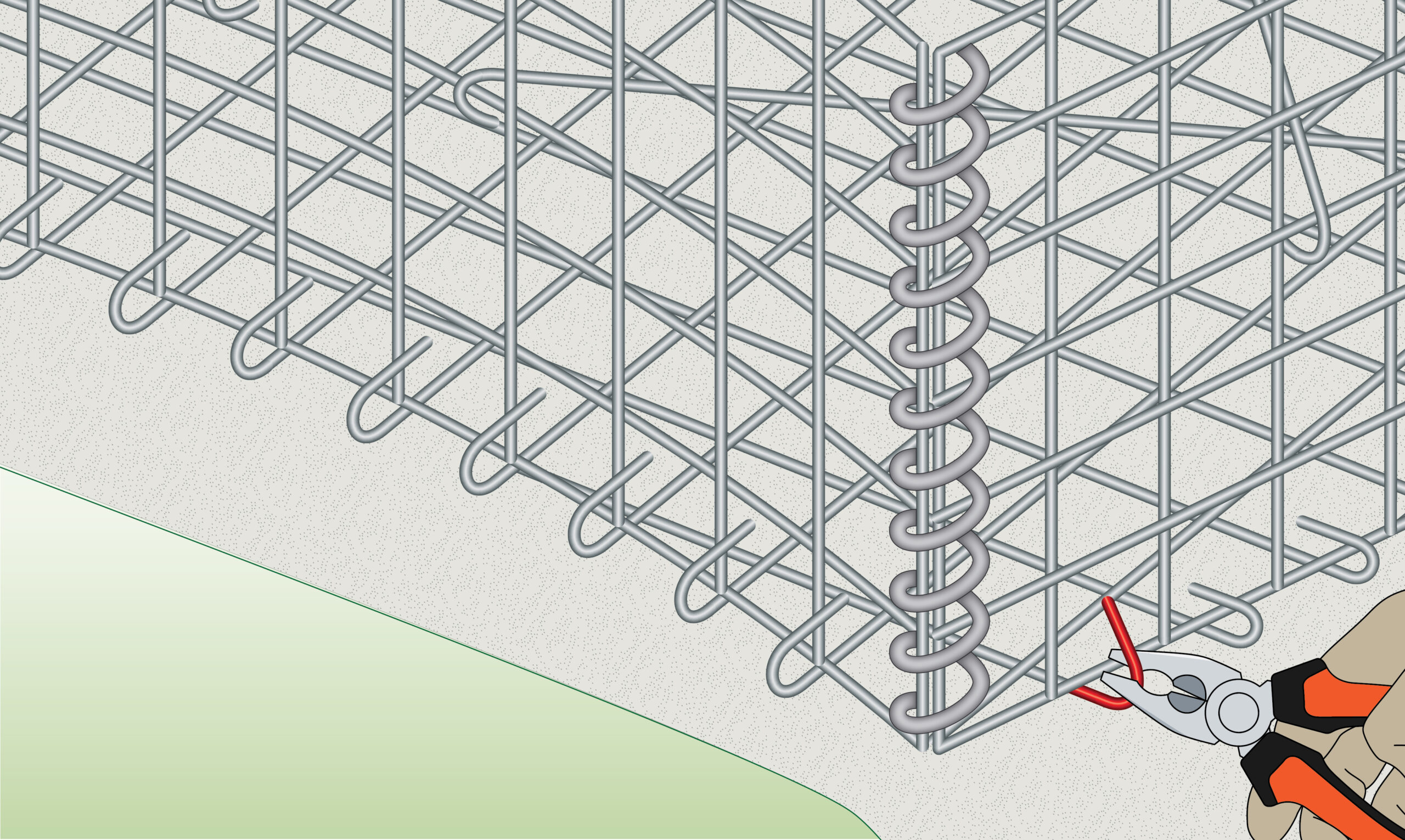

| Step 10 – Add Braces

|

Add braces for every meter of the wall. The braces should be installed about halfway up the height of the structure. This will increase stability and reduce bulging. |

