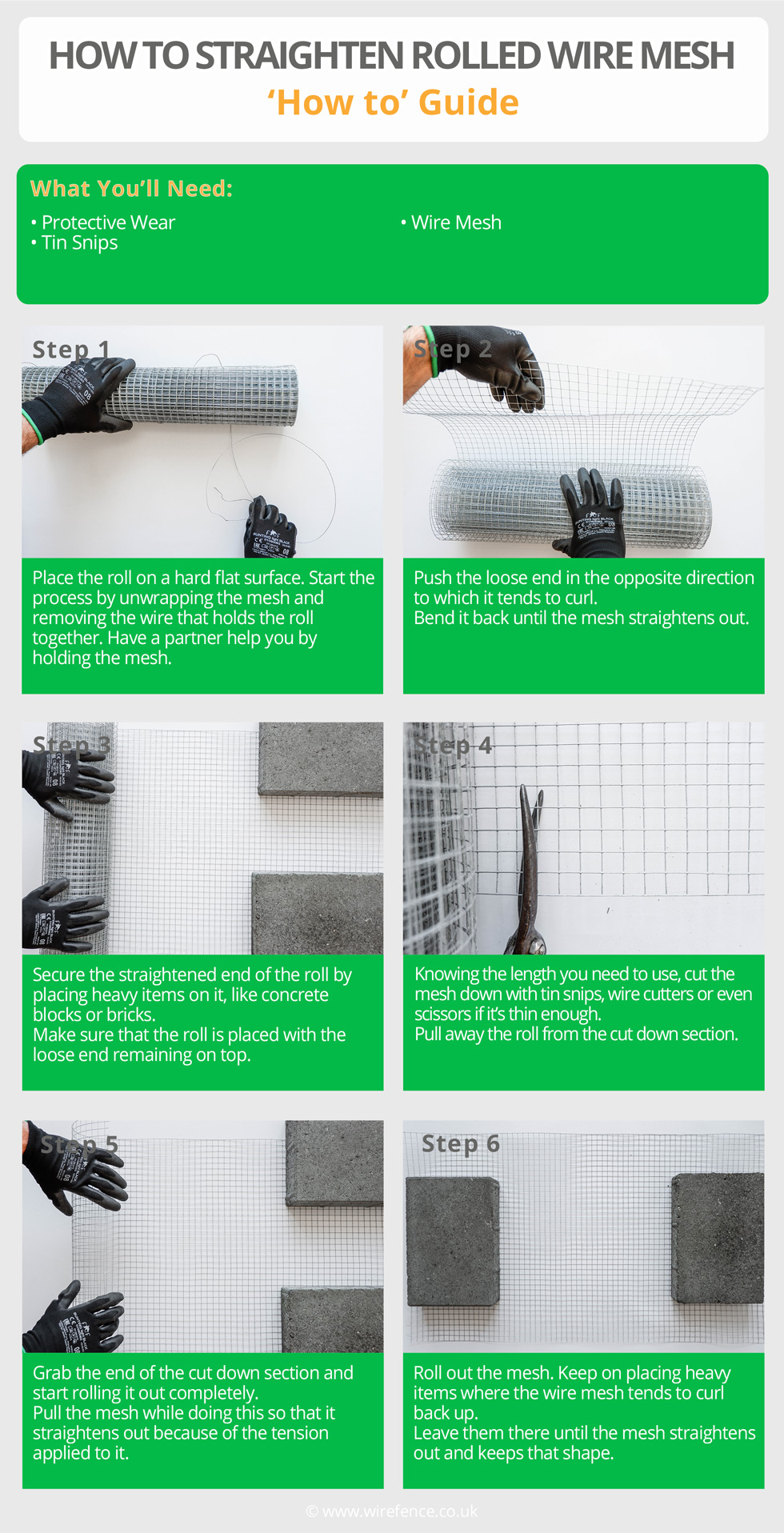

How to Straighten Rolled Wire Mesh

Ever wondered how to straighten rolled wire mesh? Below you can find instructions on how to do it yourself.