| Step 11 – Cut Base

|

Cut the base panels so that the so that they follow the curve of the side panels, leaving roughly 5-10cm of extra wire that can be folded back into the cage. |

| Step 12 – Fold Base Wires

|

Fold the extra 5-10cm of wires back into the basket making sure they loop over the top of the side panel mesh. |

| Step 13 – Repeat Steps 6-11

|

Follow steps 6-11 until you have completed your installation. |

| Step 14 – Fill with Stone

|

Once all of your cages are in place, you can fill them with gabion stone (download PDF) |

Calculate Stone Quantity

- Use the guide below to calculate the amount of stone that you need to fill your gabion wall

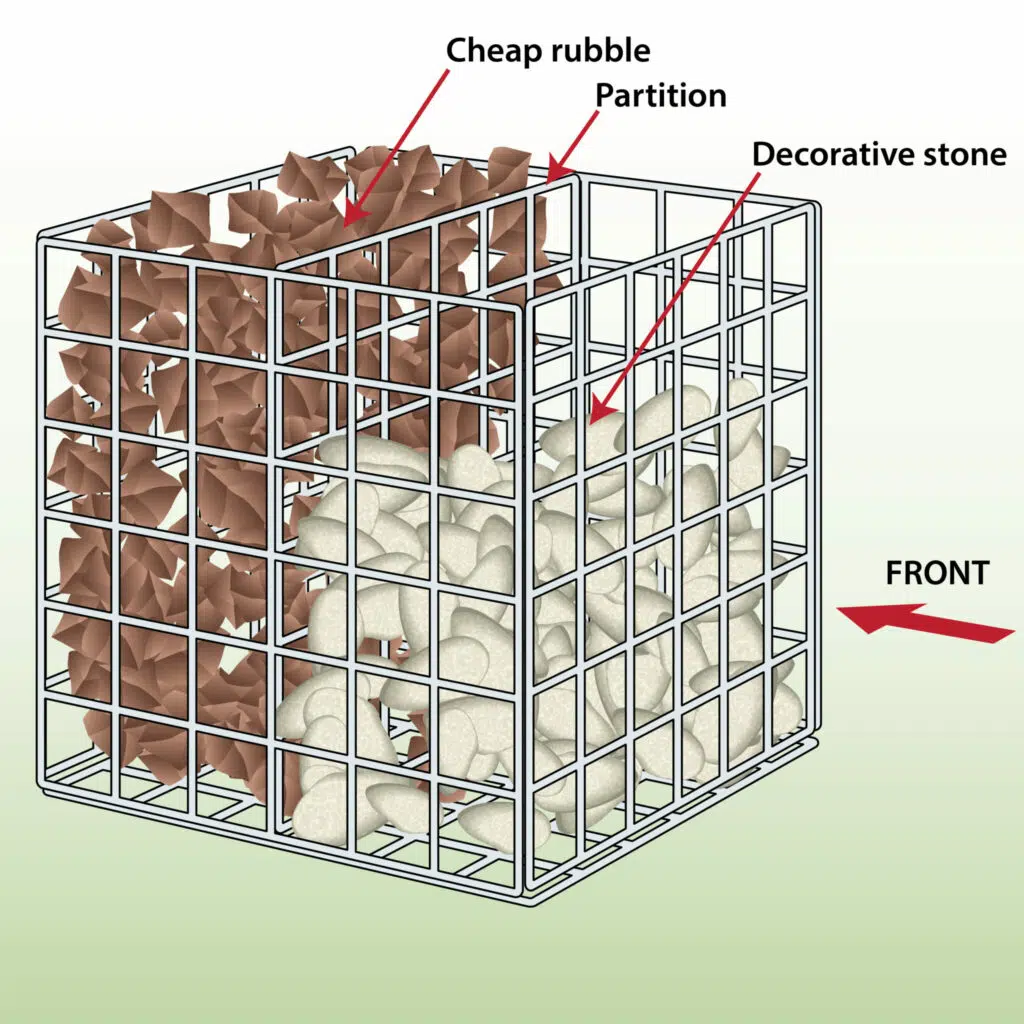

- You can use stone separating panels to reduce the amount of decorative rocks required and save money rubble-bag

| Gabion Wall Dimensions (cm) | Bulk Bags of Granite Stone Required | Bulk Bags of Granite Stone Required if using Partitions | Bulk Bags of Limestone Required | Bulk Bags of Limestone Required if using Partitions | ||

| 250cm | 110cm | 45cm | 2 | 1 | 2 | 1 |

| 250cm | 110cm | 45cm | 2 | 1 | 2 | 1 |

| 250cm | 110cm | 45cm | 2 | 1 | 2 | 1 |

| 250cm | 110cm | 45cm | 2 | 1 | 2 | 1 |

| 250cm | 110cm | 45cm | 2 | 1 | 2 | 1 |

| 556cm | 187cm | 97.5cm | 12 | 7 | 13 | 7 |

| 556cm | 187cm | 97.5cm | 12 | 7 | 13 | 7 |

| 556cm | 187cm | 97.5cm | 12 | 7 | 13 | 7 |

| 556cm | 187cm | 97.5cm | 12 | 7 | 13 | 7 |

| 556cm | 187cm | 97.5cm | 12 | 7 | 13 | 7 |

| 225cm | 120cm | 45cm | 2 | 1 | 2 | 1 |

| 225cm | 120cm | 45cm | 2 | 1 | 2 | 1 |

| 225cm | 120cm | 45cm | 2 | 1 | 2 | 1 |

| 225cm | 120cm | 45cm | 2 | 1 | 2 | 1 |

| 225cm | 120cm | 45cm | 2 | 1 | 2 | 1 |

| 560cm | 185cm | 97.5cm | 13 | 7 | 13 | 8 |

| 560cm | 185cm | 97.5cm | 13 | 7 | 13 | 8 |

| 560cm | 185cm | 97.5cm | 13 | 7 | 13 | 8 |

| 560cm | 185cm | 97.5cm | 13 | 7 | 13 | 8 |

| 560cm | 185cm | 97.5cm | 13 | 7 | 13 | 8 |

| 260cm | 240cm | 45cm | 3 | 2 | 3 | 2 |

| 260cm | 240cm | 45cm | 3 | 2 | 3 | 2 |

| 260cm | 240cm | 45cm | 3 | 2 | 3 | 2 |

| 260cm | 240cm | 45cm | 3 | 2 | 3 | 2 |

| 260cm | 240cm | 45cm | 3 | 2 | 3 | 2 |

| 932cm | 362cm | 97.5cm | 24 | 13 | 26 | 14 |

| 932cm | 362cm | 97.5cm | 24 | 13 | 26 | 14 |

| 932cm | 362cm | 97.5cm | 24 | 13 | 26 | 14 |

| 932cm | 362cm | 97.5cm | 24 | 13 | 26 | 14 |

| 932cm | 362cm | 97.5cm | 24 | 13 | 26 | 14 |

| 220cm | 220cm | 45cm | 3 | 2 | 3 | 2 |

| 220cm | 220cm | 45cm | 3 | 2 | 3 | 2 |

| 220cm | 220cm | 45cm | 3 | 2 | 3 | 2 |

| 220cm | 220cm | 45cm | 3 | 2 | 3 | 2 |

| 220cm | 220cm | 45cm | 3 | 2 | 3 | 2 |

| 815cm | 415cm | 97.5cm | 25 | 15 | 27 | 16 |

| 815cm | 415cm | 97.5cm | 25 | 15 | 27 | 16 |

| 815cm | 415cm | 97.5cm | 25 | 15 | 27 | 16 |

| 815cm | 415cm | 97.5cm | 25 | 15 | 27 | 16 |

| 815cm | 415cm | 97.5cm | 25 | 15 | 27 | 16 |