OVERVIEW

- Experience Required: Medium

- Tools Required: Protective Wear, Tin Snips

- Materials Required: Wire Mesh

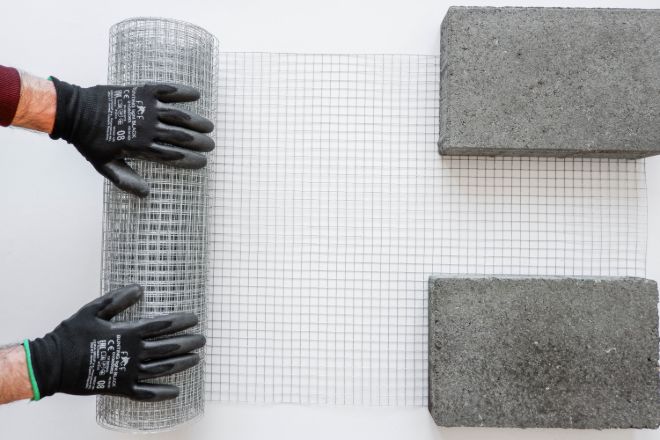

STEP 1: Unwrap the Wire Mesh

- Place the roll on a hard flat surface, preferably concrete.

- Start the process by unwrapping the mesh and removing the wire that holds the roll together.

- Have a partner help you by holding the mesh as it will tend to bounce back.

STEP 2: Bend the Loose End Back

- Push the loose end in the opposite direction to which it tends to curl.

- Bend it back until the mesh straightens out.

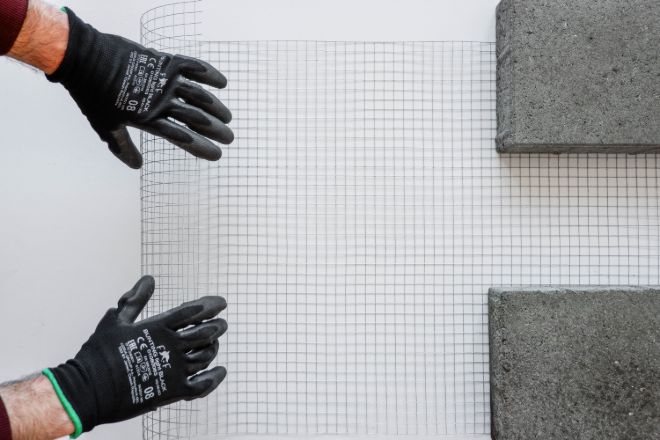

STEP 3: Secure the Straightened End

- Secure the straightened end of the roll by placing heavy items on it, like concrete blocks or bricks.

- Make sure that the roll is placed with the loose end remaining on top.

STEP 4: Cut the Mesh to Size

- Knowing the length you need to use, cut the mesh down with tin snips, wire cutters or even scissors if it’s thin enough.

- Pull away the roll from the cut down section.

STEP 5: Roll Out the Mesh Completely

- Grab the end of the cut down section and start rolling it out completely.

- Pull the mesh while doing this so that it straightens out because of the tension applied to it.

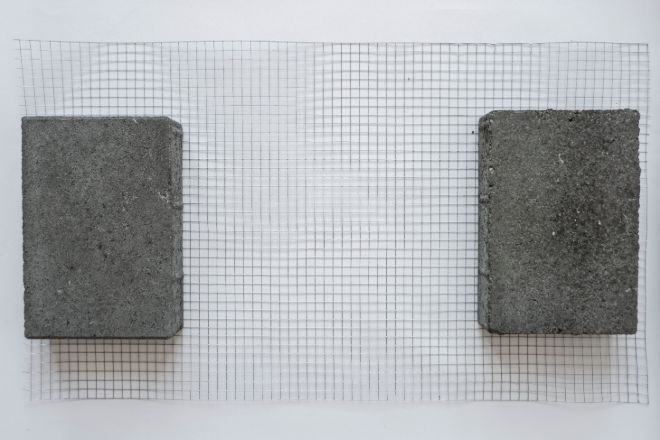

STEP 6: Leave Heavy Objects on It

- Roll out the mesh until you reach the end of the section you previously cut down from the roll.

- Keep on placing heavy items where the wire mesh tends to curl back up.

- Leave them there until the mesh straightens out and keeps that shape.

TIPS

- The thicker the wire, the more resistant the mesh will be to being straightened out and will be holding the rolled up shape instead.

- You may need more or heavier weights to definitively straighten out a heavyweight mesh.

- It’s easier if you work with a partner who can prevent the mesh from jumping back to its rolled up state as you move along its length and place the weights on top.

FURTHER READING